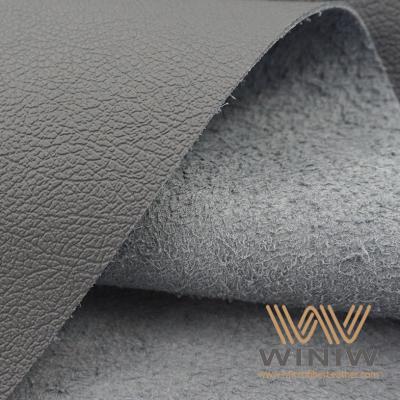

The consistent grain pattern of WINIW microfiber leather gives it a premium look, enhancing the overall aesthetic of the car's interior.

Product Specification

|

Material |

Microfiber Leather |

|

Composition |

55 Nylon + 45% Polyurethane |

|

Brand Name |

WINIW |

|

Thickness |

1.2mm, 0.6mm, 0.8mm, 1mm, 1.4mm, 1.6mm |

|

Width |

54", 137cm |

|

Color |

Black, Red, Grey, accept customize |

|

Use |

Car, Car Seat, Car interiors |

|

Feature |

Breathable, Anti-Mildew, Skin-friendly |

|

Place of Origin |

China |

|

Customized |

Yes |

|

Delivery time |

Usually within 15-20 days. |

|

MOQ |

300 meters |

|

Packaging Details |

30/50 Meters per Roll. Or customized |

|

Production Capacity |

1,000,000 meters monthly |

Key Property

- Less elongation: The low elongation of the microfiber leather is very significant, which means that even after a long period of use and pulling, it will not lose its shape and still retain its original shape, so that the overall appearance will always be beautiful.

- Good anti-hydrolysis ability: PU leather is extremely resistant to hydrolysis. This means that it retains its quality and appearance even in humid environments. This is important for a variety of outdoor items and shoes, as they are often exposed to water and moisture.

-

UV-resistant: Faux leather is made with advanced technology that protects it from fading and deterioration caused by sunlight exposure. This means that it retains its color and texture for longer periods of time, even when exposed to the elements.

Application

Seat covering: Microfiber leather is often used as a covering material for car seats due to its high folding fastness, tear strength and peel strength, making the seat more durable and durable. In addition, the softness and comfort of microfiber leather also make the driving experience even better.

China Leading Microfiber Leather Manufacturer

Quanzhou Winiw Import And Export Co., Ltd. is a professional supplier in leather fabric. Our business scope covers synthetic faux leather, imitation leather, PU leather, PVC leather and microfiber leather, which are widely used in shoes, handbags, luggage, furniture, upholstery, garments, decorations and so on.

We always produce as per customers specification requirements as thickness, color, textures grain, hand feel, softness, etc. We also provide some several series with large color selections in stock for immediate delivery.

Production Process

Microfiber leather is a combination of micro fiber and PU leather surface. This leather is made of a kind of microfiber by needling technology to make a three-dimensional structure network of non-woven fabric, and then through wet processing, PU resin immersion, skin dyeing and finishing processing technology.

FAQ

-

Q: Do you check all the goods before delivery?

A: Yes, we have 100% inspection before delivery.

-

Q: Can you develop new colors for us ?

A: Yes we can. You can provide us color samples, then we can develop the lab dips for your confirmation Within 7-10days.

-

Q: Is your material eco-friendly?

A: Yes, our materials is eco-friendly, comply with EU Reach regulations.

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com