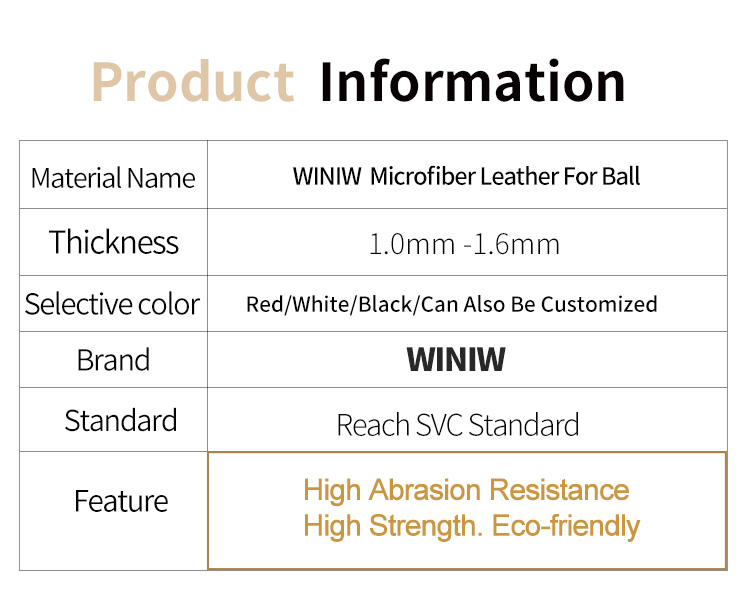

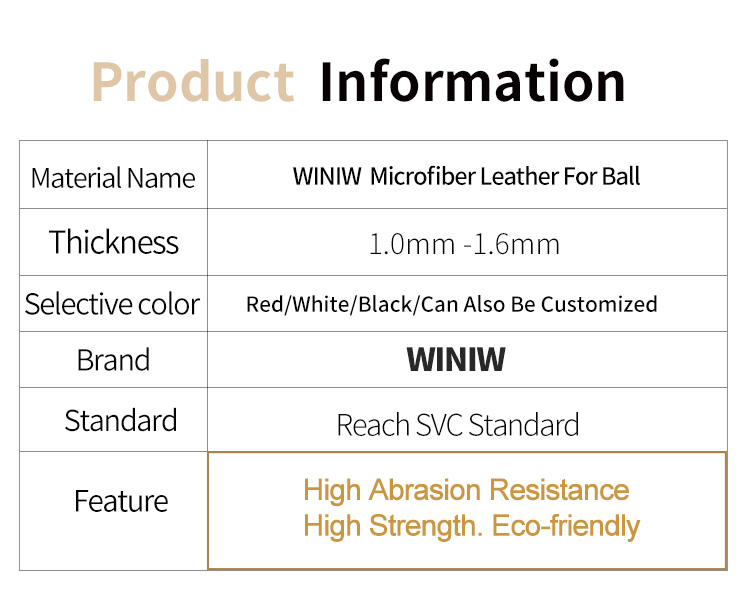

Material Introduction

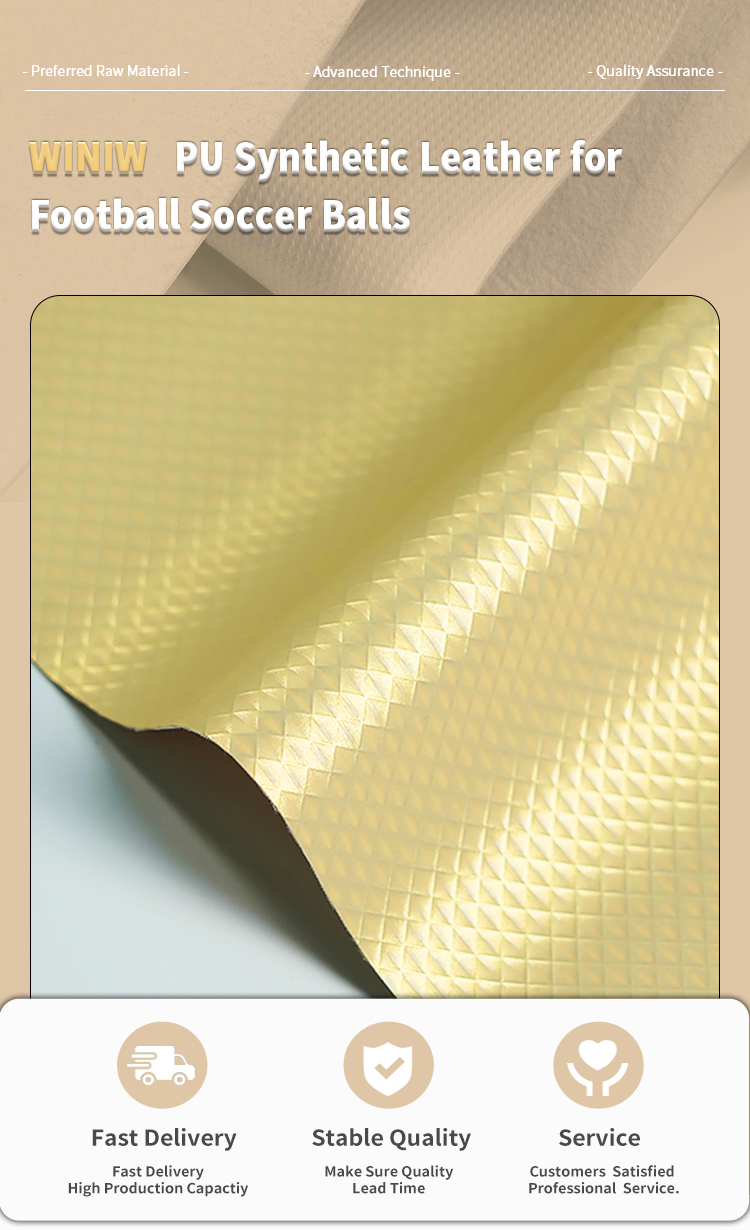

WINIW is a leading supplier of high-performance sports equipment materials, and its Easy to Sew Leather Material for Football Pu Material is a game-changer for football manufacturing. This PU-based leather is specifically engineered to address the key challenge of sewing in football production, combining excellent sewability with the durability required for intense gameplay.

As a brand trusted by global sports goods manufacturers, WINIW optimizes the material’s texture and flexibility to ensure smooth stitching operations. Unlike ordinary PU leathers that may fray or break during sewing, this material maintains structural integrity while allowing precise needle penetration. It also retains the tactile feel and bounce compatibility essential for footballs, meeting the demands of both amateur and professional use.

Crafted under strict quality control, the material offers consistent performance across every roll, ensuring uniform sewing results for mass-produced footballs. Whether for training balls, match balls, or custom-designed footballs, WINIW’s Easy to Sew Leather Material for Football Pu Material balances functionality, durability, and processability, making it a top choice for football manufacturers worldwide.

Material Feature

-

Advantage 1: Superior Sewability, Smooth Manufacturing Process

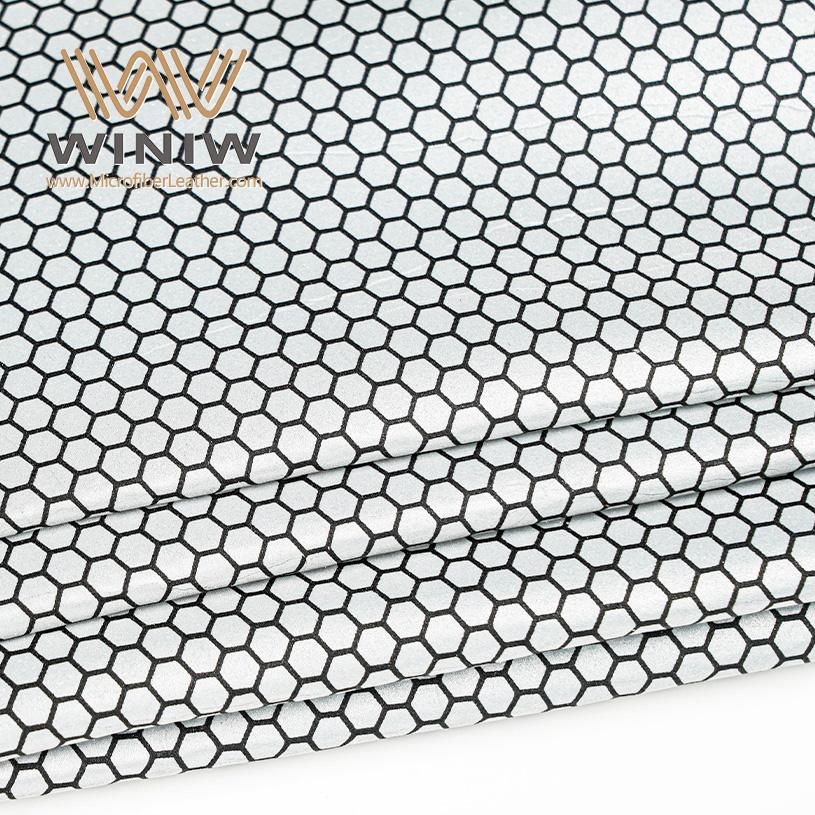

The material is optimized for sewing with balanced flexibility and anti-fray properties. It allows needles to penetrate smoothly without causing thread breakage or edge fraying, ensuring precise stitching of football panels. This reduces manufacturing errors and improves production efficiency, saving time and labor costs for manufacturers.

Advantage 2: Excellent Wear Resistance, Long Service Life

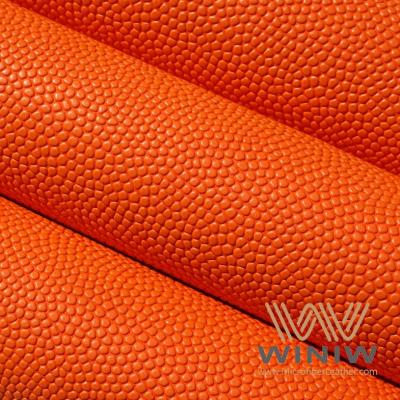

Crafted from high-quality PU, it exhibits strong resistance to wear and impact. It can withstand repeated kicks, collisions, and friction on various surfaces—grass, turf, or concrete—without scratches, cracks, or shape deformation. Footballs made from this material maintain performance and appearance for extended use.

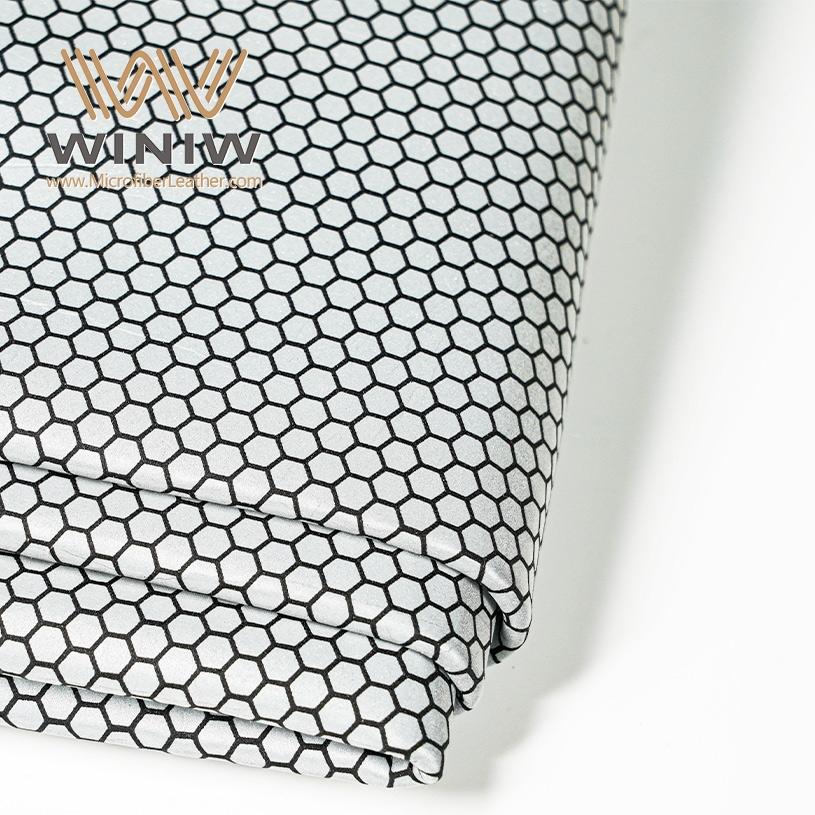

Advantage 3: Optimal Tactile Feel, Professional Performance

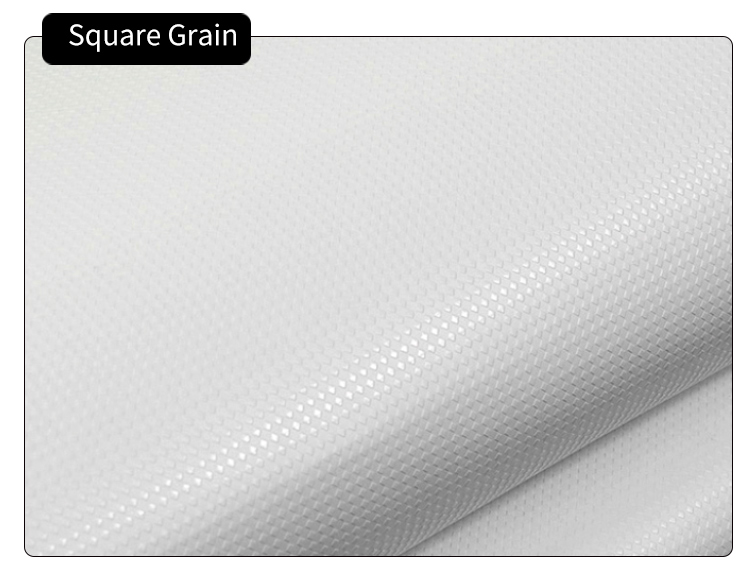

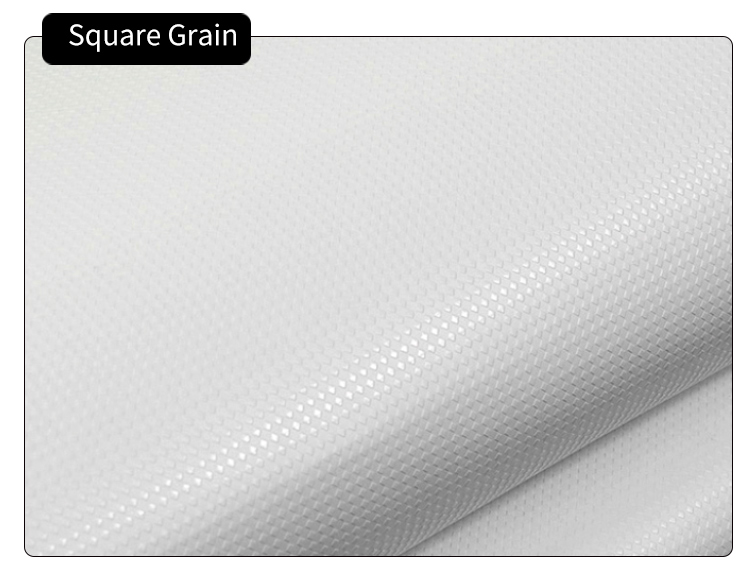

It features a fine, non-slip surface texture that provides excellent grip for players, even in sweaty or wet conditions. The material’s density is calibrated to ensure consistent bounce, meeting the performance requirements of training and match footballs. It delivers a professional-level tactile experience that players prefer.

Application Scenarios

-

Scenario 1: Professional Match Footballs

Professional matches demand footballs with precise stitching and stable performance. This material’s sewability ensures neat, strong stitching of panels, preventing deformation during intense matches. Its wear resistance and consistent bounce meet official match standards, supporting professional gameplay.

Scenario 2: Amateur Training Footballs

Amateur training involves frequent use on various surfaces. The material’s wear resistance withstands repeated kicks and friction on turf or concrete. Its easy sewability allows cost-effective mass production, providing durable training balls for schools, clubs, and community teams.

Scenario 3: Customized Themed Footballs

Custom footballs for events or brands often have unique panel designs and colors. This material supports color and texture customization, matching themed requirements. Its sewability ensures complex custom panel stitching is smooth, creating high-quality, personalized footballs for promotions or souvenirs.

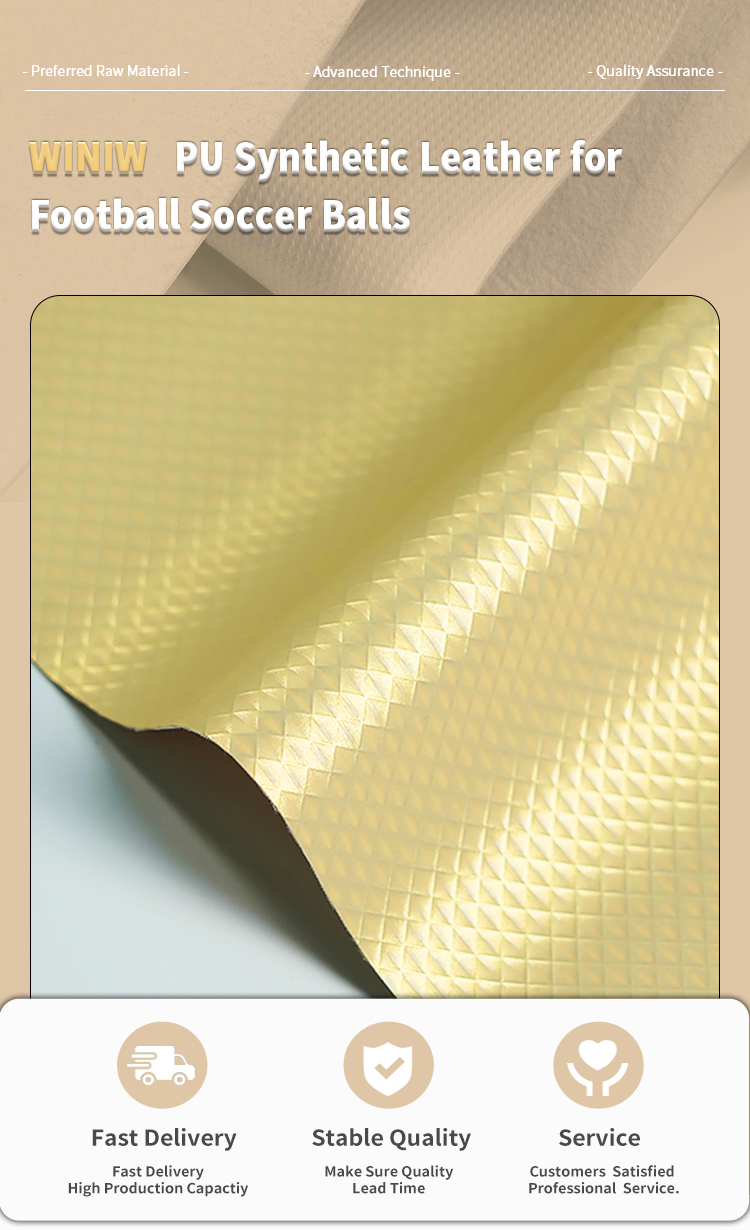

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

Q1: Can this easy-to-sew material be customized with different surface textures for footballs?

A1: Core keyword: "surface texture customization". Yes, it can. We offer various surface texture options, from fine grain to subtle embossing. The customized texture retains the material’s sewability, ensuring smooth manufacturing while meeting your design needs for grip or aesthetics.

Q2: Is this material suitable for sewing footballs with complex panel designs?

A2: Core keyword: "complex panel sewing suitability". Yes, it is. Its excellent flexibility allows it to fit various complex panel shapes and stitching paths. It maintains stability during the sewing of irregular or multi-panel designs, ensuring consistent stitching quality without fraying.

Q3: Will the material’s sewability decrease after dyeing into dark or bright colors?

A3: Core keyword: "dyeing and sewability". No, it won’t. Our dyeing process is compatible with the material’s structure, whether dyed dark or bright. The color penetrates evenly without hardening the material, keeping its sewability and flexibility intact.

Q4: Can this material be used for both hand-sewn and machine-sewn footballs?

A4: Core keyword: "hand and machine sewing compatibility". Yes, it can. It is designed to adapt to both hand and machine sewing. For machine sewing, it resists needle friction; for hand sewing, it offers good needle control. It ensures consistent quality across different sewing methods.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com