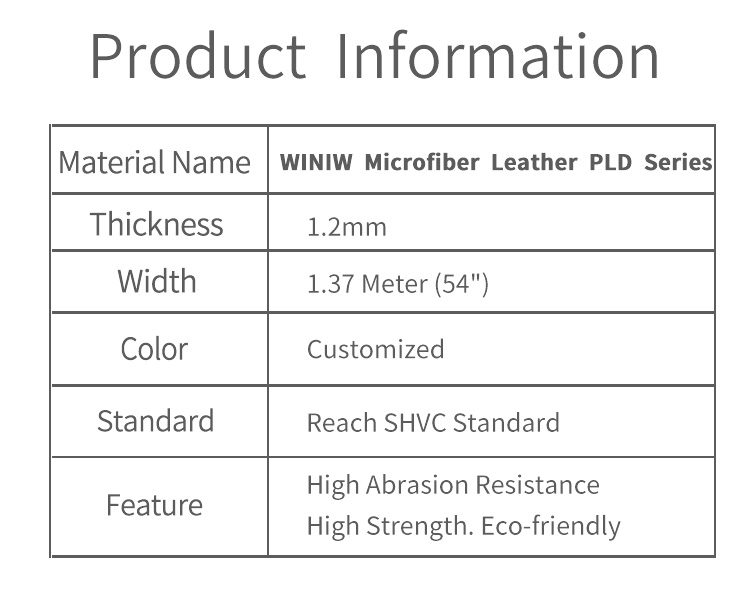

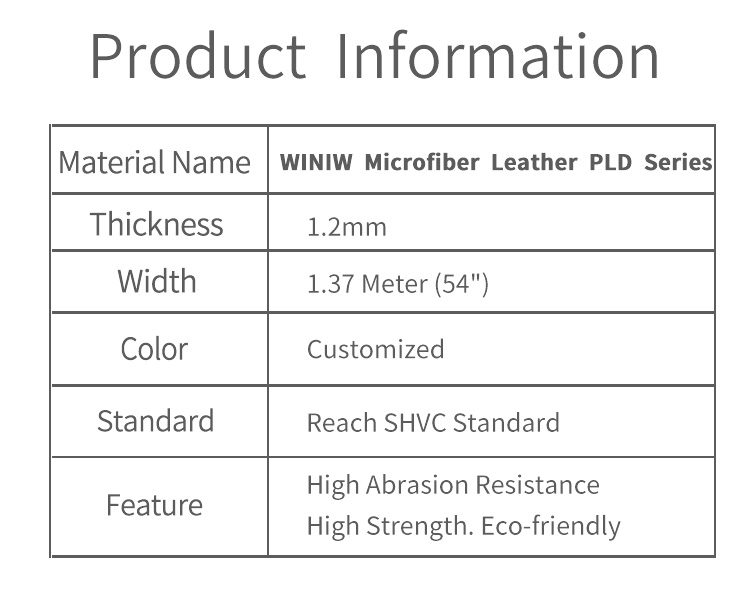

Material Introduction

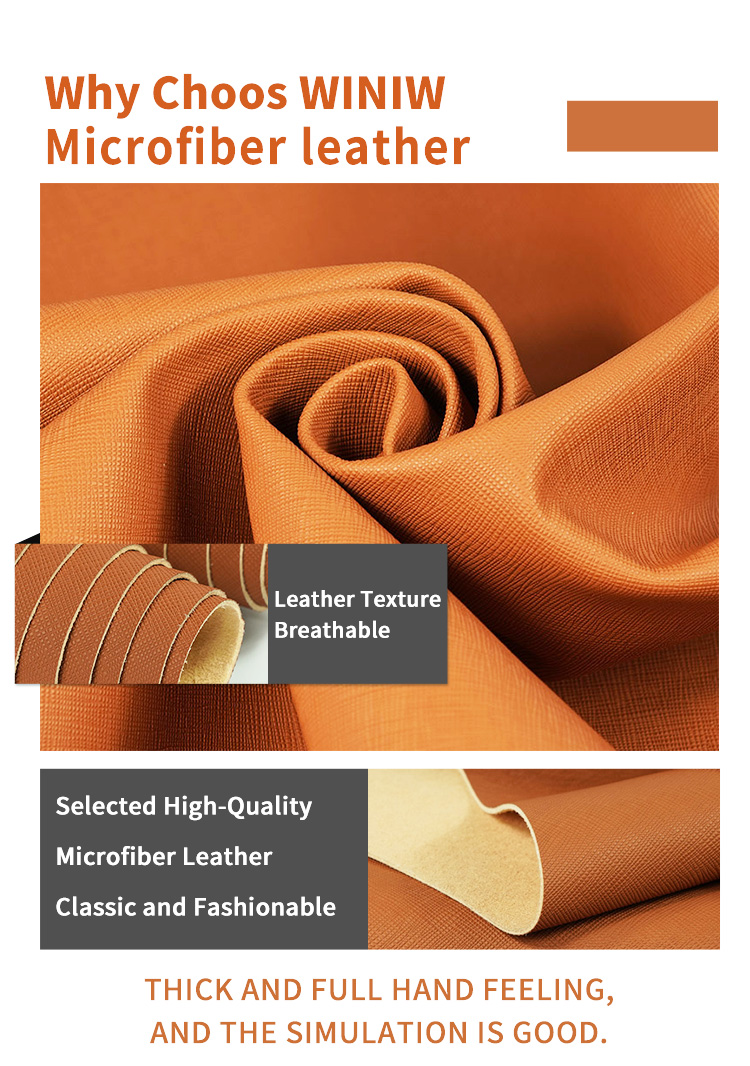

WINIW, a leading provider of process-friendly automotive materials, proudly presents its Suitable For Processing Artificial Leather designed for Vinyl Upholstery. Vinyl upholstery is widely used in automotive applications for its durability, but traditional artificial leathers often pose processing challenges—difficulty in cutting, stitching, or bonding—that slow production and increase waste. This artificial leather addresses these pain points with its optimized formulation, engineered specifically for seamless integration into vinyl upholstery manufacturing processes. Designed for automotive upholstery factories, custom shops, and vinyl product manufacturers, it combines exceptional processability with the strength and aesthetics required for vinyl upholstery. Unlike rigid or inconsistent artificial leathers, it offers consistent thickness, smooth cutting properties, and strong bonding compatibility with vinyl substrates. It also replicates the desired texture and appearance of premium vinyl upholstery, supporting diverse design needs from casual to luxury. The material maintains excellent durability, resisting wear, stains, and UV exposure, ensuring end products meet automotive quality standards. For manufacturers seeking to improve production efficiency, reduce waste, and deliver high-quality vinyl upholstery, WINIW’s Suitable For Processing Artificial Leather is the perfect solution. It streamlines manufacturing processes while enhancing product performance, strengthening competitive advantages in the automotive upholstery market.

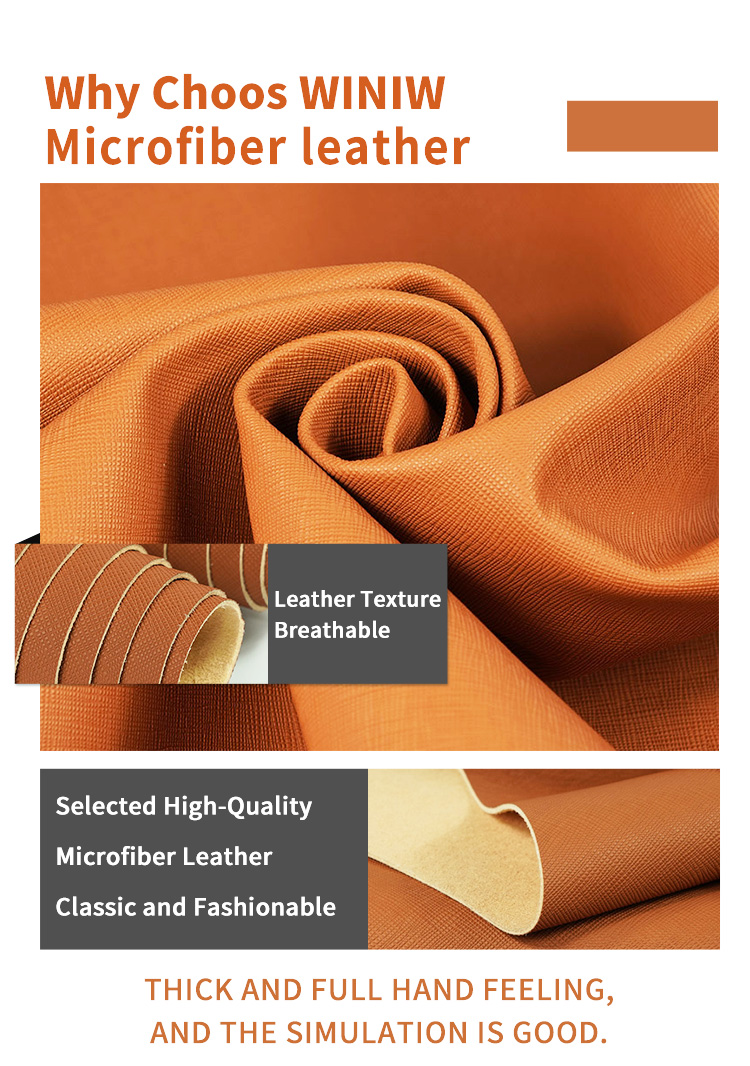

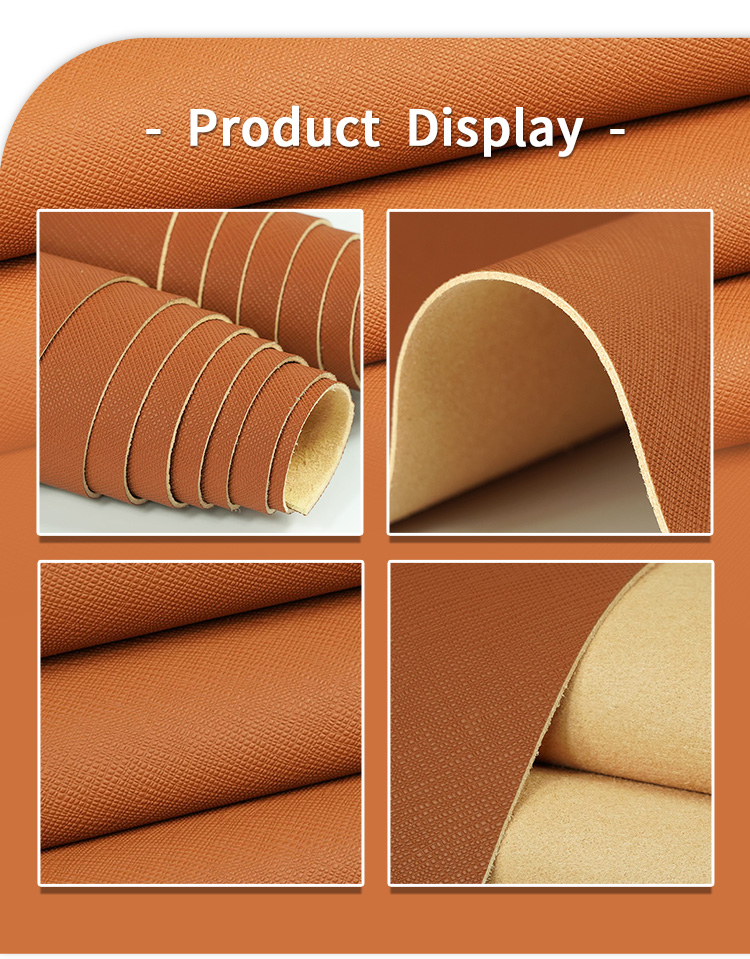

Material Feature

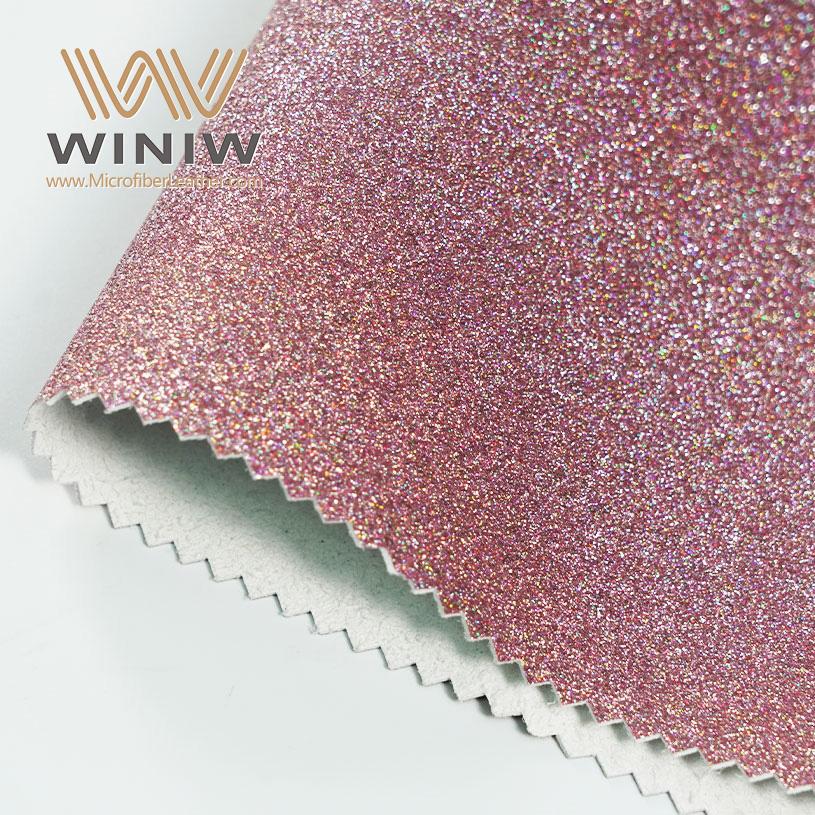

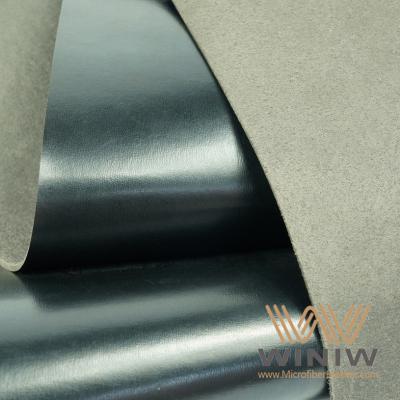

Exceptional Processability

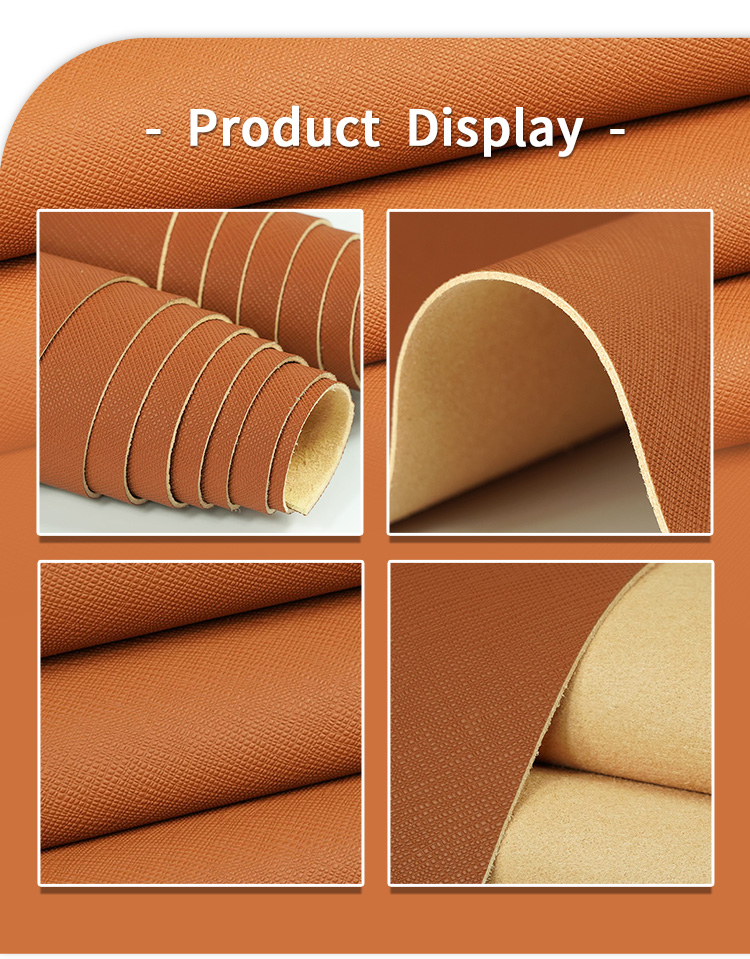

Consistent thickness and stable structure enable clean, precise cutting without fraying. Feeds smoothly into stitching machines and bonds seamlessly with vinyl substrates via standard methods, reducing production time and material waste.

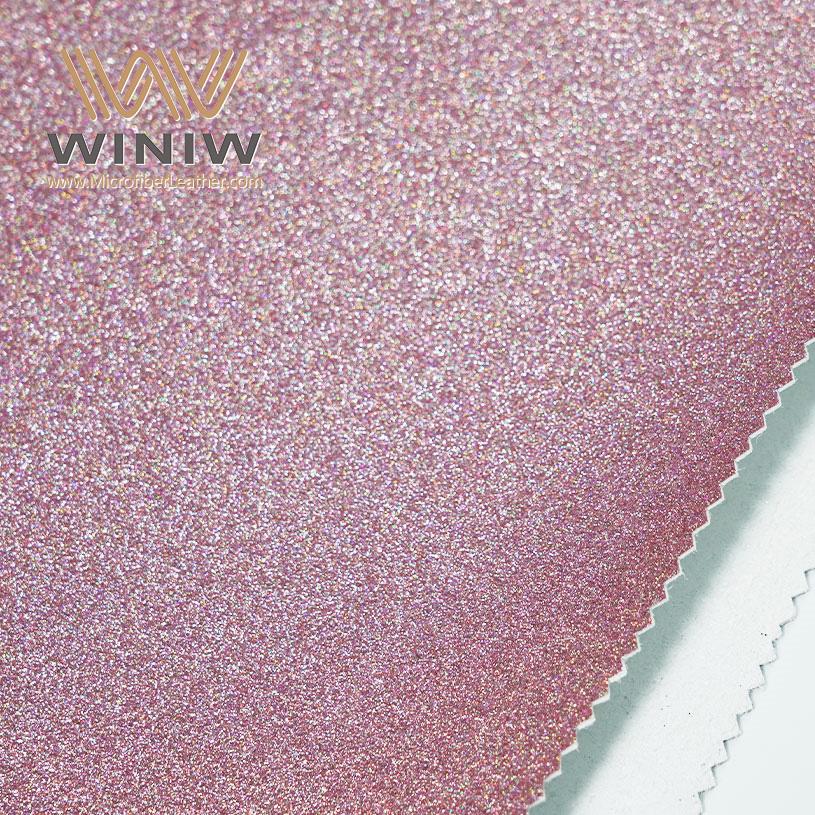

Vinyl Upholstery Compatibility

Replicates the texture and appearance of premium vinyl, matching diverse design requirements. Strong adhesion with vinyl substrates ensures long-term bonding without delamination, maintaining structural integrity of upholstery components.

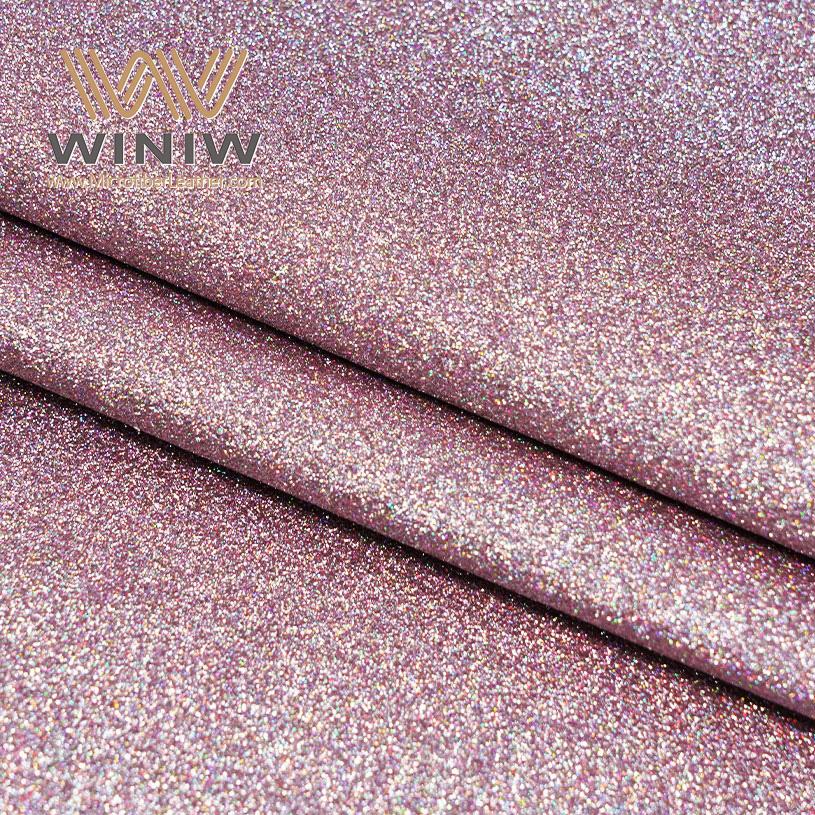

Durable Performance

Exhibits strong wear resistance against seating pressure and friction. UV-resistant and temperature-stable, preventing fading, cracking, or brittleness. Stain-resistant surface allows easy cleaning, ensuring long-term appearance and functionality.

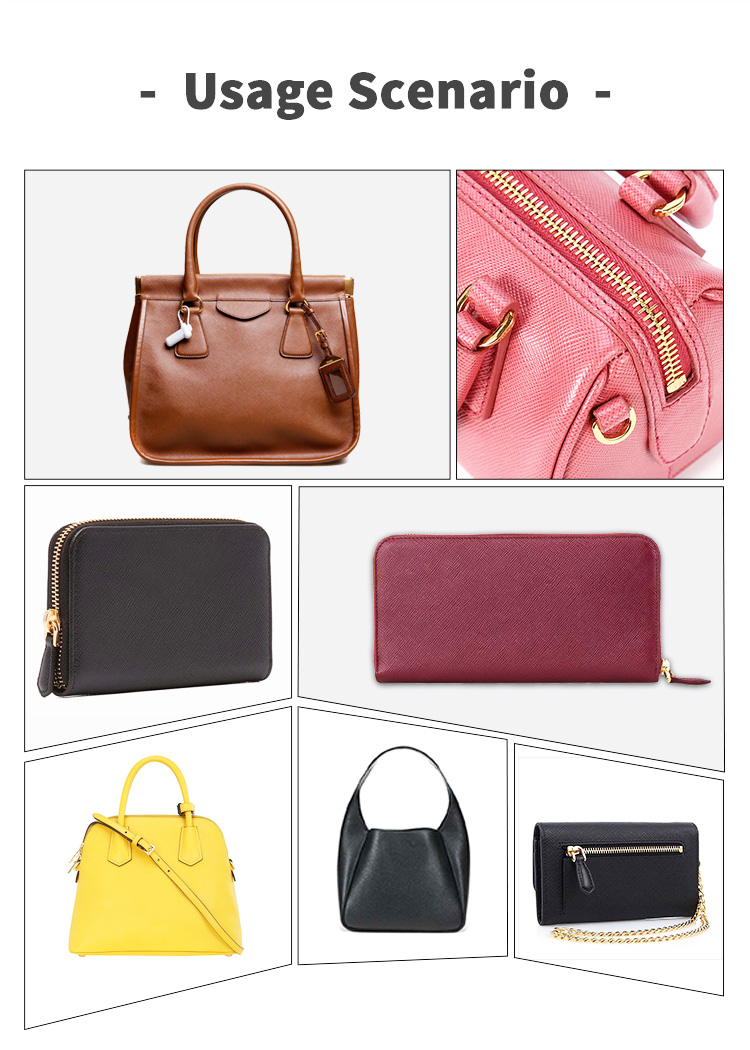

Application Scenarios

Automotive Seat Upholstery

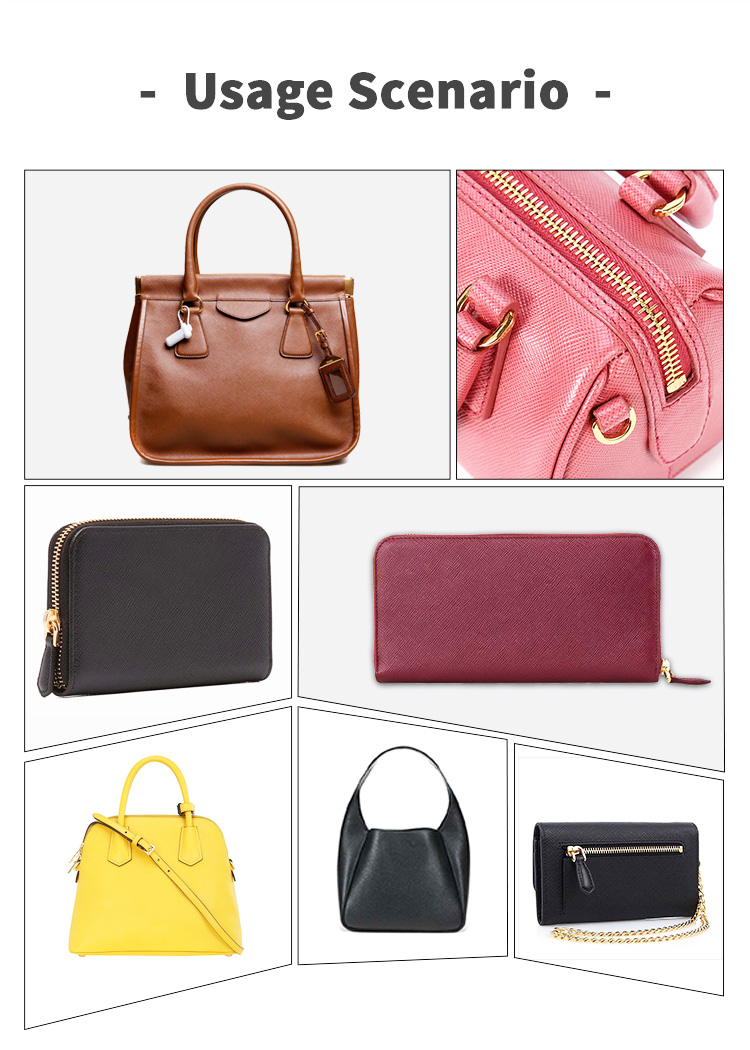

Ideal for manufacturing vinyl seat covers and cushions. Easy cutting and stitching enable precise fitting to seat frames, while strong bonding with vinyl ensures durability. Its wear resistance and comfort stand up to daily seating use, maintaining appearance over time.

Door Panels & Interior Trim

Suitable for door panels, armrests, and interior trim components. It bonds seamlessly with vinyl substrates, forming smooth, attractive surfaces. Its processability allows for integration with cutouts for handles or controls, supporting complex interior designs.

Convertible & Exterior Upholstery

Great for convertible tops, exterior door trim, and truck bed covers. UV resistance and weather durability withstand outdoor exposure, while easy processing enables the formation of large, curved components. Its stain resistance ensures easy maintenance of exterior upholstery.

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

1. Is this material compatible with automated cutting and stitching equipment used in large-scale upholstery production?

Yes, it is optimized for automated manufacturing. Its consistent thickness and stable structure feed smoothly into automated cutters and stitchers, producing precise, uniform results that reduce production errors and increase efficiency.

2. Can it be bonded with different types of vinyl substrates, such as rigid or flexible vinyl?

Absolutely. It features versatile adhesion properties that bond securely with both rigid and flexible vinyl substrates. Standard bonding methods like heat pressing or industrial adhesives yield strong, long-lasting bonds regardless of vinyl type.

3. Will it maintain its texture and appearance after being formed into curved upholstery components like seat cushions?

Yes, it has excellent formability. It can be shaped into curved or contoured components without losing texture or structural integrity. It retains its shape and appearance after forming, ensuring consistent quality across all upholstery parts.

4. Is it suitable for producing both interior and exterior vinyl upholstery components?

Yes, it is suitable for both interior and exterior use. Its UV resistance and weather durability make it ideal for exterior components like convertible tops or door trim, while its aesthetic quality and comfort suit interior upholstery needs.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com