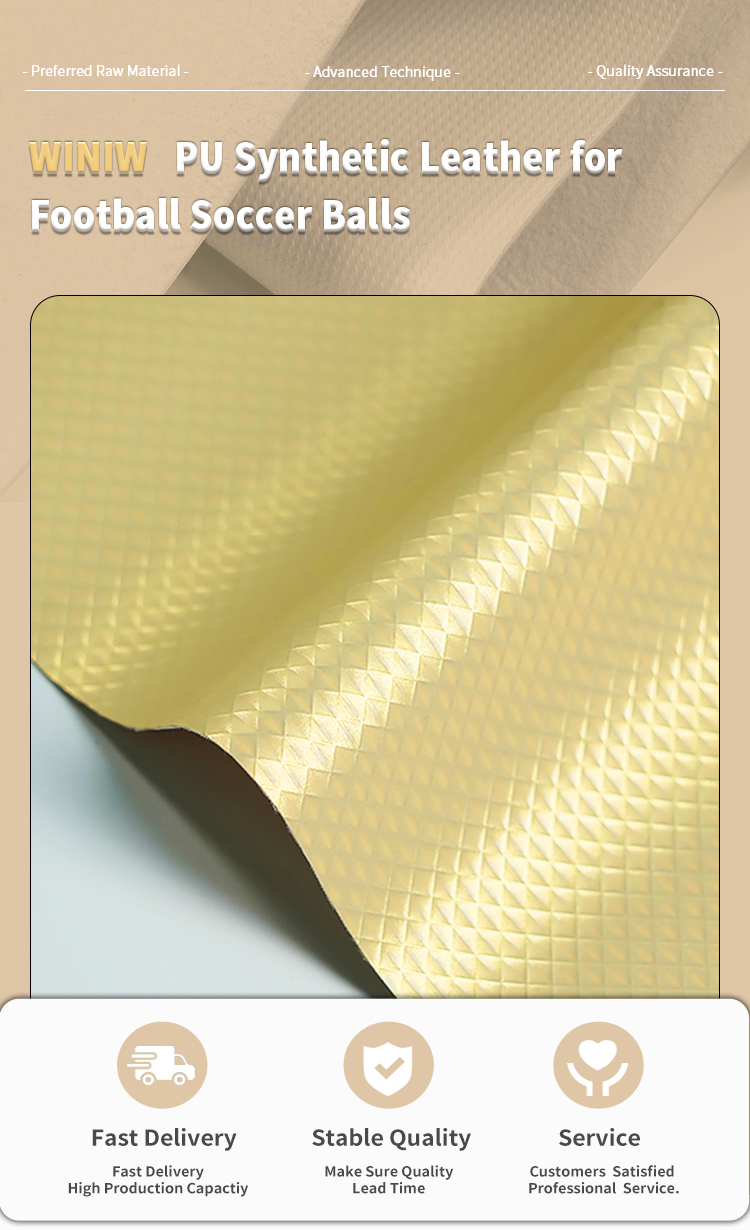

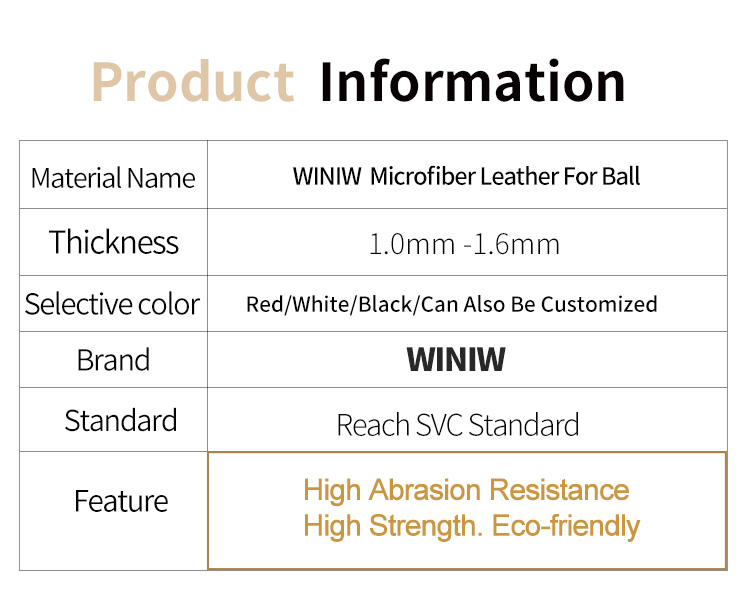

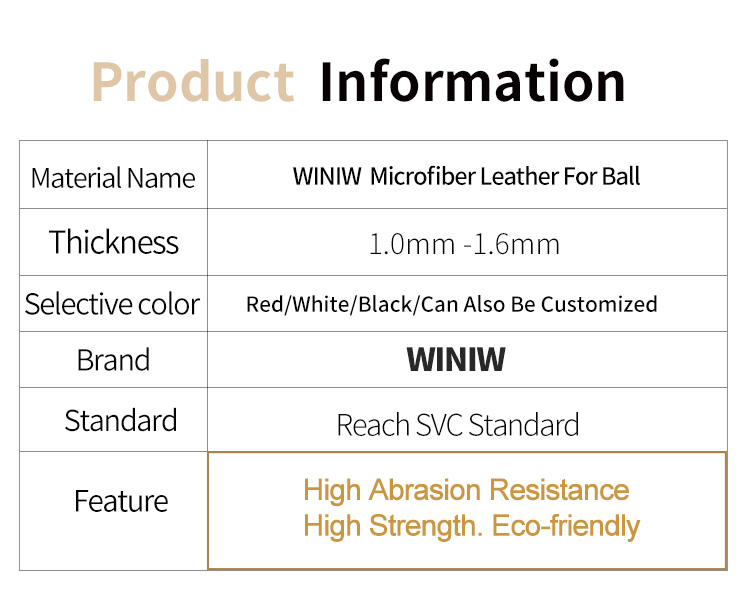

Material Introduction

WINIW understands that manufacturing efficiency is a key priority for football brands, and its Easy to Sew Synthetic Leather for Football is designed to streamline production without sacrificing quality. This product addresses a common pain point in football manufacturing: synthetic leathers that resist stitching, cause thread breakage, or require specialized equipment to work with.

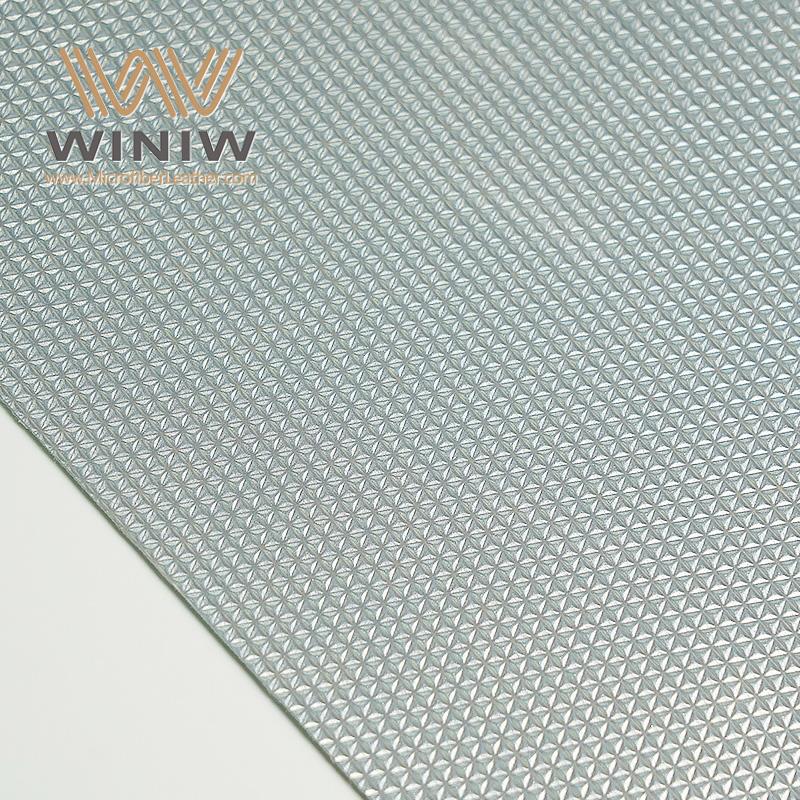

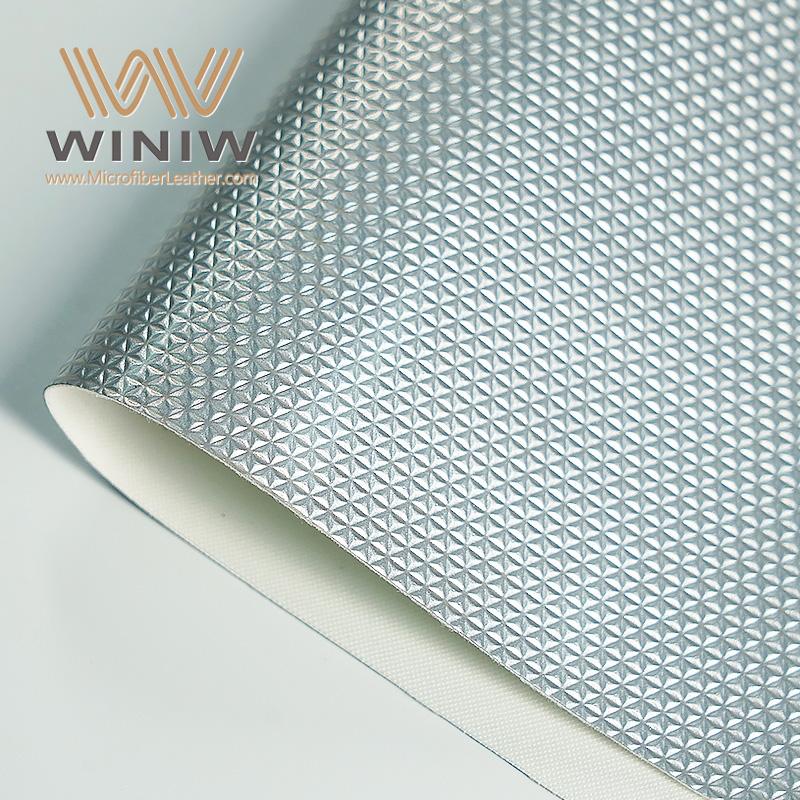

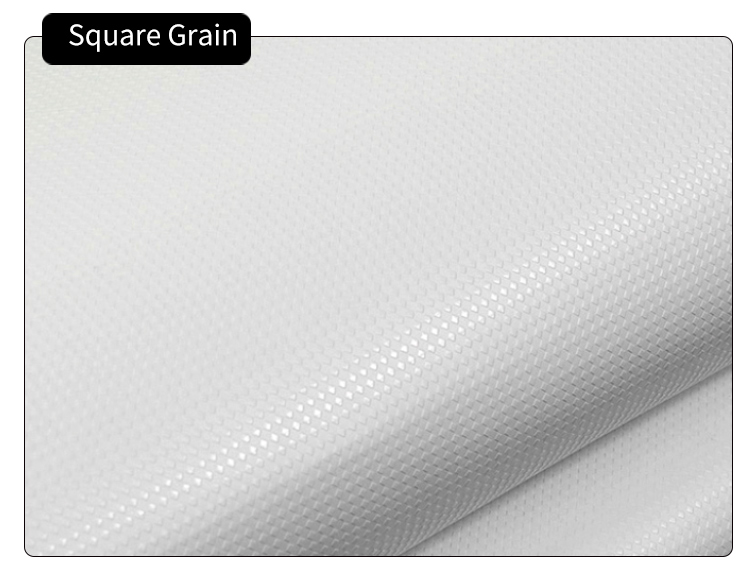

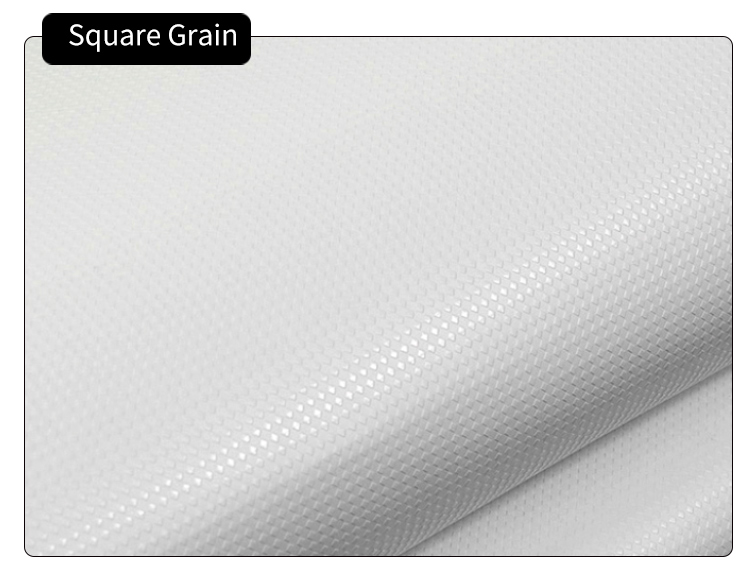

Crafted with a smooth, flexible base and optimized thickness, WINIW’s Easy to Sew Synthetic Leather glides under sewing machines, accommodating both manual and automated stitching processes with ease. It eliminates the need for excessive adjustments or slow production speeds, allowing manufacturers to meet tight deadlines while maintaining consistent stitching quality.

Beyond sewability, the leather retains the durability and performance required for footballs—it resists wear, maintains shape, and offers a reliable feel for players. Whether producing training balls, match balls, or custom designs, brands benefit from a material that balances production efficiency with on-field performance. With this product, WINIW continues to support football manufacturers by delivering solutions that make the production process smoother, faster, and more cost-effective, without compromising the final product’s quality.

Material Feature

The leather’s flexible, stable texture ensures it sews easily with standard equipment—no thread breakage, needle jams, or frequent adjustments. This cuts down on production time, reduces waste from sewing errors, and lets manufacturers meet high order volumes without sacrificing quality.

With uniform thickness across the material, every stitch is even and secure. This eliminates weak spots in the football’s construction, ensuring the panels stay attached even during intense play, which enhances the football’s longevity and reliability.

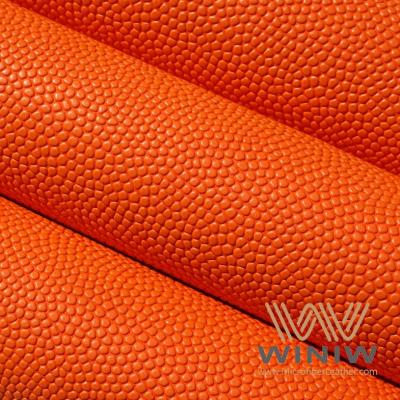

While easy to sew, the leather is tough enough to withstand football use—resisting scuffs, tears, and shape loss. It ensures the final football performs well on the field, so manufacturers don’t have to choose between production ease and on-field durability.

Application Scenarios

Perfect for brands mass-producing training footballs. Its easy-sew design works with automated assembly lines, allowing fast, high-volume production without sewing errors. The durable build handles daily training use, making it a cost-effective choice for bulk orders.

Ideal for creating custom-branded footballs (with team logos, event names, or unique designs). Its compatibility with decorative stitching lets you add custom details easily, and the consistent sewability ensures every branded football meets your quality standards—great for promotions, events, or team merchandise.

Suitable for youth-sized footballs. The easy-sew material allows for precise stitching of smaller panels, ensuring the football is lightweight and safe for young players. Its durability resists the rough handling common in youth games, keeping the football in good shape for seasons.

Works well for specialty footballs, such as mini footballs (for keychains, souvenirs) or indoor futsal balls. Its adaptability to different sizes and stitching needs makes it easy to create these niche products, and the material’s durability ensures even small or specialized footballs hold up to use.

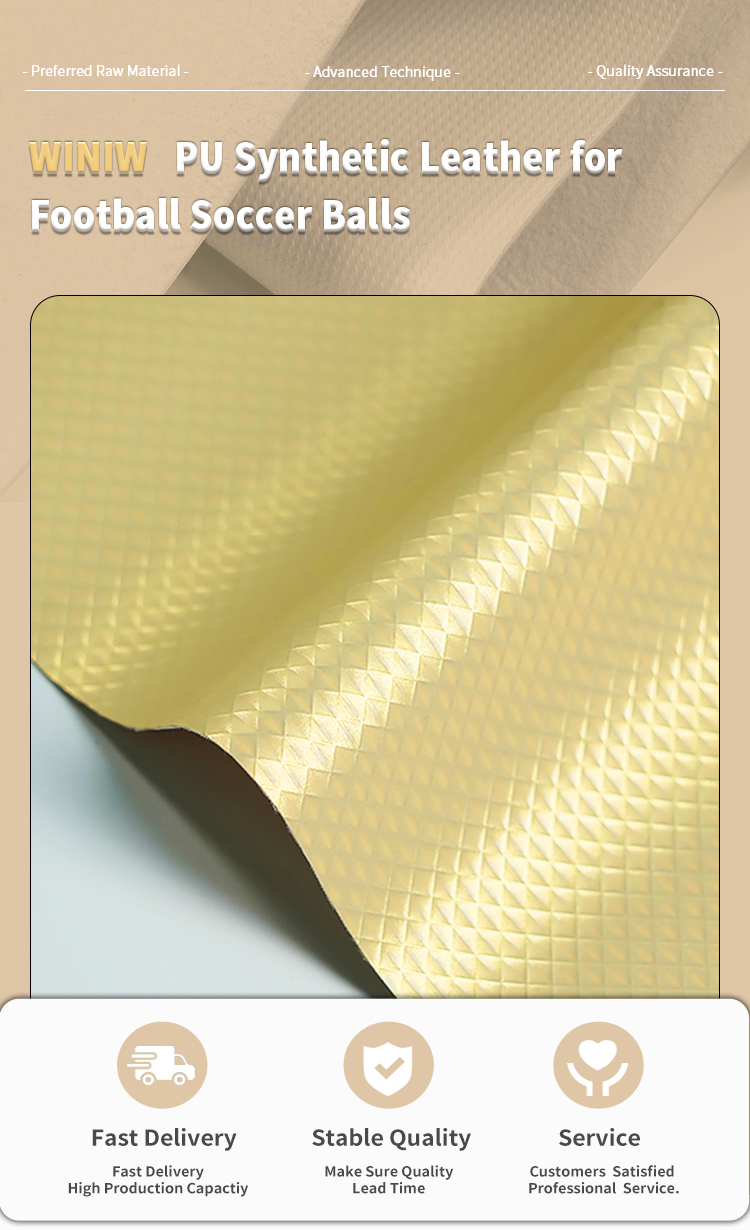

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

Yes, it’s compatible with both automated and manual sewing systems. Its smooth texture and consistent thickness work well with the speed of automated machines, while its flexibility makes manual stitching easier for small-batch or custom football production.

No, the material is designed to resist fraying. Its edges stay neat after cutting and sewing, preventing unravelling that can compromise the football’s panels. This ensures the final product maintains structural integrity over time.

Absolutely. The leather’s easy-sew nature supports decorative stitching, logos, or custom panel designs. These additions don’t weaken the material or disrupt its durability, allowing you to create unique, branded footballs without performance trade-offs.

Yes, its versatility makes it ideal for all football sizes. It adapts to the varying panel shapes and stitching requirements of youth, adult, or mini footballs, ensuring consistent sewability and quality across your entire product range.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com