PVC artificial leather, microfiber leather, and real leather are three common important materials used as automotive interior leather. As a leather material for automotive interiors, the industry has some basic performance requirements for it, such as light resistance, heat and humidity resistance, color fastness to rubbing, resistance to rubbing damage, flame retardancy, tensile strength, tear strength, and sewing strength. , Feel, durable, easy to clean, etc.

PVC artificial leather was the first to be used as a vehicle seat covering material. PVC artificial leather is also called PVC coated fabric. It is a material formed by mixing and coating PVC powder resin, plasticizer and ultraviolet absorber and other additives on the base fabric. The production process of PVC leather and PVC wear-resistant leather is similar, but the properties of the two materials are different, and there are some differences in the formulation of the PVC dense layer and surface layer. At present, the commonly used production processes of PVC artificial leather are calendering and coating.

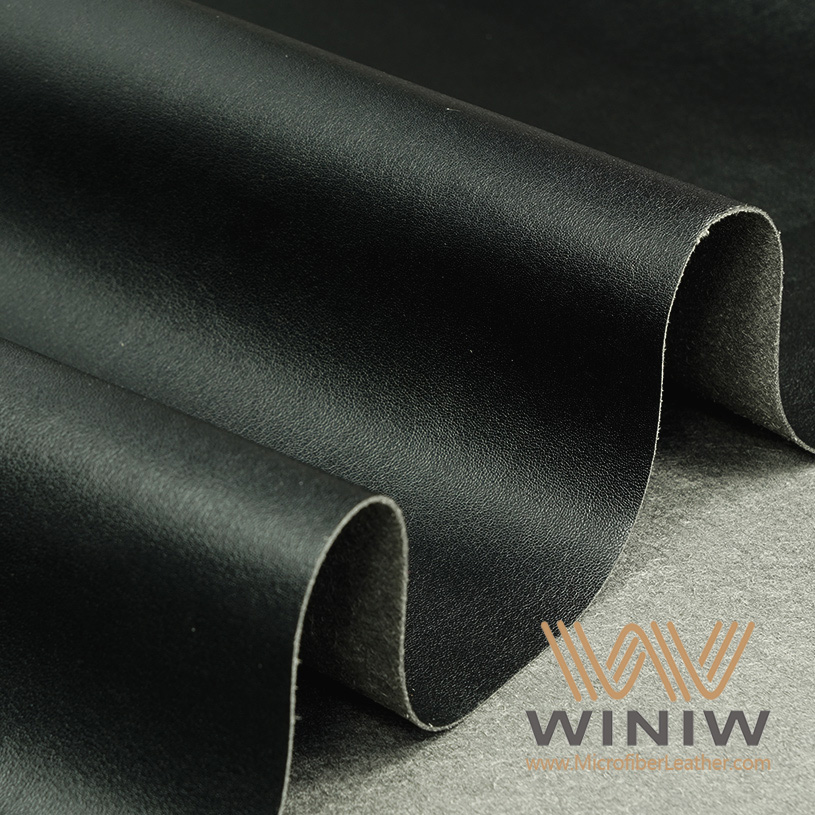

Microfiber leather is a new material emerging with the development of textile technology. The surface layer of the microfiber leather is a thin layer of polyurethane coating, and the bottom layer is a substrate made of ultrafine fiber non-woven fabric impregnated with polyurethane resin. Microfiber leather not only has a structure similar to that of natural leather, but its appearance and touch are similar to those of natural leather, and it is difficult to distinguish the difference between the two in appearance. Therefore, microfiber leather is often used to replace real leather in car seats.

The cost of genuine leather is much higher than that of artificial leather. The most commonly used in automobiles is the first layer of cowhide or the second layer of cowhide. Real leather will basically only appear in mid-to-high-end models of luxury brands; some models that are not very expensive will not use 100% complete leather even if they use leather, but will grind the slag and leather fibers. , Made of reclaimed leather bonded by high-pressure adhesives, or used leather in some frequently contacted parts of the seat, and artificial leather in other parts.

Take a look at the comparison of different leather materials. The microfiber leather is mainly composed of a base layer made of ultrafine fiber non-woven fabric impregnated with polyurethane resin and a dry coating polyurethane surface layer. Because the microfiber non-woven fabric itself has a large porosity, it still retains a certain porosity after being impregnated with polyurethane. Not only can it achieve the leather effect in appearance, but it is also close to leather in structure, and the ride comfort is better than PVC leather, which is equivalent to leather. The dermis is made of raw animal skin, and there is also a porous structure inside, and the dermis material has good air permeability.

As a new type of material, microfiber leather has excellent mechanical properties, color fastness, environmental protection, and cost-effectiveness. Microfiber leather also has strong abrasion resistance and can still maintain high Tensile strength, so it can give the stylist more styling design choices. The application prospect of microfiber leather in car seats is broad. Even with the development of interior design and material technology progress, the price of microfiber leather will drop, which will bring new growth points for its applications, such as door guards. Parts such as visor, sun visor, steering wheel and roof may be applied to microfiber leather materials in a large area.

In comparison, microfiber is better than PVC, and it is the best substitute for real leather. For more product content, please consult WINIW.Website: www.MicrofiberLeather.com

Scan to wechat: