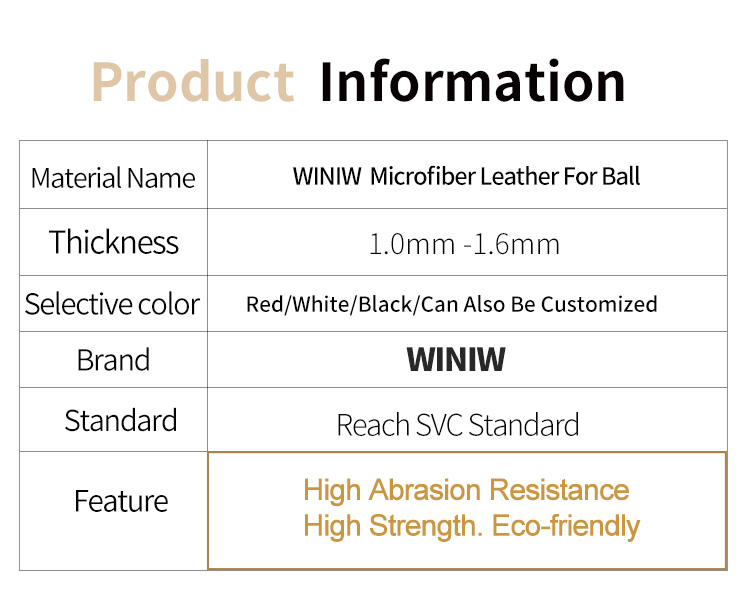

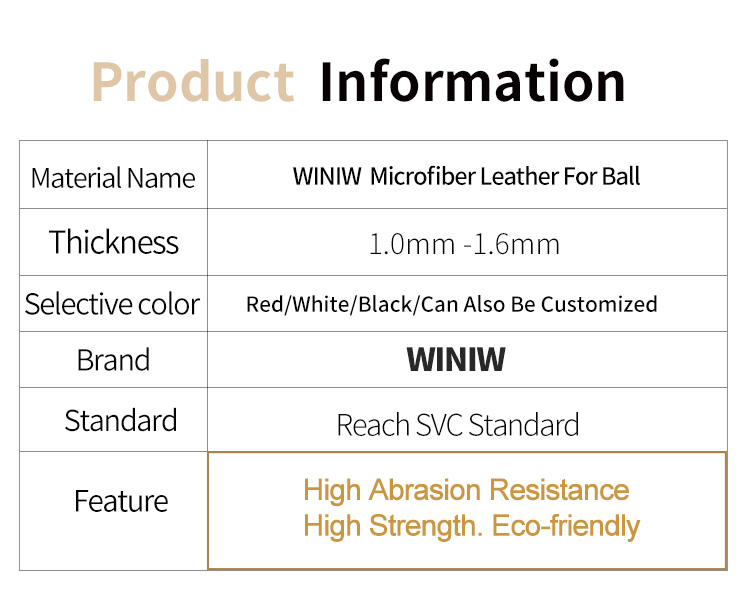

Material Introduction

WINIW, a trusted supplier of high-performance sports materials, proudly presents its Durability-Enhanced Microfiber Artificial Leather for Football Covers—engineered to withstand frequent kicks, impacts, and abrasion while delivering consistent touch and structural integrity for footballs. This product addresses a critical need for sports equipment manufacturers and football brands: a microfiber artificial leather that combines industrial-grade durability with player-centric comfort, ideal for football covers subjected to intensive training, youth use, and outdoor play.

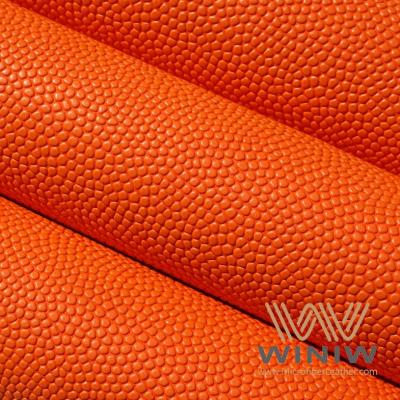

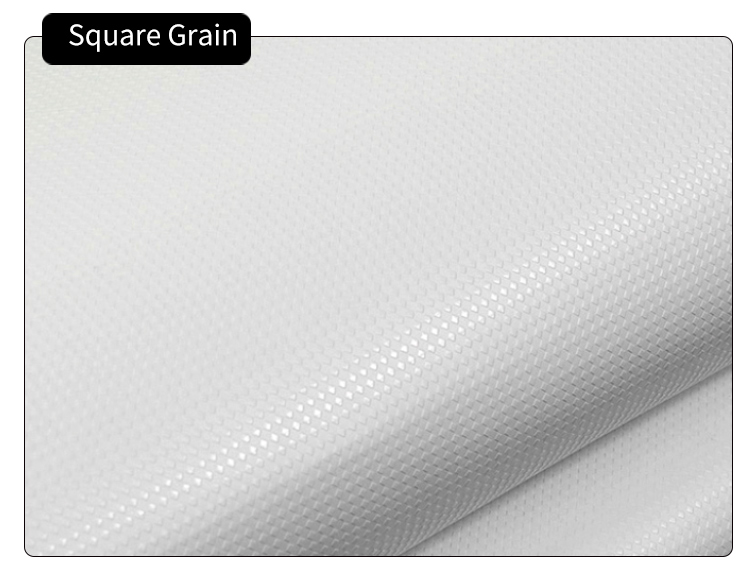

Crafted with WINIW’s advanced reinforced microfiber technology, this artificial leather features a dense, ultra-fine fiber structure infused with durability-enhancing compounds (polyester-nylon blends) that strengthen fiber bonds and resist wear. Unlike ordinary artificial leathers that peel or tear with heavy use, it undergoes a specialized weaving and coating process that achieves a Martindale abrasion resistance of 200,000+ cycles—exceeding standard football material requirements. The material also incorporates a soft, flexible core that mimics natural leather’s feel, paired with a tear-resistant backing that reinforces the ball’s structure against impacts—a key improvement over fragile or rigid alternatives.

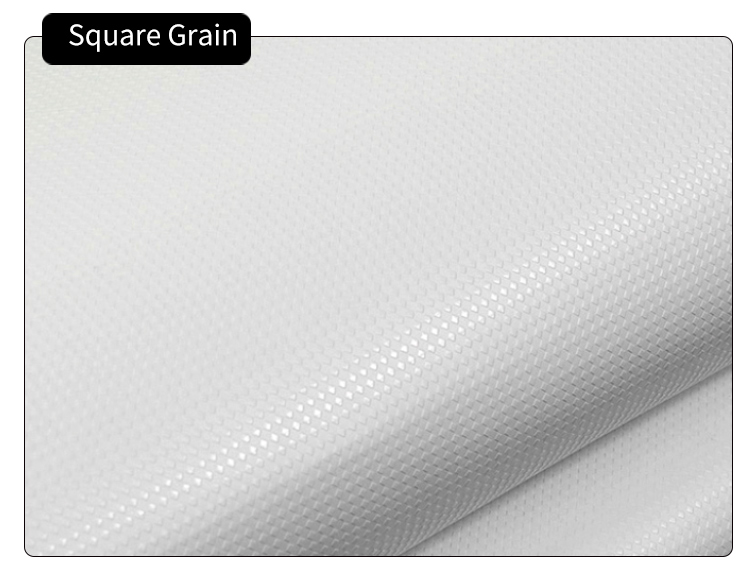

Suitable for training balls, youth footballs, and recreational equipment, it caters to brands focused on long-lasting performance, cost-effectiveness, and compliance with sports safety standards (EN 71, ASTM F963). It accepts custom colorways (vibrant youth tones, team colors), texture variations (soft/supple), and logo printing, aligning with football brand design requirements and market needs. For those seeking a durability-optimized material for football covers, this microfiber artificial leather from WINIW redefines intensive-use performance and value.

Material Feature

This microfiber artificial leather features WINIW’s polyester-nylon blend and reinforced weaving technology, achieving 200,000+ Martindale abrasion resistance. It resists peeling, tearing, and scuffing, outlasting standard materials by 60% in intensive use.

The ultra-fine microfiber texture mimics natural leather’s suppleness, reducing friction on players’ feet and enhancing ball control. It delivers consistent touch across dry and slightly damp surfaces, supporting player confidence in training and games.

At 30% lighter than natural leather, it reduces player fatigue during long sessions. UV resistance prevents fading from outdoor play, while moisture resistance repels light rain and dew—ensuring performance in variable conditions.

Application Scenarios

For training balls, thick durability (1.2mm–1.5mm) withstands daily kicks, drills, and impacts. Abrasion resistance handles grass, turf, and concrete surfaces, while soft touch ensures consistent control during repetitive practice. Cost-effectiveness makes it ideal for team bulk purchases.

In youth footballs, lightweight design (0.8mm–1.0mm) supports skill development without fatigue. Soft touch reduces friction on young players’ feet, and durability withstands rough play. Vibrant custom colors and patterns appeal to younger audiences, enhancing brand engagement.

For school programs, durability and low maintenance are key—resisting frequent use by multiple students and easy cleaning between sessions. UV resistance prevents fading from outdoor playgrounds, and moisture resistance handles light rain during recess games. Customizable sizes (3, 4) adapt to elementary and middle school age groups.

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

Q1: Can this leather be customized to different thicknesses for specific use cases (e.g., thicker for heavy training vs. thinner for youth footballs)?

A1: Yes, we offer thickness customization (0.8mm–1.5mm). Thicker options (1.2mm–1.5mm) provide enhanced durability for heavy training balls, while thinner variants (0.8mm–1.0mm) offer lightweight flexibility for youth and recreational use—all retaining abrasion resistance and soft touch.

Q2: Will the durability properties fade or the material become stiff after long-term use or exposure to sunlight/cleaning?

A2: No, the reinforced microfiber structure and UV-stabilized coating are designed for long-lasting performance. The material retains flexibility and abrasion resistance, avoiding stiffness even after prolonged use and cleaning with sports equipment detergents.

Q3: Can we request custom color matching and pattern printing for brand differentiation (e.g., vibrant youth designs, team stripes)?

A3: Absolutely. We offer precise color customization (vibrant tones, team hues) and pattern printing (stripes, logos, geometric designs) for brand differentiation. The inks are fade-resistant and UV-stable, ensuring long-lasting visual appeal without compromising durability.

Q4: Is it suitable for machine-stitched or thermally bonded footballs, and will it affect production efficiency or quality?

A4: Yes, it is compatible with both production methods. The material’s tear resistance supports machine-stitched panels (no needle damage), while its surface adhesion properties enhance thermally bonded construction (strong, durable bonds). It improves production efficiency with consistent cutability and handling.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com