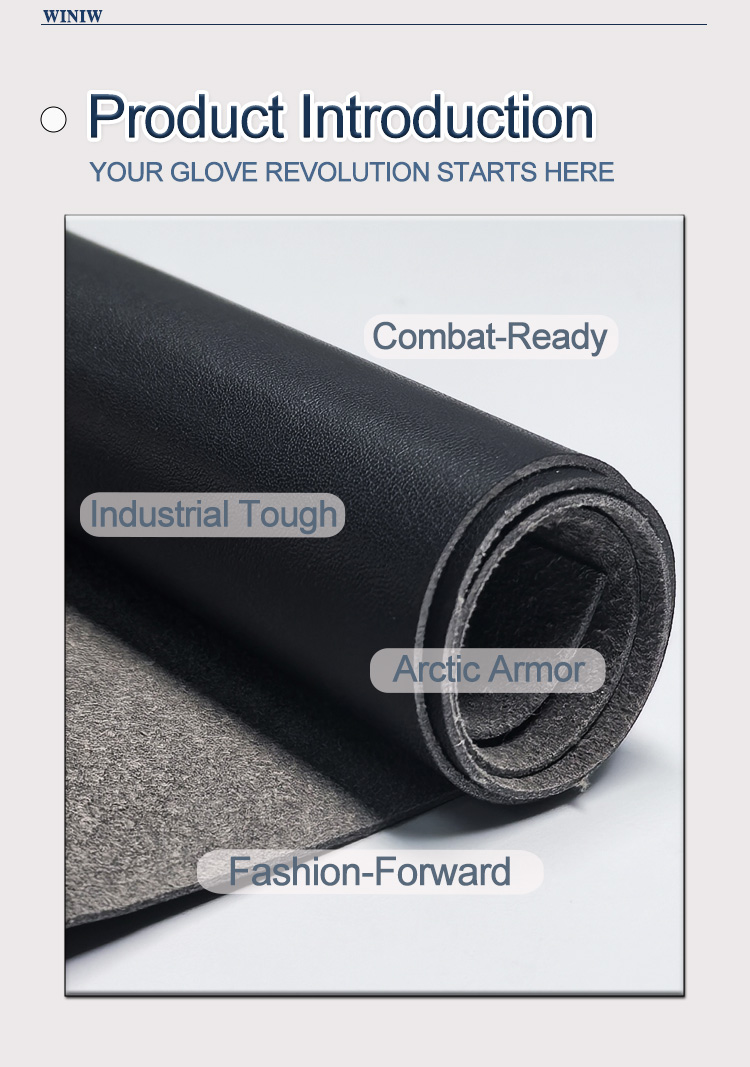

Material Introduction

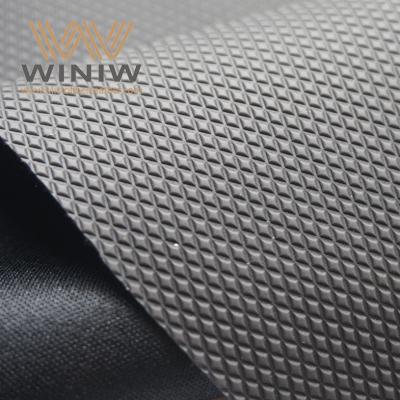

WINIW’s Compression-Resistant Industrial-Grade PU Leather is engineered to safeguard hands in high-pressure environments where crushing forces threaten both safety and productivity. This advanced synthetic material combines a shock-absorbing foam substrate, a high-tensile polyurethane reinforcement grid, and a diamond-textured surface coating to disperse compressive loads up to 600 kPa—far exceeding standard industrial glove materials.

Certified to ANSI/ISEA 105 and EN 388 standards, it resists permanent deformation, pinch injuries, and impact fatigue even after prolonged exposure to heavy machinery, hydraulic systems, or falling debris. Vegan and sustainably produced, it integrates seamlessly into glove designs that demand uncompromising protection without sacrificing dexterity, ensuring workers in construction, metalworking, and heavy logistics can grip, lift, and operate with confidence under extreme compressive stress.

Material Specification

| Material | Microfiber PU Leather |

| Width | 54"; 1.37m |

| Color | Red, Black, Brown, Green, accept customize |

| Feature | Wear resistant, Waterproof, Anti-Mildew, Flexible |

| Thickness | 0.6mm-2.4mm, accept customize |

| Delivery time | Usually within 15 - 25 days |

| MOQ | 300 meters |

| Production Capacity | 1,000,000 meters monthly |

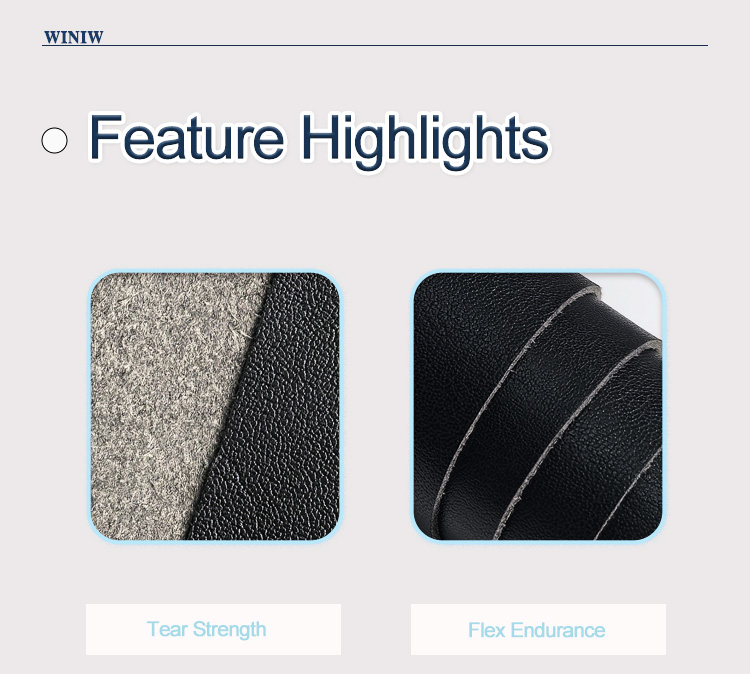

Material Feature

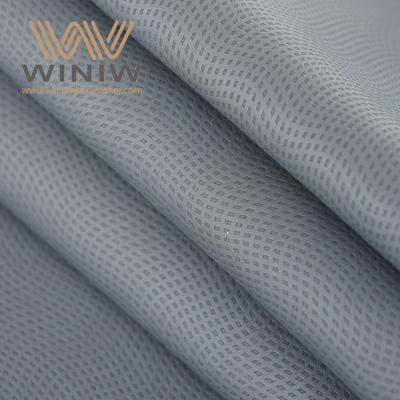

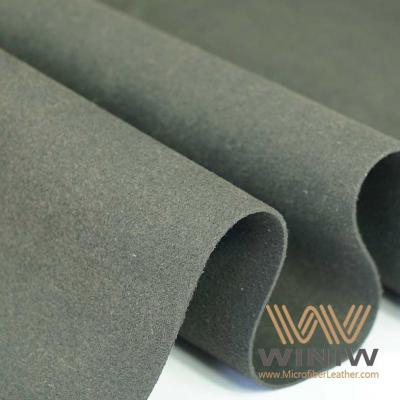

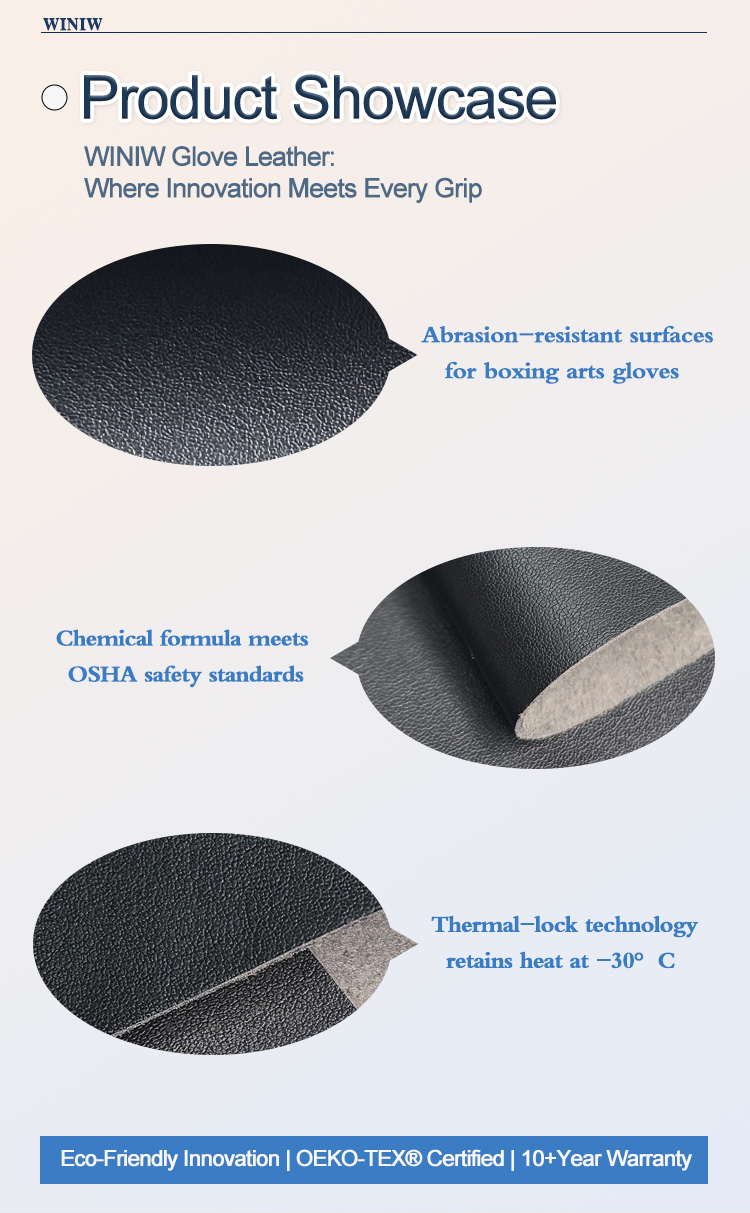

The core of this PU Leather’s compression resistance lies in its tri-layer defense: a viscoelastic foam base absorbs kinetic energy from sudden impacts, while a hexagonal polyurethane lattice embedded mid-layer redistributes sustained pressure across the material’s surface. The top layer, reinforced with silica-infused nanocoatings, resists abrasion and oil penetration that could weaken structural integrity. Tested to endure 15,000+ compression cycles at 400 kPa, it prevents thinning or cracking common in conventional synthetics.

Operating seamlessly from -25°C to 85°C, it remains flexible in sub-zero logistics warehouses and heat-intensive forging workshops. Anti-slip micro-suction cups on the palm enhance grip when handling greasy tools or vibrating machinery, while breathable perforations along the fingers reduce sweat-induced degradation. Anti-static properties ensure debris-free performance in dusty environments, and UV-resistant pigments maintain color stability for long-term outdoor use.

WINIW Factory Material Showcase

Application Scenarios

WINIW’s Compression-Resistant PU Leather is indispensable for gloves confronting relentless pressure across industries. Construction workers operating pile drivers or hydraulic crushers rely on its ability to withstand vibrations and accidental pinching during steel beam installations. Automotive assembly line technicians use gloves reinforced with this material to safely handle engine blocks under robotic press systems. Mining crews deploy it in gloves that protect against rock compression during tunnel drilling, while warehouse operators grip heavy metal crates and robotic palletizers without fear of material fatigue.

In the energy sector, oil rig technicians depend on its cold-weather resilience and crush-proof design for pipeline maintenance, and disaster response teams trust gloves made from this material to navigate collapsed structures where shifting debris poses constant compression risks. Even in aerospace manufacturing, it shields hands during the high-pressure assembly of turbine components, proving its versatility across the most demanding industrial landscapes.

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

Q: Is this leather eco-friendly?

A: Yes! Our synthetic leather is crafted with sustainable practices, offering a cruelty-free and environmentally conscious alternative.

Q: How durable is the material?

A: Designed for longevity, it resists scratches, fading, and wear while maintaining its soft, skin-like texture.

Q: Can it be customized for different designs?

A: Absolutely. It’s available in varied colors and finishes, adapting seamlessly to creative projects and industrial needs .

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com