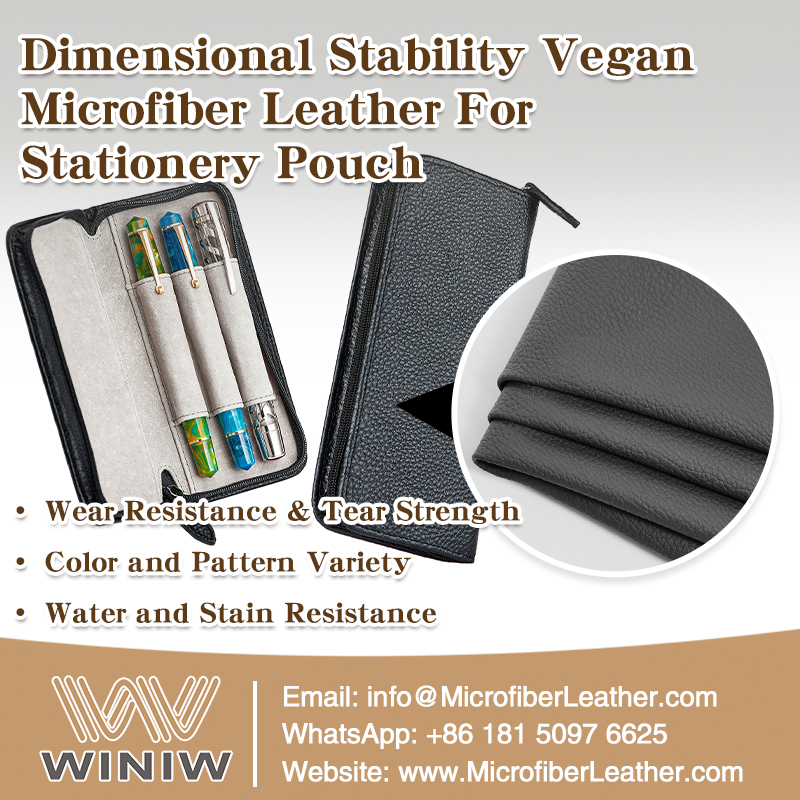

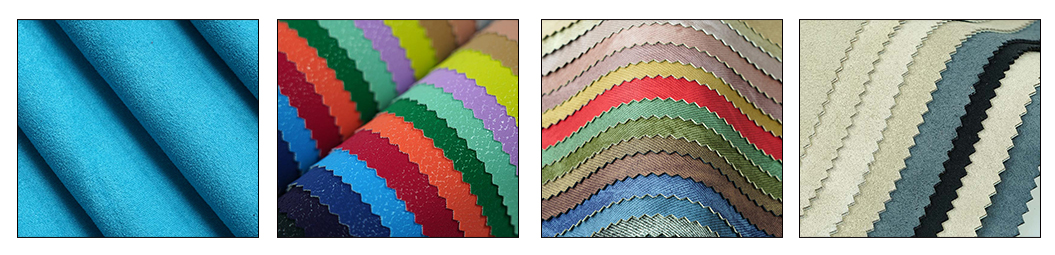

The process of designing and making artificial leather materials in making stationery bags involves several steps, including material selection, cutting, sewing and decorating. First of all, it is necessary to select the right artificial leather material, choosing the right type according to the usage and appearance requirements, such as polyvinyl chloride (PVC), polyurethane (PU) or polyethylene (PE). These materials usually have good abrasion resistance and water resistance, and are suitable for making durable stationery bags.

During the design stage, the designer will sketch and determine the style and size of the stationery bag according to the requirements. For example, they can be designed as rectangular or backpack type to suit different usage scenarios.The design is then translated into the actual bag. Next, the design is transformed into an actual model and samples are made Sampling.

In the production process, the required components, such as the body, flap and straps, are first cut from the selected faux leather material

. The cut edges need to be trimmed for subsequent stitching and decoration

The components are then bonded or glued to each other or to the bag. The components are then glued or sewn together, zips and other fixings are fitted.

For added aesthetics, the surface can be dyed or finished to give it a richer colour and texture. The overall texture of the product can also be enhanced by adding decorative elements such as buttons or embroidery.

Finally, the finished stationery bags are cleaned and organised for packaging and sale. The whole process requires delicate handling and in-depth knowledge of material properties to ensure the quality and durability of the finished product.

The process requires delicate handling and in-depth knowledge of material properties to ensure the quality and durability of the finished product.

Scan to wechat: