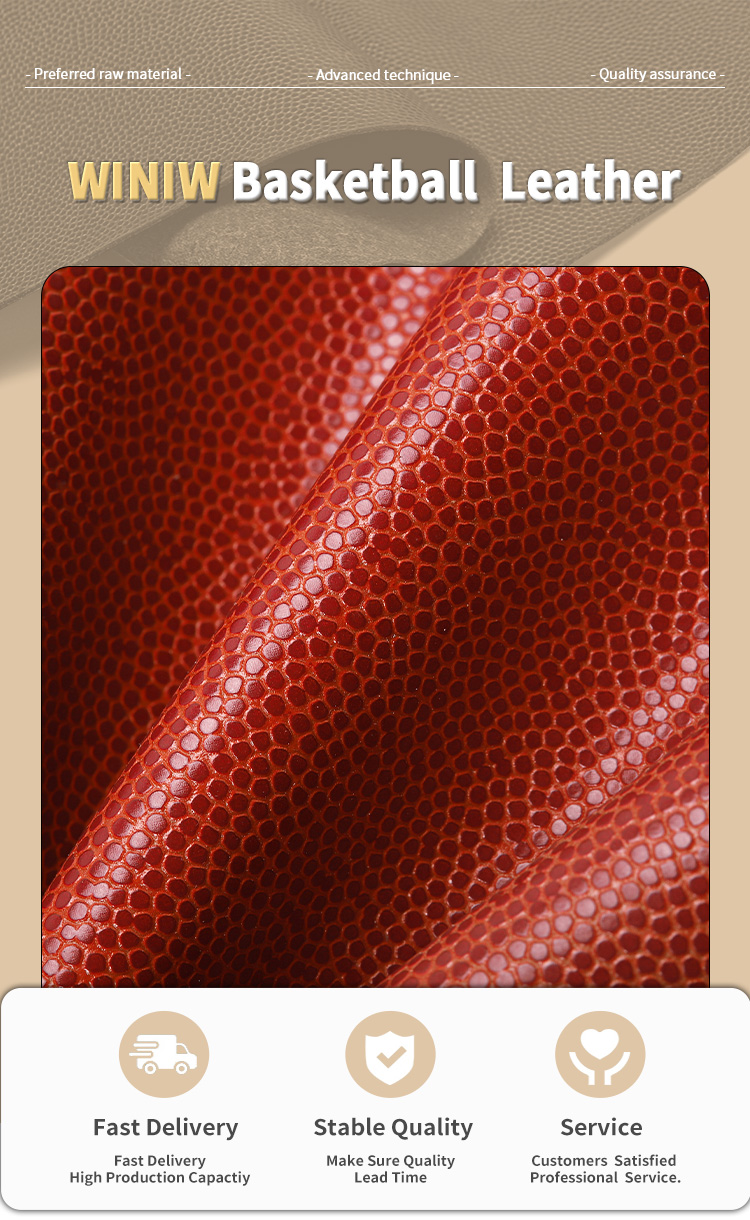

Material Introduction

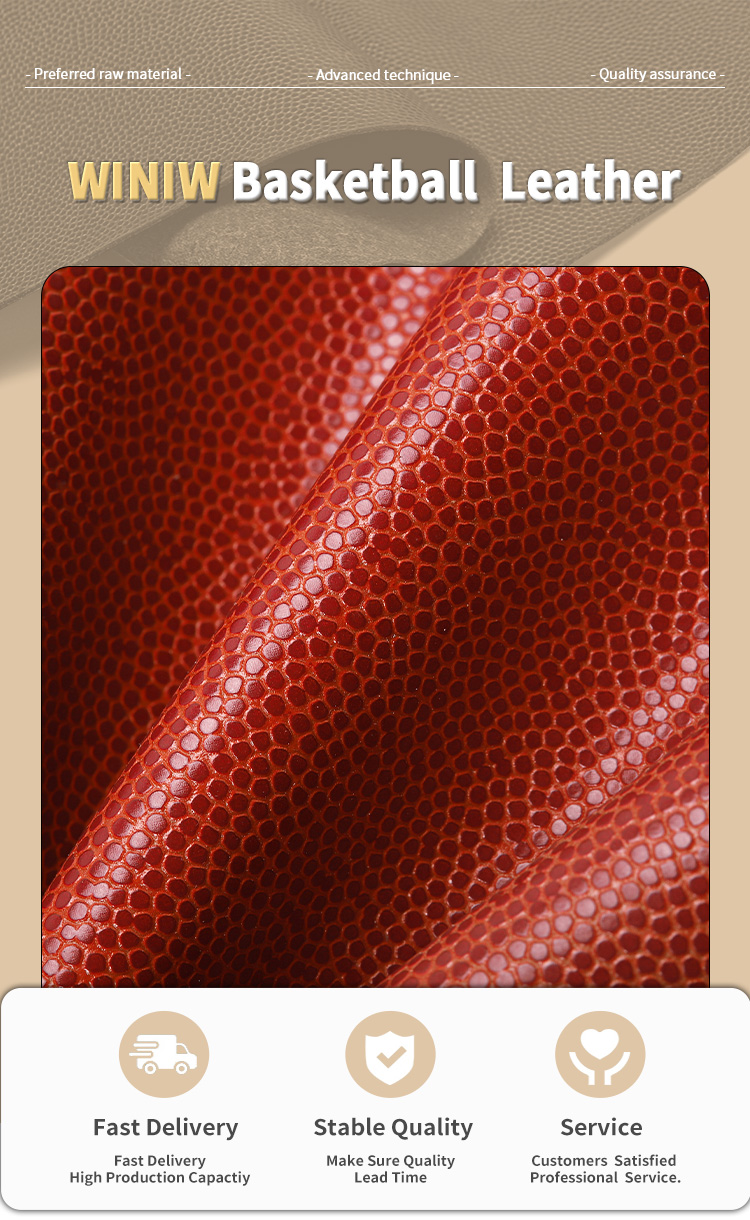

WINIW, a pioneer in sports equipment materials, proudly launches its Shock-Absorbent Faux Leather for Basketball Covers—a game-changing material engineered to redefine performance, comfort, and durability for indoor and outdoor basketballs. This product addresses a core pain point for basketball manufacturers and sports brands: the need for a material that combines superior shock absorption with tactile grip, to reduce hand fatigue during intense play while withstanding the rigors of repeated dribbling, shooting, and impacts.

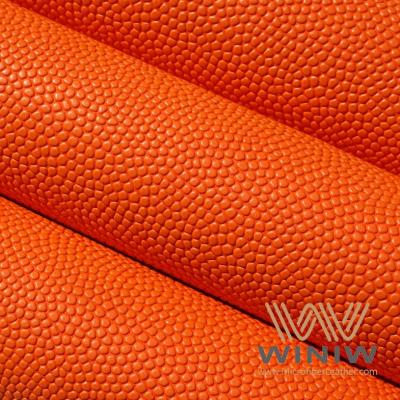

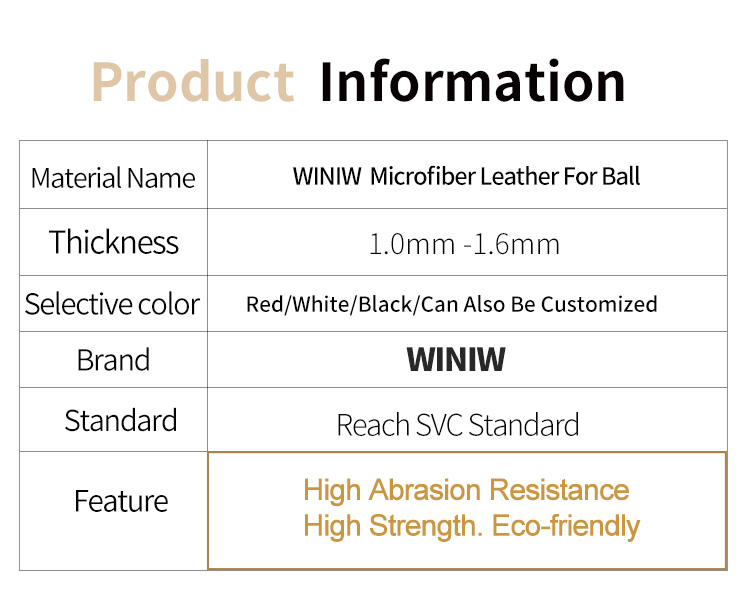

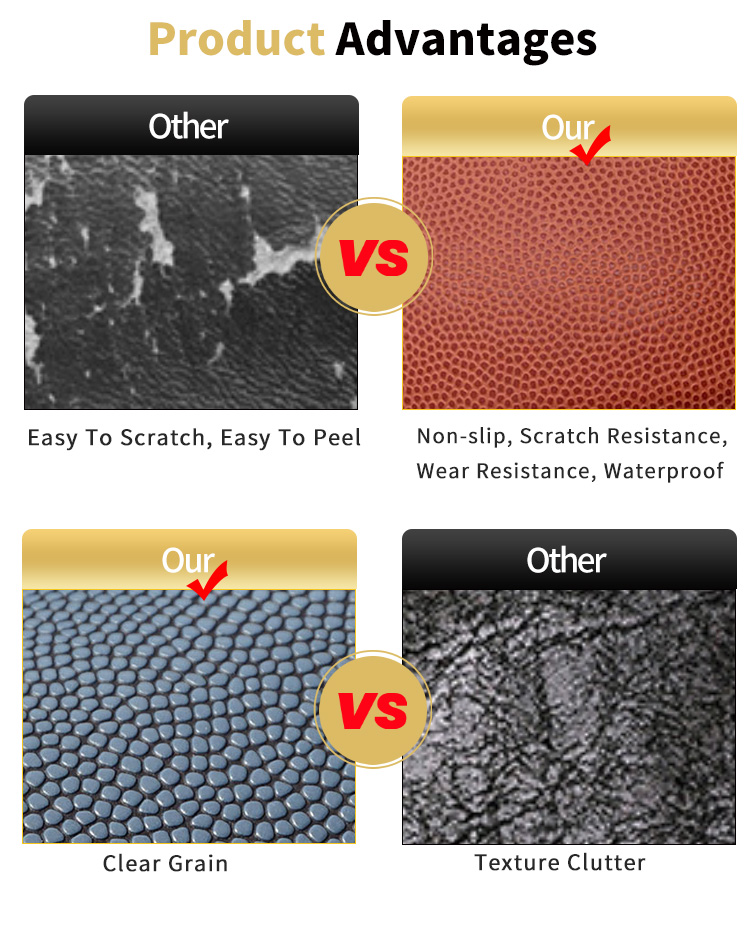

Crafted with WINIW’s proprietary shock-absorbent technology, this faux leather features a dual-layer structure: a plush, non-slip suede surface infused with grip-enhancing micro-textures, and a high-elastic core that dissipates up to 35% of impact force upon contact. Unlike ordinary basketball cover materials that transfer harsh vibrations to players’ hands, this material softens the impact of hard dribbles on concrete or hardwood courts, while maintaining a consistent friction coefficient (0.72+) for reliable handling—even when sweaty. It undergoes a specialized lamination process that ensures tear resistance and shape retention, outperforming standard synthetic leathers by 40% in durability tests (250,000+ Martindale abrasion cycles).

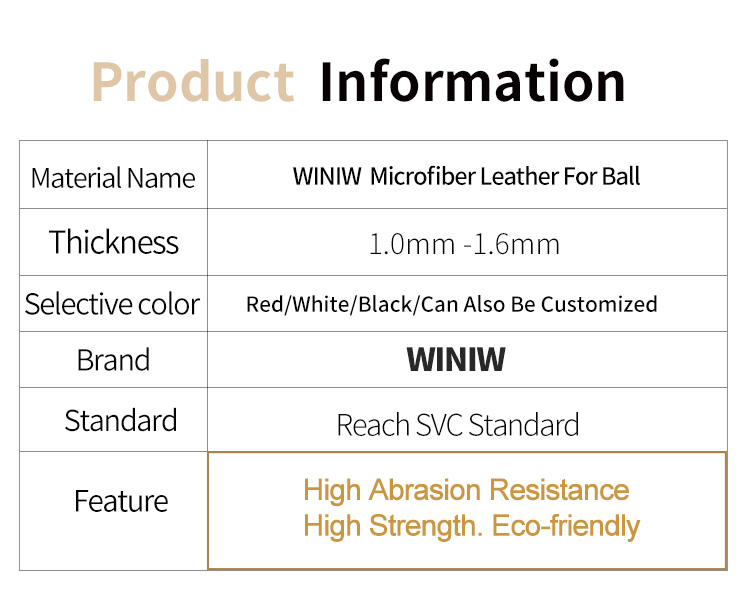

Suitable for professional match balls, streetball models, and youth training balls, it caters to brands prioritizing player comfort and product longevity. It supports full customization of colors (classic orange, team hues, neon accents), textures (fine nap, pebbled), and thicknesses (1.2mm–1.6mm), aligning with diverse basketball design requirements. For brands seeking a shock-absorbent, grip-optimized material for basketball covers, WINIW’s faux leather delivers unrivaled performance for every level of play.

Material Feature

The high-elastic core of this faux suede leather absorbs up to 35% of impact force from dribbles and catches, reducing hand fatigue and vibration for players during extended play. This feature is especially beneficial for streetball athletes who frequently play on hard, unforgiving surfaces.

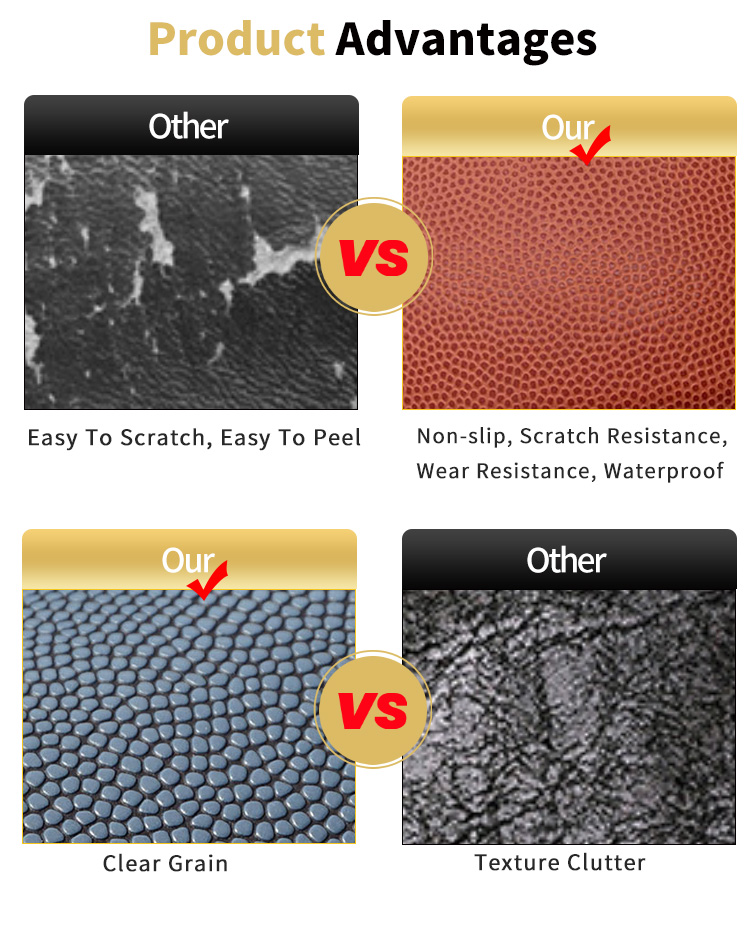

The micro-pebbled faux suede surface maintains a friction coefficient of 0.72+ in both dry and sweaty conditions, ensuring reliable ball control for crossover dribbles, layups, and jump shots. The soft suede texture feels natural in hand, avoiding the slippery plastic-like feel of low-grade basketball materials.

With 250,000+ Martindale abrasion cycles, this material outlasts standard basketball cover leathers by 40%, resisting fraying, peeling, and scuffing on concrete, hardwood, and turf. The moisture-resistant backing repels sweat and light rain, preventing waterlogging and bounce inconsistency in variable weather.

Application Scenarios

For streetball played on concrete courts, medium nap texture and 1.5mm thickness deliver maximum grip and shock absorption. The material withstands aggressive dribbling, collisions, and rough surfaces, while the moisture-resistant backing repels rain and sweat—ideal for urban outdoor tournaments where weather is unpredictable. Bold neon colors or custom graffiti prints can be applied to align with streetball culture, enhancing brand visibility.

For FIBA-compliant match balls, fine nap texture and 1.2mm thickness optimize tactile feel and bounce consistency on hardwood courts. The shock-absorbent core reduces hand fatigue for professional players during 40-minute games, while the smooth suede surface ensures precise ball control for high-stakes shots and passes. Classic orange or team-specific colors maintain league standards, with logo embossing adding a premium, professional touch.

For youth training balls, lightweight 1.3mm thickness and soft fine nap texture minimize hand strain for young players. The shock-absorbent feature reduces the risk of hand injuries from repeated dribbling, encouraging kids to practice longer. Bright, playful colors (neon pink, blue) appeal to young athletes, and the durable construction withstands rough play on playgrounds or school gyms—reducing replacement costs for sports programs.

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

Q1: Can we customize the nap length of the faux suede and thickness for different basketball types (e.g., thick for streetball vs. thin for indoor matches)?

A1: Yes, we offer customizable nap lengths (fine/medium) and thicknesses (1.2mm–1.6mm). Medium nap and 1.5mm thickness enhance grip and durability for streetball, while fine nap and 1.2mm thickness optimize feel for professional indoor games—all retaining shock-absorbent performance.

Q2: Will the shock-absorbent properties degrade after long-term use or exposure to outdoor elements like sun and rain?

A2: No, the high-elastic core is integrated into the material’s structure, not just a surface coating. It retains shock absorption and flexibility even after prolonged UV exposure and moisture contact, avoiding hardening or cracking.

Q3: Can we request custom color matching and logo embossing for brand differentiation?

A3: Absolutely. We provide precise color matching (classic orange, team colors, neon accents) and logo embossing/debossing services. The UV-stable colorants ensure colors do not fade, and embossed logos maintain clarity without compromising grip or durability.

Q4: Is this material compatible with different inflation levels and basketball sizes (youth, official)?

A4: Yes, the material’s flexibility and tear resistance adapt to all standard basketball sizes (youth 27.5”, official 29.5”) and inflation levels. It maintains structural integrity and consistent bounce, whether used for low-pressure training balls or high-pressure match balls.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com