Material Introduction

WINIW, a leading provider of high-performance synthetic leather, proudly presents its Static-Dissipative Synthetic Suede Leather for Electronic Assembly Gloves—a specialized material engineered to safeguard precision electronic components while ensuring optimal dexterity for assembly line workers. This product addresses a critical pain point for electronics manufacturing brands: the need for a glove material that eliminates static discharge risks without compromising tactile sensitivity for handling microchips, circuit boards, and delicate parts.

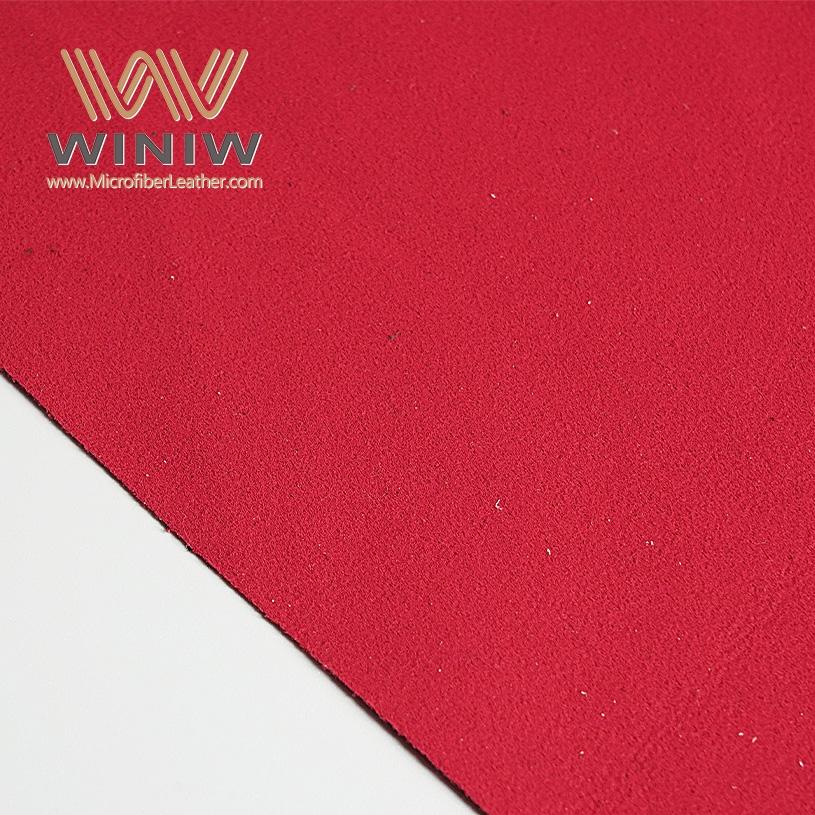

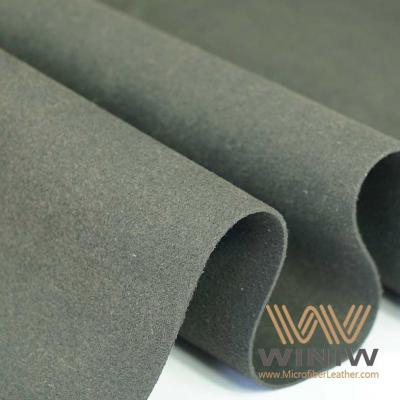

Crafted with WINIW’s proprietary anti-static technology, this synthetic suede leather features a conductive polymer-infused surface that dissipates static electricity at a rate of 10⁶–10⁹ ohms, complying with ESDS (Electrostatic Discharge Sensitive) component handling standards. Unlike ordinary glove materials that generate static and damage sensitive electronics, this synthetic suede prevents charge buildup, even in low-humidity factory environments. Its ultra-fine nap surface delivers a soft, non-abrasive touch that avoids scratching component surfaces, paired with a lightweight, flexible core that ensures unrestricted finger movement for precise assembly tasks. The material is also treated with a dust-repellent coating, keeping particles off gloves and away from cleanroom work areas. With 150,000+ Martindale abrasion cycles, it outperforms standard anti-static materials by 30% in durability, making it ideal for high-volume electronic assembly lines.

Suitable for cleanroom assembly gloves, precision handling mitts, and ESD-safe work gloves, it supports customization of colors (white, light blue, gray), thicknesses (0.8mm–1.0mm), and anti-static ratings, aligning with electronics industry cleanroom standards. For brands seeking a static-dissipative, dexterity-focused material for electronic assembly gloves, WINIW’s synthetic suede leather sets a new benchmark for safety and performance.

Material Feature

Infused with conductive polymers, this synthetic suede leather dissipates static electricity at a controlled rate, meeting global ESDS standards for handling sensitive electronic components. It eliminates static discharge risks, protecting microchips, circuit boards, and precision parts from irreversible damage.

The ultra-fine nap surface provides a soft, non-abrasive touch that avoids scratching delicate component surfaces. Its lightweight, flexible design ensures unrestricted finger movement, enabling precise handling of tiny parts for high-precision assembly tasks.

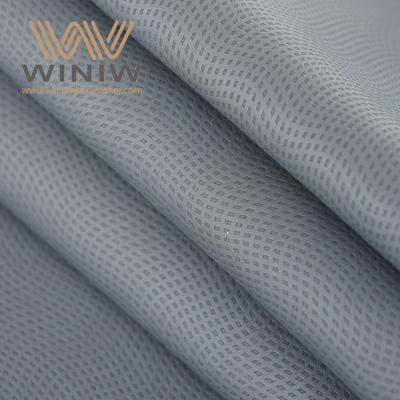

The specialized dust-repellent coating prevents particle adhesion, making it suitable for Class 1000 cleanroom environments. The material is bleach-cleanable, supporting repeated sanitization without losing performance—critical for contamination-controlled electronics manufacturing.

Application Scenarios

For semiconductor manufacturing, 0.8mm thickness and 10⁶–10⁷ ohms anti-static rating meet Class 100 cleanroom standards. The scratch-free suede surface protects microchip wafers from damage, while dexterity supports precise die bonding and wire bonding tasks. Neutral white color enhances contamination detection, and bleach-cleanable properties simplify sanitization between shifts.

For printed circuit board (PCB) assembly lines, 1.0mm thickness and 10⁸–10⁹ ohms rating suit Class 1000 cleanrooms. The material’s static dissipation prevents electrostatic damage to soldered components, while flexibility allows workers to insert tiny connectors and test circuit functionality. Light blue color hides minor dust particles, and abrasion resistance withstands repeated handling of PCB panels.

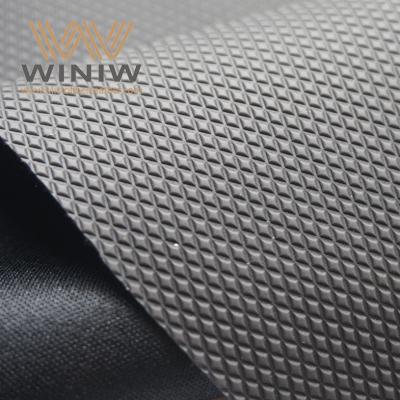

For aerospace and medical electronics component handling, 0.9mm thickness balances protection and sensitivity. The static-dissipative surface safeguards critical components (e.g., pacemaker circuits, aerospace sensors) from static discharge, while the dust-repellent coating prevents particle contamination in high-precision applications. Custom logo embossing adds brand identification for specialized electronics manufacturers.

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

Q: Is WINIW artificial leather eco-friendly?

A: Yes. It uses recycled fibers and water-based PU coatings, free of DMF and heavy metals, with low water consumption in production.

Q: Can it be customized?

A: Yes. Customizable in texture (suede/pebbled), thickness (0.8mm–2.0mm), and Pantone colors, plus logo embossing.

Q: How durable is it compared to natural leather?

A: It has 180,000–250,000 Martindale abrasion cycles, 2–3 times longer service life than natural leather, with good UV/water resistance.

Q: Is it easy to process?

A: Yes. Compatible with CNC cutting, industrial sewing, conductive coating, and reflective printing—no fraying or delamination.

Q: Does it perform well in extreme temperatures?

A: Yes. It stays flexible from -20°C to 60°C, suitable for both winter work gear and outdoor sports products.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com