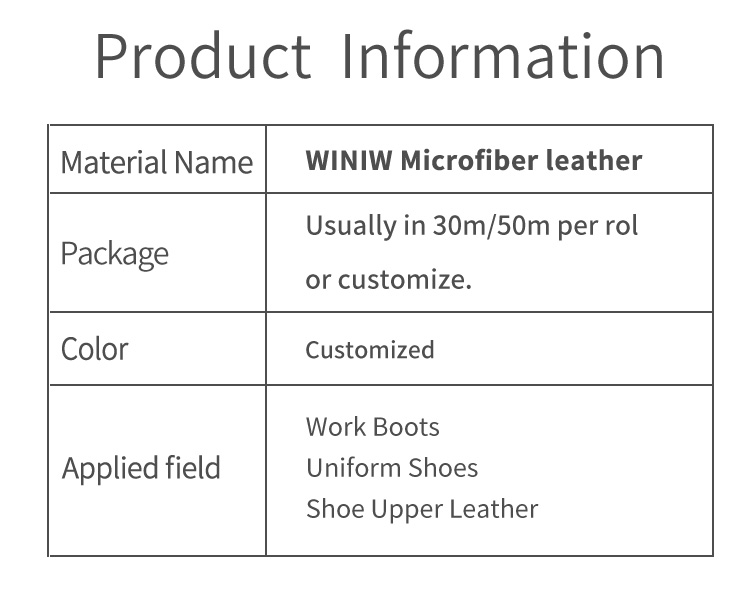

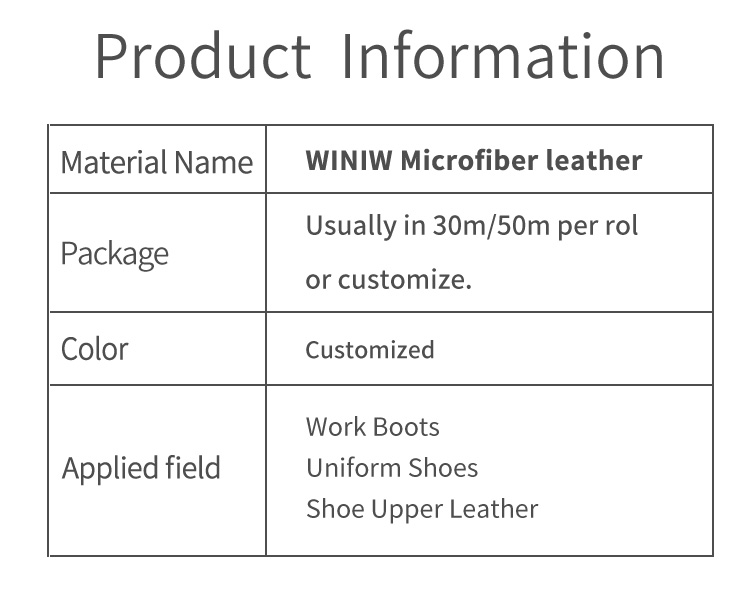

Material Introduction

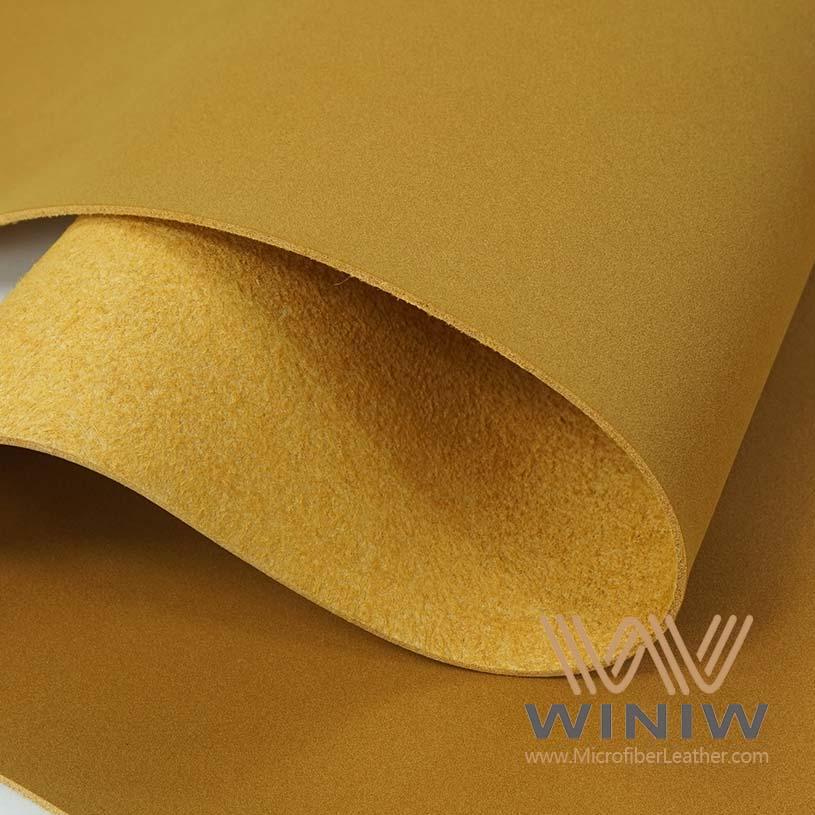

WINIW, an innovator in footwear material technology, presents Easy Processing Artificial Leather for Leather Nubuck Shoe—designed to streamline manufacturing while delivering the premium look and feel of nubuck. This product addresses a key pain point for footwear brands: balancing high-quality nubuck aesthetics with efficient production processes.

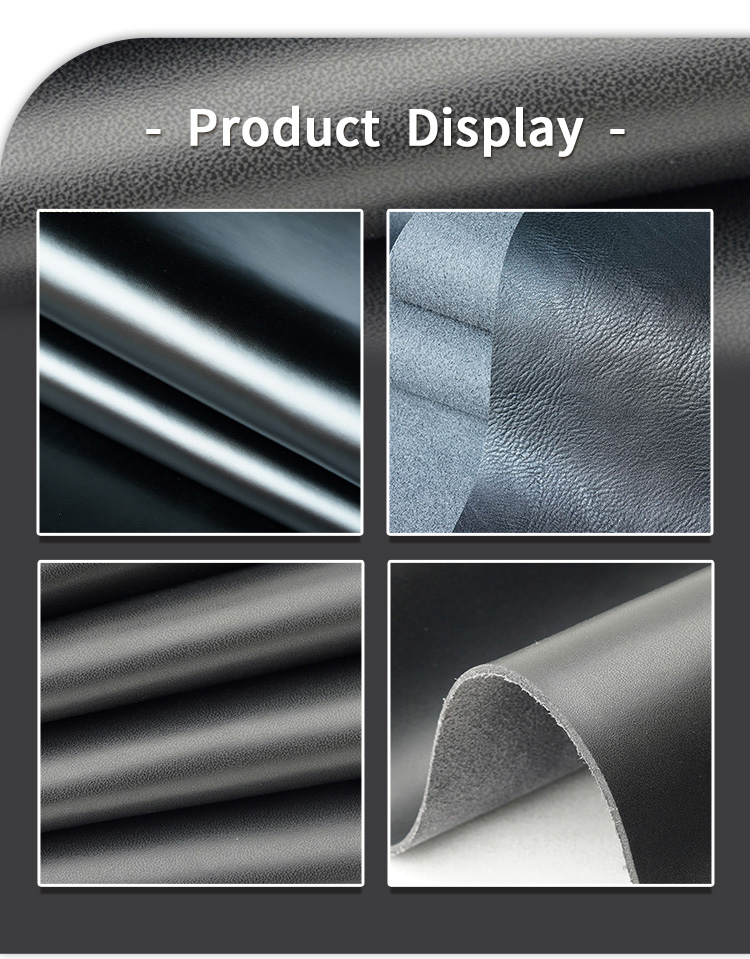

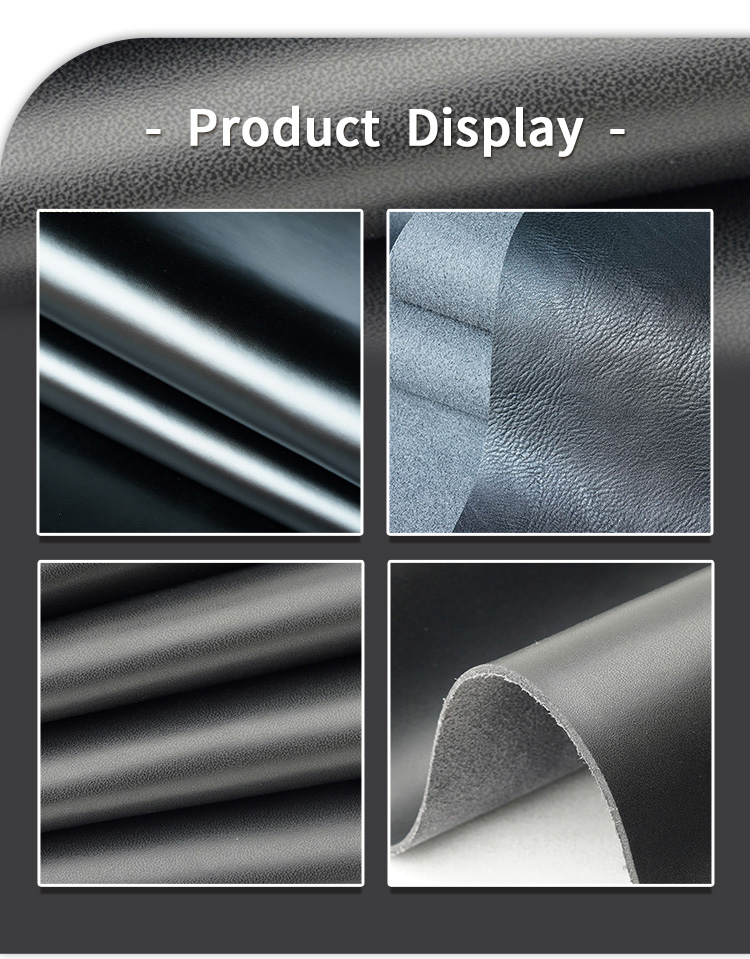

WINIW’s advanced material engineering ensures this artificial leather combines the soft, velvety texture of nubuck with exceptional processability. It simplifies cutting, stitching, shaping, and finishing, reducing production time and costs without compromising on quality. It eliminates the challenges associated with processing genuine nubuck, such as uneven texture or difficult handling.

Suitable for various nubuck shoe styles, it maintains consistent quality across production runs. It bonds well with other shoe components, ensuring structural integrity in the final product. For brands seeking to optimize manufacturing efficiency while delivering premium nubuck-style shoes, this easy-processing artificial leather from WINIW offers a practical, high-value solution that meets both production and market demands.

Material Feature

This artificial leather is engineered for easy processing. It cuts smoothly, stitches cleanly, and shapes effortlessly, streamlining production workflows. It reduces manufacturing time and waste, supporting efficient, cost-effective shoe production.

It delivers the genuine nubuck look and feel that consumers desire. The soft, velvety nap and natural appearance mirror high-quality nubuck, adding premium appeal to the final shoe. It meets market expectations for nubuck aesthetics without the processing challenges.

It maintains uniform thickness, texture, and color across batches. This consistency ensures every shoe meets the same high standard, avoiding variations that can affect product quality. It supports reliable, consistent production for footwear brands.

Application Scenarios

In mass-produced casual shoes, this leather’s easy processing supports efficient manufacturing. It cuts and stitches uniformly, reducing waste and speeding up production. Its nubuck texture adds premium appeal, making casual shoes accessible to a wider market.

For mid-range dress shoes, it balances quality and cost-effectiveness. It delivers nubuck’s luxury look without the high processing costs of genuine nubuck. It maintains consistent quality, ensuring dress shoes meet consumer standards for appearance and durability.

In women’s fashion boots, it supports creative designs with easy processing. It shapes effortlessly into various boot styles, from ankle to knee-high. Its nubuck texture adds elegance, while durability ensures the boots withstand regular wear and fashion trends.

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

No, it does not require special equipment. It works with standard shoe manufacturing tools for cutting, stitching, and shaping. It integrates seamlessly into existing production lines, avoiding the need for costly upgrades.

Yes, it bonds securely with common shoe materials like rubber, foam, or other leathers. It adheres well to adhesives, creating strong, durable connections that enhance the shoe’s overall structure. It supports versatile design combinations.

Absolutely. Its consistent quality and easy processing make it ideal for mass production. It reduces production time per unit, supports high-volume manufacturing, and ensures every shoe meets the same quality standard.

No, processing does not compromise the nubuck texture. It retains its soft, velvety nap through cutting, stitching, and finishing. The manufacturing process preserves the material’s aesthetic appeal, delivering consistent nubuck-style shoes.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com