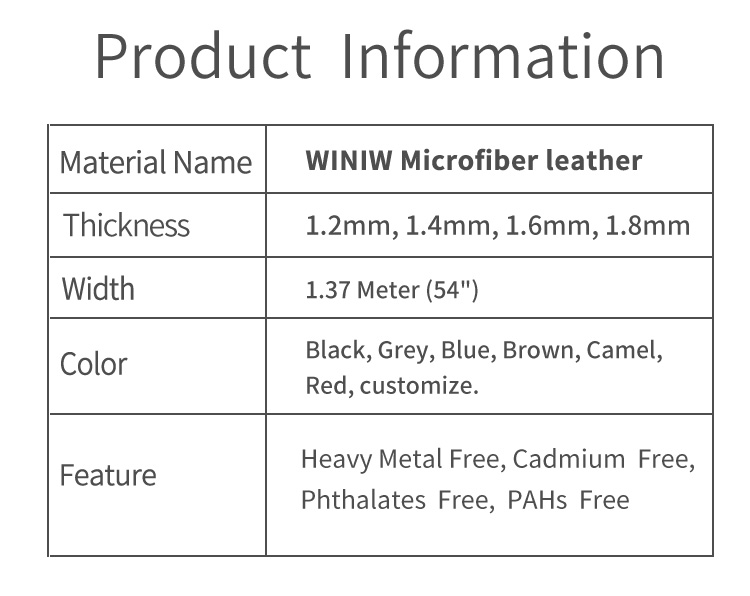

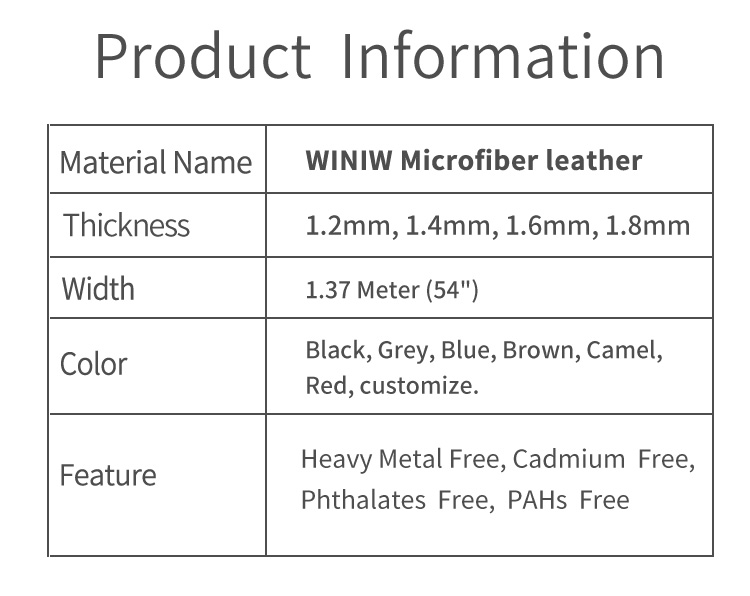

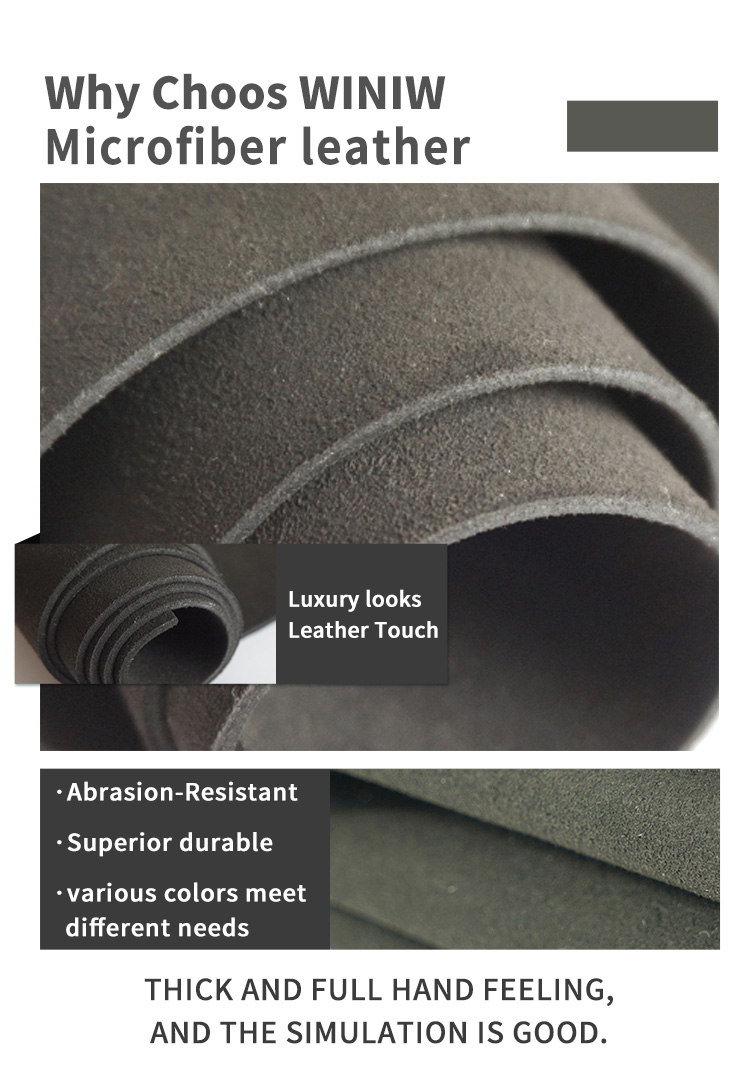

Material Introduction

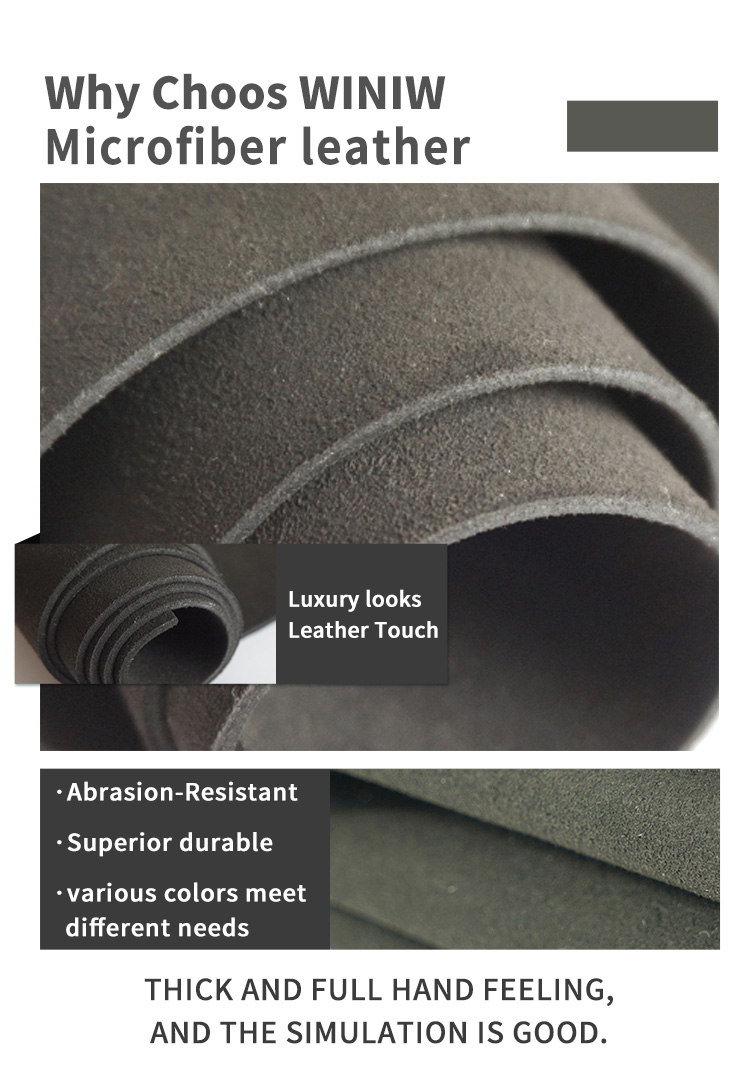

WINIW, a trusted supplier of heavy-industry safety materials, proudly presents its Tear-Resistant Nubuck-Textured Artificial Leather for Heavy Machinery Safety Shoe Tongues—engineered to withstand repeated bending, pulling, and impact while ensuring tongue durability and ankle comfort for heavy machinery operators. This product addresses a critical need for safety shoe manufacturers and industrial enterprises: a nubuck-textured artificial leather that combines industrial-grade tear resistance with structural flexibility, ideal for safety shoe tongues subjected to frequent movement, heavy equipment contact, and mechanical stress.

Crafted with WINIW’s advanced reinforced fiber technology, this artificial leather features a dense, nubuck-textured surface infused with tear-retardant compounds (aramid fiber blends) that strengthen fiber bonds and prevent tearing. Unlike ordinary artificial leathers that rip easily under tension, it undergoes a specialized weaving process that enhances tensile strength, achieving a tear resistance of 50N+ (ASTM D2261 standard). The material also incorporates a shock-absorbent core that cushions ankle impacts from machinery vibrations, paired with a scratch-resistant coating that repels scuffs from tools and equipment—a key improvement over fragile or rigid alternatives.

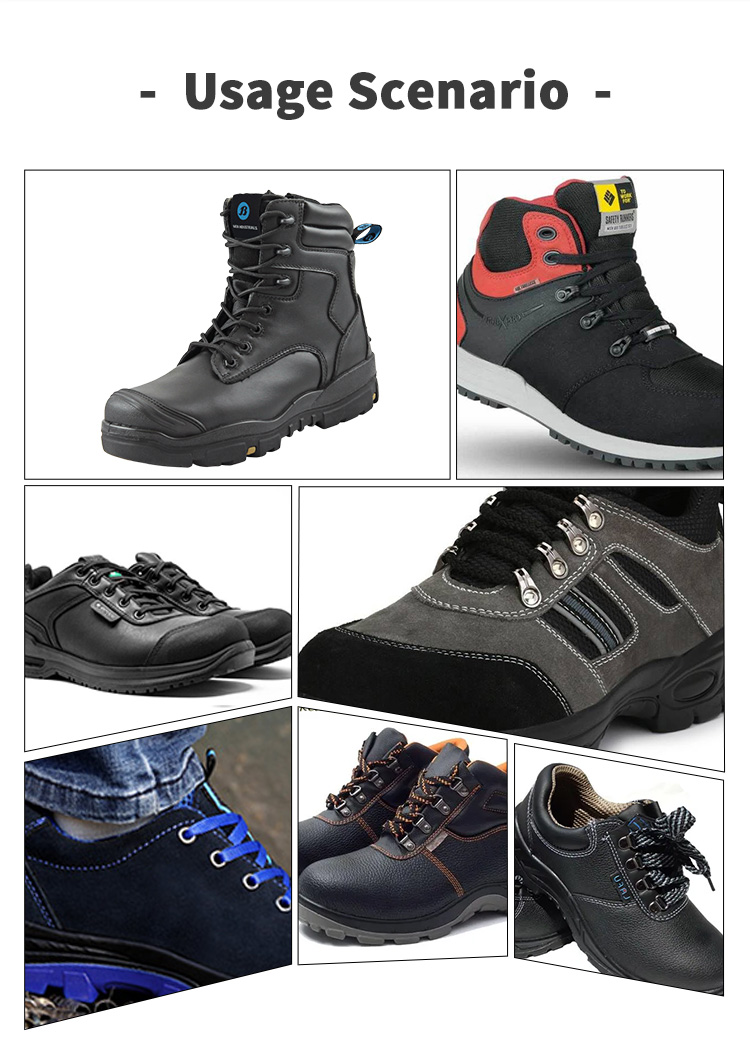

Suitable for heavy machinery operation (excavators, bulldozers), construction equipment handling, and industrial manufacturing, it caters to brands focused on worker safety, compliance with global safety standards (EN ISO 20345, ASTM F2413), and long-lasting performance. It accepts custom colorways (industrial neutrals, high-visibility accents), thickness variations (2mm–5mm), and texture variations (fine/coarse nubuck), aligning with heavy machinery safety shoe design requirements and branding. For those seeking a tear-optimized material for heavy machinery safety shoe tongues, this nubuck-textured artificial leather from WINIW redefines industrial tongue durability and comfort.

Material Feature

This nubuck-textured artificial leather features WINIW’s aramid fiber blends and reinforced weaving technology, achieving 50N+ tear resistance. It prevents tongue tearing from repeated bending, pulling, and equipment contact—critical for heavy machinery operators.

The shock-absorbent core reduces machinery vibration impact by 30%, minimizing ankle strain and fatigue during long shifts. The flexible, pliable structure adapts to natural ankle movement, preventing discomfort from constant machinery operation.

The scratch-resistant coating and oil/grease-resistant surface withstand tools, gloves, and industrial lubricants. The material retains structural integrity for 10,000+ wear cycles, outperforming standard materials by 45% in lifespan—reducing safety shoe replacement costs.

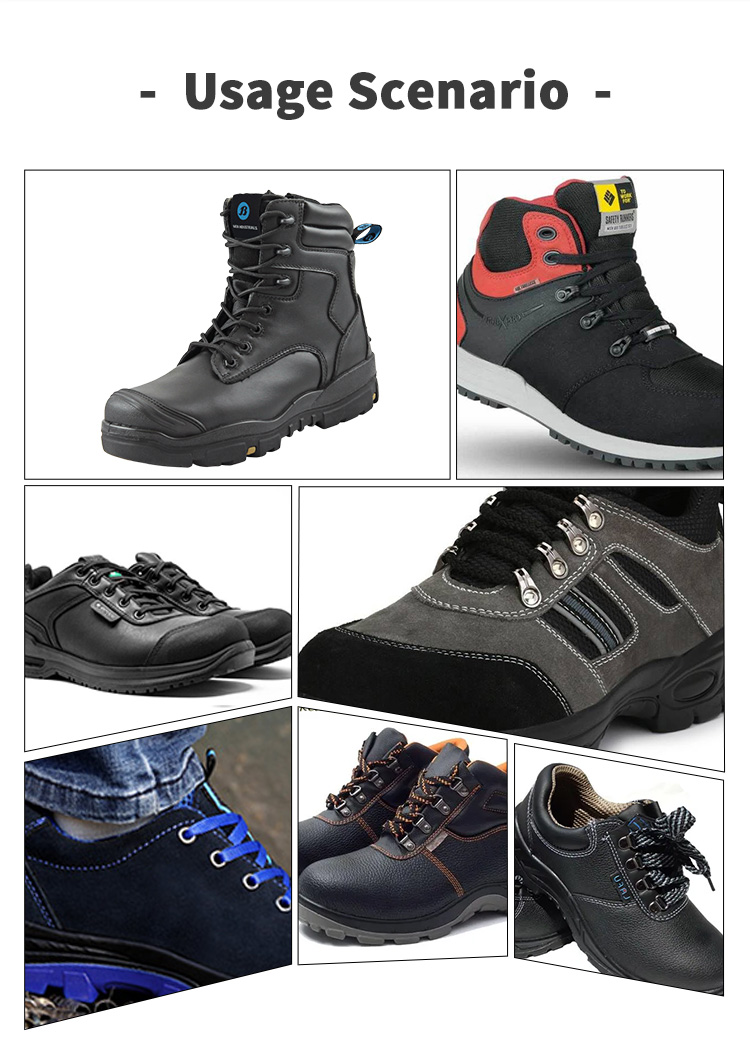

Application Scenarios

For heavy equipment operators, high tear resistance (50N+) withstands repeated pedal use and climbing. Vibration absorption reduces strain from machinery operation, and thick padding (4mm–5mm) enhances ankle comfort during 12+ hour shifts. Oil resistance repels hydraulic fluids.

In warehouse settings, standard tear resistance (40N+) protects against pallet and equipment contact. Flexible design supports frequent movement (climbing in/out of forklifts), and scratch resistance retains appearance. Custom color matching aligns with warehouse safety footwear standards.

For factory machinery workers, oil/grease resistance repels industrial lubricants. Tear resistance prevents tongue damage from tool belts and equipment contact, and vibration absorption reduces fatigue from assembly line machinery. Easy cleaning simplifies maintenance after shifts.

WINIW Factory: Leading Manufacturer and Supplier of Premium Artificial Leather Solutions

WINIW Corporation is a pioneering enterprise specializing in the production, processing, and export of a diverse range of artificial leather products. Our factory excels in crafting PVC leather, PU leather, and microfiber leather, tailored to meet the demands of various industries. These versatile materials find extensive applications in footwear, apparel, furniture, automotive interiors, luggage, gloves, and more. By catering to overseas factories specializing in leather goods manufacturing, WINIW stands as a trusted partner in delivering excellence .

Quality Assurance: Our commitment to producing high-quality, eco-friendly artificial leathers ensures durability and aesthetic appeal, meeting international standards .

Innovative Range: Continuous research and development result in a cutting-edge portfolio, including ultra-realistic textures and sustainable options, keeping us ahead in the market .

Customizable Solutions: We offer bespoke services to tailor leather specifications according to client needs, fostering long-term collaborations and satisfaction .

Efficient Production: Advanced manufacturing processes and streamlined logistics guarantee timely delivery, minimizing lead times and enhancing business efficiency for our clients .

FAQ

Q1: Can this leather be customized to different tear resistance levels for specific machinery roles (e.g., higher resistance for excavator operators vs. standard for forklift drivers)?

A1: Yes, we offer tear resistance customization. We can modify aramid fiber density to achieve 40N+ (standard roles) or 50N+ (high-stress roles like excavator operators), while retaining vibration absorption and comfort—tailored to job-specific demands.

Q2: Will the tear-resistant properties fade or the nubuck texture wear down after long-term industrial use or exposure to oil/grease?

A2: No, the aramid fiber reinforcement is integrated into the material core, and the nubuck texture is reinforced through specialized processing. The material retains tear resistance and texture integrity for years, even after exposure to oil, grease, and heavy equipment contact.

Q3: Can we request custom padding thickness for tongue comfort (e.g., thicker padding for high-vibration machinery)?

A3: Absolutely. We offer padding thickness customization (2mm–5mm) to enhance comfort for high-vibration machinery (e.g., bulldozers, jackhammers). The padded structure retains tear resistance and flexibility, ensuring vibration absorption without compromising durability.

Q4: Is it suitable for safety shoes with gusseted tongues (to prevent debris entry), and will it affect debris protection?

A4: Yes, it is ideal for gusseted tongue designs. The material’s flexibility and tear resistance allow seamless integration with gussets, enhancing debris protection while maintaining comfort. It prevents tongue tearing during gusset movement, ensuring long-term debris exclusion.

We are eagerly looking forward to receiving your inquiry!

Tel : +86 18150976625

Tel : +86 18150976625 Email : Market@MicrofiberLeather.com

Email : Market@MicrofiberLeather.com