Synthetic leather, often called faux leather, refers to a material designed to replicate genuine leather’s appearance and texture. Manufacturers produce it by coating a fabric base, such as cotton or polyester, with plastics like polyurethane (PU) or polyvinyl chloride (PVC). The following table highlights the most common combinations:

|

Base Material |

Type of Plastic Used |

|---|---|

|

Cotton |

PVC |

|

Polyester |

PU |

This approach provides a cost-effective, low-maintenance alternative to real leather.

Faux leather, also known as synthetic leather, mimics the look and feel of genuine leather without using animal products.

Manufacturers create faux leather by coating fabric bases like cotton or polyester with plastics such as polyurethane (PU) or polyvinyl chloride (PVC).

Faux leather is more affordable than real leather, making it a popular choice for budget-conscious consumers seeking stylish options.

This material is easy to maintain; regular cleaning requires only a damp cloth and mild soap, saving time and effort.

Faux leather is animal-friendly, appealing to consumers who prioritize ethical choices in fashion and home decor.

While faux leather offers durability, it may not last as long as genuine leather and can show signs of wear over time.

Environmental concerns exist due to the petroleum-based materials used in faux leather production, highlighting the need for sustainable alternatives.

Different types of faux leather, such as PU, PVC, and bio-based options, offer varying benefits and drawbacks, allowing consumers to choose based on their needs.

Faux leather, also known as synthetic leather or vegan leather, is a material designed to imitate the look and feel of genuine leather. Manufacturers create it using synthetic substances such as polyurethane (PU) or polyvinyl chloride (PVC). This process does not involve animal products, making faux leather a cruelty-free and cost-effective alternative to traditional leather. The textile and fashion industries often refer to artificial leather as pleather, highlighting its plastic origins and versatility. Faux leather vs other fabrics shows that this material stands out for its ability to mimic leather’s texture and appearance while offering easier maintenance.

Faux leather possesses several physical and chemical characteristics that distinguish it from other synthetic materials. The following table summarizes these features:

|

Feature |

Faux Leather Type |

Distinction from Other Synthetic Materials |

|---|---|---|

|

Base Fabric Structure |

Varies (e.g., non-woven, knitted) |

Different base fabrics affect texture and durability. |

|

Resin Type |

PU, PVC |

PU has better abrasion resistance and mechanical properties than PVC. |

|

Surface Structure |

Microporous for microfiber |

Imitates leather grain structure, enhancing realism. |

|

Durability |

High (especially PU) |

More durable than many other synthetic options. |

Manufacturers select the base fabric and resin type to achieve a realistic leather grain and improve durability. Faux leather vs other fabrics demonstrates superior abrasion resistance and mechanical strength, especially when using PU coatings. The microporous surface structure allows for a more realistic texture, making artificial leather a preferred choice in applications where appearance matters.

The comparison between faux leather and real leather reveals important differences in appearance, texture, and cost. Laboratory testing highlights several distinctions:

Feel: Real leather feels warm and soft, with a slight give. Faux leather feels colder and more plastic-like.

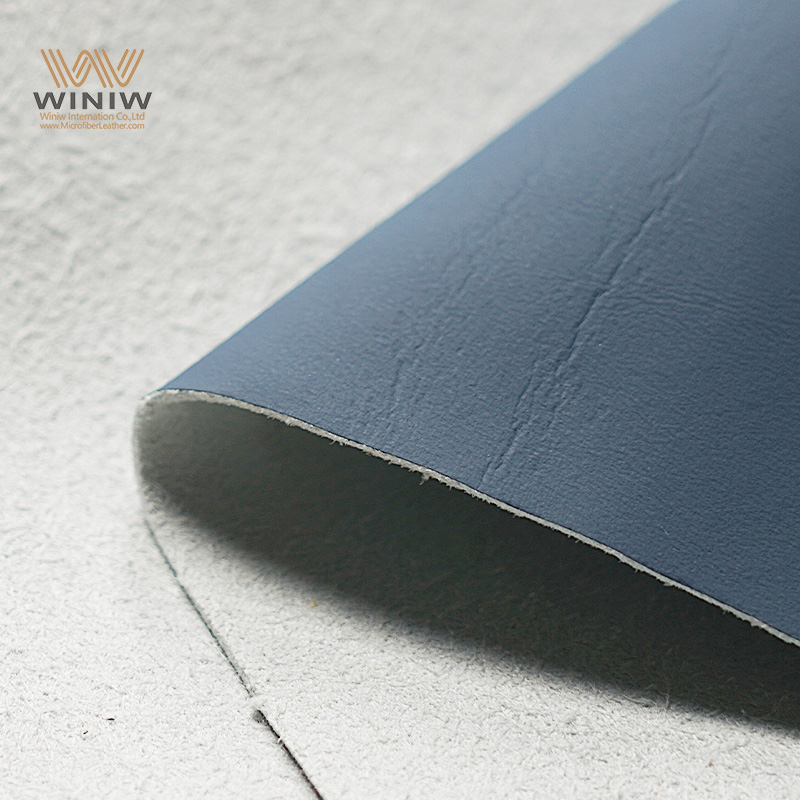

Grain Structure: Genuine leather displays an irregular grain pattern. Faux leather shows a repetitive, embossed pattern.

Uniformity: Faux leather often appears flawless. Real leather features natural imperfections.

Plastic Sheen: Faux leather has a shiny, plastic-like gloss. Real leather offers a subtle finish.

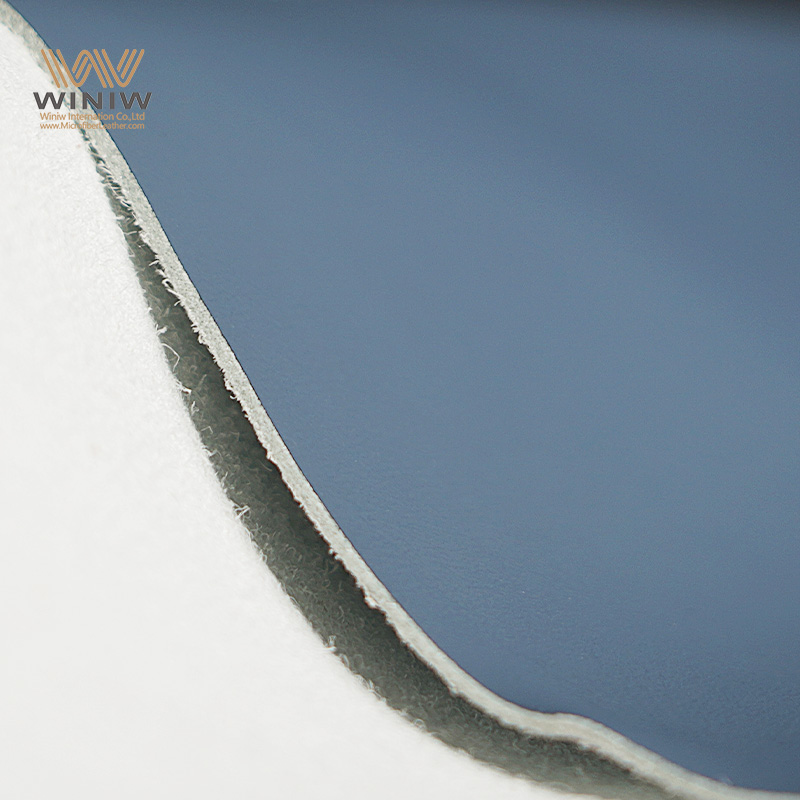

Edges: Real leather has rough, fibrous edges. Faux leather presents smooth, clean-cut edges.

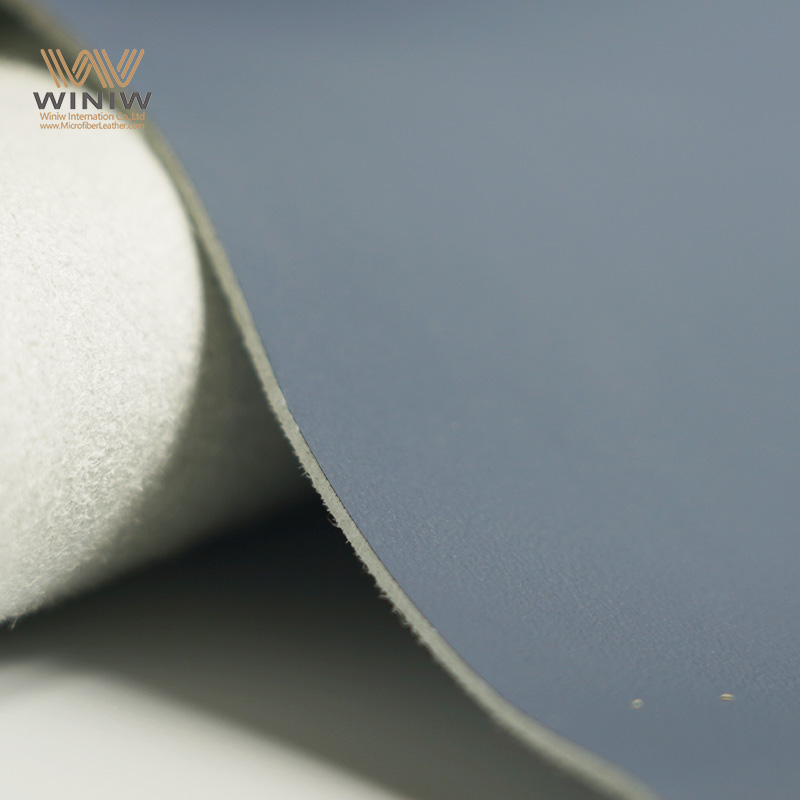

Backside: Real leather has a suede-like underside. Faux leather reveals a synthetic backing.

Breathability: Real leather is porous, allowing air and moisture to pass. Faux leather traps heat and moisture, which can cause discomfort.

The cost difference between faux leather vs real leather is significant. The following table illustrates average market prices:

|

Leather Type |

Cost Comparison |

|---|---|

|

Real Leather |

Most Expensive |

|

Faux Leather |

Less Expensive than Real Leather, More than Bonded Leather |

|

Bonded Leather |

Least Expensive |

Faux leather vs bonded leather shows that faux leather offers better durability and a more realistic appearance than bonded leather, which consists of leather scraps bonded together. Pleather remains a popular choice for consumers seeking style and affordability. Faux leather vs other fabrics also demonstrates that faux leather provides a unique combination of aesthetics and performance not found in standard textiles.

Tip: When choosing between faux leather and real leather, consider the intended use, budget, and desired appearance. Faux leather offers a practical solution for those seeking style and easy care at a lower price point.

The production process for faux leather involves several precise steps, each contributing to the final quality and performance of synthetic leather. Manufacturers select specific fabric base materials and coating substances to achieve the desired texture, durability, and appearance.

The foundation of faux leather fabric relies on strong and flexible textiles. Polyester stands out as the most common choice in faux leather production due to its durability and resistance to stretching and shrinking. Other materials such as cotton, nylon, and rayon also play roles in the industry.

|

Base Material |

Properties |

|---|---|

|

Polyester |

Durable, resistant to stretching and shrinking |

|

Cotton |

Soft, breathable, and comfortable |

|

Nylon |

Strong, elastic, and resistant to mildew |

|

Rayon |

Soft, smooth, and absorbent |

Polyester provides a stable and resilient base for faux leather fabric. Its synthetic fibers withstand repeated stress and maintain shape over time. Manufacturers favor polyester for its ability to bond effectively with coatings, ensuring a consistent surface and reliable performance in faux leather production.

The coating process transforms the fabric base into a material that closely resembles genuine leather. Manufacturers use petroleum-based polymers to create the synthetic layer that defines faux leather.

Polyurethane serves as a popular coating in faux leather production. This polymer offers flexibility, abrasion resistance, and a soft touch. PU coatings create a realistic leather-like texture and enhance water and scratch resistance. However, PU’s low biodegradability and high energy consumption during production raise sustainability concerns.

Polyvinyl chloride provides another common option for faux leather coatings. PVC delivers a glossy finish and robust durability. The production process for PVC-based synthetic leather involves mixing PVC with pigments and applying it to the fabric base. PVC’s economic advantages make it attractive, but its environmental impact includes microplastic release and poor biodegradability.

Manufacturers apply wax and dye during the finishing stages to achieve specific colors and surface effects. These substances enhance the visual appeal and tactile qualities of faux leather fabric, allowing for a wide range of styles in faux leather production.

The production process for faux leather fabric consists of several key stages. Each step influences the final product’s quality, durability, and appearance.

|

Type of Faux Leather |

Manufacturing Steps |

|---|---|

|

1. Mix PVC and pigments, coat on fabric to create base material. 2. Foaming process to thicken PVC layer. 3. Embossing for texture. 4. Surface treatment for color and designs. |

|

|

1. Wet backing fabric, coat with polyurethane. 2. Solidify using DMF, wash, and dry. 3. Coat with half-dry PU layer, bake, and separate from release paper. |

|

|

Similar to PU leather, using microfiber base. |

|

|

Coated silicone on fabric, similar to dry PU method. |

Manufacturers begin faux leather production by applying the chosen polymer—PU or PVC—to the fabric base. This synthetic layer determines the material’s appearance and texture. The coating process directly affects durability, water resistance, and scratch resistance. The backing fabric supports the coating, providing structure and flexibility.

Embossing and foaming techniques create the distinctive grain pattern found in faux leather fabric. These methods replicate the irregular texture of genuine leather. Texturizing enhances the realism and tactile appeal of synthetic leather, making it suitable for various applications.

The final stage in faux leather production involves surface treatments such as waxing, dyeing, and baking. These finishing processes set the color, add gloss or matte effects, and improve resistance to wear. Manufacturers may separate the finished faux leather from release paper to reveal a smooth, consistent surface.

Note: The choice of base material and coating in faux leather production determines the product’s strength, flexibility, and environmental footprint. Manufacturers must balance performance with sustainability concerns, especially when using petroleum-based polymers.

The production process for faux leather fabric continues to evolve as manufacturers seek improved durability, realistic appearance, and reduced environmental impact. Understanding how faux leather is manufactured helps consumers make informed choices about synthetic leather products.

PU faux leather stands out as one of the most popular types of faux leather fabric in the market. Manufacturers create PU leather by coating a layer of polyurethane on a fabric base, often polyester. This process results in a material with a sleek and glossy finish, which appeals to consumers seeking a realistic alternative to genuine leather. PU faux leather fabric finds frequent use in fashion items such as jackets, handbags, and shoes. Many designers prefer PU leather because it does not use animal hide, making it an animal-friendly option. The versatility of PU faux leather allows for a wide range of colors and textures, giving manufacturers the ability to produce artificial leather that closely mimics the look and feel of traditional leather.

Tip: PU faux leather offers a balance between style and affordability, making it a top choice for those who want the appearance of leather without the ethical concerns.

Key Features of PU Faux Leather:

Polyurethane coating on fabric base

Sleek, glossy, and realistic finish

Widely used in fashion and accessories

Animal-friendly and versatile

PVC faux leather fabric represents another major category among types of faux leather. Manufacturers produce PVC leather by applying polyvinyl chloride to a textile base, often using cotton or polyester. PVC faux leather stands out for its shiny appearance and robust structure, which makes it suitable for furniture, automotive interiors, and pleather goods. However, PVC leather tends to be more susceptible to cracking and peeling compared to other types of faux leather fabric. This reduced durability leads to a shorter lifespan and increased waste. The environmental impact of PVC production raises concerns, as it releases toxic dioxins and contributes to plastic pollution. PVC is not biodegradable and can persist in landfills for hundreds of years.

Distinguishing Features of PVC Faux Leather:

Polyvinyl chloride coating on textile base

Shiny, sturdy, and easy to clean

Prone to cracking and peeling over time

Significant environmental concerns due to non-biodegradability

Note: Consumers should weigh the durability and environmental impact of PVC faux leather before choosing it for long-term applications.

Silicone-based synthetic leather has emerged as a modern alternative within the types of faux leather fabric. Manufacturers use silicone coatings on fabric bases to create a material free from animal products and certain harmful chemicals. Silicone-based artificial leather offers unique properties, including high resistance to environmental factors such as UV rays, moisture, and temperature changes. This type of faux leather fabric demonstrates high durability and requires minimal maintenance, making it suitable for commercial and outdoor applications. Silicone-based synthetic leather also boasts eco-friendliness, as it has a lower environmental impact compared to PU and PVC leathers. Its water resistance and stain resistance add to its practicality for daily use.

Advantages of Silicone-Based Synthetic Leather:

Free from animal products and toxic chemicals

High resistance to wear, tear, and environmental stress

Eco-friendly and sustainable

Minimal care required to maintain appearance

Excellent water and stain resistance

Block Quote: Silicone-based synthetic leather provides a sustainable solution for manufacturers seeking durability and environmental responsibility in faux leather fabric.

Bio-based faux leather represents a significant advancement in sustainable materials. Manufacturers produce this type of faux leather fabric using renewable resources, including plant proteins, mycelium, and natural fibers. These ingredients contribute to an eco-friendly profile and reduce reliance on petroleum-based polymers.

The production process for bio-based faux leather follows several distinct steps:

Bio-cultivation: Plant fibers and mycelium undergo fermentation under controlled conditions.

Material formation: The mixture develops leather-like strength and texture.

Eco-finishing: Chrome-free tanning and plant-based dyes enhance the final product.

Performance testing: Rigorous quality checks ensure physical and mechanical properties meet industry standards.

This method allows manufacturers to create faux leather fabric that closely mimics the appearance and feel of traditional leather. Bio-based options often feature improved breathability and flexibility compared to conventional synthetic alternatives. The use of plant-based dyes and chrome-free tanning reduces the environmental impact of the finishing process.

Note: Bio-based faux leather offers a solution for brands seeking to lower their carbon footprint and appeal to environmentally conscious consumers.

A comparison of bio-based faux leather with other types of faux leather highlights its unique benefits:

|

Feature |

Bio-Based Faux Leather |

PU/PVC Faux Leather |

|---|---|---|

|

Raw Materials |

Plant fibers, mycelium |

Petroleum-based |

|

Eco-Friendliness |

High |

Low |

|

Breathability |

Improved |

Limited |

|

Biodegradability |

Yes |

No |

|

Color Options |

Plant-based dyes |

Synthetic dyes |

Bio-based faux leather fabric continues to gain popularity in fashion, accessories, and automotive interiors. Brands value its sustainable origins and innovative production methods.

Recycled faux leather fabric addresses the growing demand for circular materials in the textile industry. Manufacturers create this type of faux leather by repurposing post-consumer plastics, discarded textiles, and industrial waste. The recycling process transforms these materials into new synthetic fibers, which then serve as the base for faux leather coatings.

The main steps in recycled faux leather production include:

Collection and sorting of waste materials.

Mechanical or chemical recycling to produce usable fibers.

Application of PU or PVC coatings to create a finished faux leather fabric.

Recycled faux leather offers several advantages. It diverts waste from landfills, reduces resource consumption, and supports a circular economy. Many brands use recycled faux leather fabric in footwear, bags, and upholstery to promote sustainability.

Tip: Recycled faux leather provides a practical option for companies aiming to reduce environmental impact without sacrificing style or durability.

A summary of recycled faux leather compared to other types of faux leather:

|

Feature |

Recycled Faux Leather |

PU/PVC Faux Leather |

|---|---|---|

|

Source Material |

Post-consumer waste |

Virgin polymers |

|

Environmental Impact |

Reduced |

Higher |

|

Durability |

Comparable |

High |

|

Cost |

Moderate |

Varies |

|

Applications |

Fashion, furniture |

Wide-ranging |

Recycled faux leather fabric demonstrates how innovation in material sourcing can drive sustainability in the industry. As technology advances, recycled options will likely become more prevalent among the types of faux leather available to consumers.

Many consumers consider cost as a primary factor when selecting materials for clothing, furniture, or accessories. Faux leather offers a significant price advantage over genuine leather. Manufacturers produce vegan leather using synthetic processes that require less labor and fewer resources than traditional leather tanning. This efficiency leads to lower retail prices.

Retailers often highlight the benefits of choosing faux leather for budget-conscious shoppers. The material provides a stylish appearance without the premium cost associated with animal hides. Designers can create realistic finishes that mimic the look of luxury goods, making vegan leather accessible to a wider audience.

The following table compares average price ranges for common products:

|

Product Type |

Genuine Leather |

Faux Leather |

|---|---|---|

|

Handbags |

$150 - $500 |

$30 - $120 |

|

Jackets |

$200 - $800 |

$40 - $180 |

|

Sofas |

$1,000 - $3,000 |

$350 - $900 |

Tip: Shoppers who prioritize affordability and style often find the benefits of choosing faux leather align with their needs.

Faux leather stands out for its easy maintenance. Owners do not need specialized cleaning products or time-consuming care routines. Most vegan leather items require only a damp cloth for regular cleaning. Stains and spills rarely penetrate the surface, which helps preserve the material’s appearance.

Manufacturers design faux leather to resist fading and discoloration. Unlike genuine leather, which may require conditioning and protection from moisture, vegan leather maintains its look with minimal effort. This feature appeals to busy individuals and families who want durable products without extensive upkeep.

A simple cleaning routine for faux leather includes:

Wipe the surface with a soft, damp cloth.

Use mild soap for stubborn stains.

Dry with a clean towel to prevent water spots.

Block Quote: The benefits of choosing faux leather extend to hassle-free maintenance, making it ideal for everyday use.

Water and scratch resistance represent key advantages of faux leather. Manufacturers engineer the surface to repel liquids, preventing damage from spills or humidity. This property makes vegan leather suitable for environments where moisture exposure is common, such as kitchens, cars, or outdoor furniture.

The synthetic coating also provides a protective barrier against scratches and abrasions. Children, pets, and frequent use do not easily mar the surface. The realistic texture remains intact even after repeated contact.

A summary of water and scratch resistance features:

Repels water and prevents staining

Resists scratches from daily wear

Maintains a realistic appearance over time

Suitable for high-traffic areas

Note: Water and scratch resistance contribute to the long-term benefits of choosing faux leather for both residential and commercial applications.

Faux leather appeals to consumers who prioritize animal welfare. Manufacturers produce this material without using animal hides or byproducts. The process relies on synthetic polymers such as polyurethane and polyvinyl chloride, which replicate the look and feel of genuine leather. This approach eliminates the need for animal slaughter, making faux leather a preferred choice for individuals who follow vegan or cruelty-free lifestyles.

Many brands market faux leather as "vegan leather" to highlight its animal-friendly nature. Designers use this term to attract customers who seek ethical alternatives in fashion, furniture, and automotive interiors. The absence of animal-derived ingredients sets faux leather apart from traditional leather goods. Retailers often display vegan certification labels to assure buyers of the product's origins.

Consumers increasingly demand transparency regarding the materials used in their purchases. Several organizations offer certifications and standards that verify the animal-friendly status of faux leather products. These certifications help buyers identify products that align with their values.

Vegan Leather Certificate: Certifies that a product contains no animal products and follows environmentally responsible production methods.

Leather Working Group (LWG): Audits tanneries and manufacturers for best practices, focusing on ethical and sustainable production.

Institute of Quality Certification for the Leather Sector (I.C.E.C. Italy): Provides quality assurance for leather and synthetic leather products.

Brazilian Leather Certification of Sustainability (C.S.C.B. Brazil): Promotes sustainable practices in leather and synthetic leather manufacturing.

Leather Standard by Oeko-Tex: Ensures that products meet strict environmental and safety standards.

Sustainable Leather Foundation (S.L.F.): Encourages sustainable and ethical practices throughout the leather industry.

These certifications offer consumers confidence when selecting faux leather goods. Brands that display these labels demonstrate a commitment to ethical sourcing and responsible manufacturing.

Faux leather also supports broader animal welfare initiatives. Animal rights organizations endorse vegan leather as a humane alternative to traditional leather. The fashion industry has responded by increasing the availability of cruelty-free products. Many designers now feature faux leather in their collections, reducing reliance on animal-based materials.

Faux leather provides a solution for individuals who want stylish, durable products without compromising their ethical beliefs. The growing number of certifications and standards ensures that buyers can make informed choices. As demand for animal-friendly materials rises, manufacturers continue to innovate, offering new options that combine performance, aesthetics, and compassion.

Faux leather's animal-friendly qualities contribute to its popularity in global markets. The material allows consumers to express their values through everyday purchases. Brands recognize this trend and invest in certification programs to meet evolving expectations. The result is a diverse range of faux leather products that support animal welfare and ethical consumption.

Durability remains a significant concern for many consumers when evaluating synthetic materials. Faux leather products often show signs of wear and tear sooner than their genuine leather counterparts. The synthetic coating, while resistant to water and scratches, can degrade over time. Repeated bending, stretching, or exposure to sunlight may cause the surface to crack or peel. This process shortens the usable life of many items, especially those subject to frequent use, such as furniture or handbags.

A direct comparison of average lifespans highlights this difference:

|

Material |

Average Lifespan (Years) |

|---|---|

|

Faux Leather |

10 to 20 |

|

Real Leather |

20 to 40 or more |

Manufacturers have improved the quality of synthetic coatings, but real leather still outperforms faux leather in terms of longevity. Consumers who prioritize long-term value may find this difference important when making purchasing decisions.

Breathability refers to a material’s ability to allow air and moisture to pass through its surface. This property affects comfort, especially in clothing, upholstery, and automotive interiors. Genuine leather naturally allows slight moisture exchange, which helps regulate temperature and prevents discomfort during extended use. Faux leather, particularly those made from PU or PVC, lacks this feature.

The following table summarizes laboratory findings:

|

Feature |

Genuine Leather |

Faux Leather (PU/PVC) |

|---|---|---|

|

Breathability |

Slight moisture exchange |

None |

Without breathability, faux leather can trap heat and moisture against the skin. This limitation often leads to discomfort, especially in warm climates or during prolonged contact. Many users notice a sticky or clammy feeling after sitting on faux leather furniture or wearing synthetic leather apparel for extended periods.

Note: Lack of breathability remains one of the most common disadvantages of faux leather, especially in products designed for direct skin contact.

Environmental impact stands out as a major drawback of synthetic leather. The production of faux leather relies on materials such as acrylic and polyester, both derived from fossil fuels. This process contributes to greenhouse gas emissions and increases the carbon footprint of each product. Disposal presents additional challenges. Most faux leather items cannot be recycled easily. When discarded, they accumulate in landfills, where they may release toxic chemicals as they break down.

Manufacturers and consumers alike face growing pressure to address these environmental issues. The lack of sustainable disposal options and the use of non-renewable resources make it difficult to justify widespread use of synthetic alternatives. As a result, many brands now seek innovative solutions, such as recycled or bio-based materials, to reduce the negative impact associated with traditional faux leather.

Cracking and peeling represent some of the most visible and frustrating issues with faux leather. Over time, synthetic leather often develops surface cracks or begins to peel, especially in high-use areas. These flaws not only affect the appearance but also compromise the material’s structural integrity and comfort.

Several factors contribute to the tendency of faux leather to crack and peel:

Aesthetics and Visual Appeal: When faux leather peels, the surface loses its uniform look. Patchy and uneven spots appear, making the product look worn and unattractive. This deterioration can happen quickly if the item receives frequent use or exposure to harsh conditions.

Durability and Structural Integrity: Peeling weakens the material. Once the top layer starts to separate, the underlying fabric becomes vulnerable to further damage. Cracks can expand, leading to tears and holes that shorten the lifespan of the product.

Comfort and Usability: As the surface peels, rough patches develop. These areas can feel uncomfortable against the skin and may even snag on clothing. The usability of furniture, car seats, or apparel made from faux leather decreases as the damage spreads.

Manufacturers design faux leather with a synthetic coating, usually polyurethane or PVC, that mimics the look of real leather. However, this coating lacks the natural elasticity and moisture retention of animal hide. As a result, repeated bending, stretching, or exposure to sunlight and heat can cause the surface to dry out and crack. Low-quality materials and poor manufacturing processes often accelerate this process.

Proper care can help slow down cracking and peeling. The following practices support the longevity of faux leather:

Routine Cleaning and Conditioning: Regularly wipe the surface with a soft, damp cloth. Use mild soap for stubborn stains. Conditioning products designed for synthetic leather help maintain suppleness and prevent drying.

Protection from Direct Sunlight and Extreme Temperatures: Keep faux leather items away from windows, heaters, and direct sunlight. Excessive heat and UV rays accelerate deterioration.

Avoiding Abrasive Materials and Harsh Chemicals: Clean with gentle, non-abrasive tools. Harsh chemicals can strip the protective coating and cause premature peeling.

Using Protective Cushions or Coverings: Place cushions or covers on high-use furniture. These barriers reduce friction and wear, extending the life of the material.

Note: Consistent care and mindful placement can significantly reduce the risk of cracking and peeling in faux leather products.

Despite these preventive measures, faux leather remains more susceptible to surface damage than genuine leather. Consumers should weigh this disadvantage when choosing materials for items that require long-term durability and a pristine appearance.

Manufacturers rely heavily on petroleum-based materials when producing synthetic leather. Polyurethane (PU) and polyvinyl chloride (PVC) serve as the primary components in most synthetic leather products. These polymers originate from fossil fuels, which means their extraction and processing contribute to significant environmental challenges. The use of petroleum-based materials leads to a high carbon footprint during both production and disposal. When synthetic leather items reach the end of their life cycle, they often end up in landfills. Over time, these materials can leach harmful chemicals into the soil and water. Incineration of synthetic leather releases toxic emissions, while microplastic pollution persists in the environment for decades. Unlike natural materials, petroleum-based polymers do not break down easily or return nutrients to the earth. This long-lasting impact raises concerns about the sustainability of synthetic leather in the global market.

Note: The reliance on fossil fuels for synthetic leather production creates persistent environmental risks, including pollution and resource depletion.

The manufacturing process for faux leather generates measurable greenhouse gas emissions. Factories release carbon dioxide and other pollutants during polymer synthesis, coating, and finishing. However, when comparing production emissions, synthetic leather demonstrates a lower environmental impact than traditional cow skin leather. The following table highlights the difference in carbon dioxide equivalent (CO2e) emissions per square meter:

|

Material |

CO2e Emissions (kg per square meter) |

|---|---|

|

Faux Leather |

15.8 |

|

Cow Skin Leather |

110.0 |

|

Difference |

Faux leather is nearly 7 times less impactful than cow skin leather. |

This data shows that faux leather production emits significantly less carbon dioxide than real leather manufacturing. The tanning and processing of animal hides require large amounts of energy and chemicals, which increase the overall carbon footprint. Synthetic leather offers a more efficient alternative in terms of greenhouse gas emissions, although it still relies on non-renewable resources.

Sustainability remains a critical issue for the synthetic leather industry. Companies face pressure to reduce their reliance on petroleum-based inputs and minimize environmental harm. Some manufacturers have started to explore bio-based and recycled alternatives, which use renewable resources or repurposed waste. These innovations aim to lower the carbon footprint and improve the end-of-life options for synthetic leather products. Brands also invest in cleaner production technologies and responsible sourcing to address sustainability concerns. Despite these efforts, the majority of synthetic leather on the market still depends on fossil fuels and lacks effective recycling infrastructure. Consumers and industry leaders continue to seek solutions that balance performance, cost, and environmental responsibility.

Tip: Choosing products made from recycled or bio-based synthetic leather can help support sustainability and reduce environmental impact.

Recycling synthetic leather presents significant challenges for manufacturers, consumers, and environmental organizations. Most faux leather products use polyurethane (PU) or polyvinyl chloride (PVC) as their primary components. These plastics resist decomposition and complicate recycling efforts. When items made from faux leather reach the end of their useful life, they often enter landfills. There, they persist for centuries, shedding microplastics that contaminate soil and water. Microplastics pose a threat to marine ecosystems and can enter the food chain, affecting both wildlife and humans.

The recycling infrastructure for PU and PVC remains underdeveloped. Facilities capable of processing these materials exist in limited numbers. Most municipal recycling programs do not accept synthetic leather goods. The chemical structure of PU and PVC makes them difficult to break down and repurpose. Specialized processes require high energy input and produce secondary waste, which further reduces the appeal of recycling these plastics.

Experts advise against using PVC-based faux leather due to its harmful environmental effects. PVC releases toxic chemicals during production, use, and disposal. These substances can leach into groundwater and contribute to air pollution when incinerated. PU, while less hazardous than PVC, still derives from petrochemicals. It remains nonrenewable and non-biodegradable, offering minimal improvement in terms of recyclability.

Manufacturers have started to explore plant-based alternatives to traditional synthetic leather. Some new materials incorporate natural fibers or bio-based polymers. However, many of these products still contain plastic components. As a result, they do not fully address the recycling problem. The presence of mixed materials complicates sorting and processing, making it difficult to achieve true circularity.

A summary of recycling options for faux leather:

|

Material Type |

Recycling Feasibility |

Environmental Impact |

|---|---|---|

|

PVC Faux Leather |

Very limited |

High, toxic chemical release |

|

PU Faux Leather |

Limited |

Nonrenewable, microplastics |

|

Plant-Based Faux Leather |

Emerging, mixed results |

Often contains plastics |

Tip: Consumers who want to reduce their environmental footprint should seek products made from recycled materials or those designed for easier end-of-life management.

Some brands have begun to offer take-back programs for synthetic leather goods. These initiatives collect used items and attempt to repurpose them into new products. While promising, such programs remain rare and face technical barriers. The lack of standardized recycling methods for faux leather means most products still end up as waste.

The future of recycling synthetic leather depends on advances in material science and infrastructure. Researchers continue to develop new polymers that break down more easily or use renewable resources. Until these innovations reach the mainstream, the environmental impact of faux leather will remain a concern. Manufacturers, retailers, and consumers must work together to support sustainable practices and demand better recycling solutions.

Faux leather serves a wide range of industries due to its versatility and affordability. Manufacturers and designers rely on this material for both style and function.

Fashion brands use faux leather to create jackets, handbags, belts, and shoes. These products offer the appearance of genuine leather at a lower cost. Many designers highlight common uses in fashion by introducing seasonal collections that feature faux leather applications. Consumers appreciate the variety of colors and textures available. Faux leather appeals to those who seek animal-friendly options without sacrificing style.

Furniture makers select faux leather for sofas, chairs, and ottomans. The material resists stains and scratches, making it suitable for high-traffic areas. Faux leather applications in furniture provide a modern look while simplifying maintenance. Homeowners often choose faux leather for its durability and easy cleaning.

Automotive manufacturers incorporate faux leather into car seats, steering wheel covers, and interior panels. The material withstands daily wear and exposure to sunlight. Faux leather applications in vehicles offer a luxurious feel and require minimal upkeep. Many car owners prefer faux leather for its resistance to spills and fading.

Tip: When selecting faux leather products, consider the intended use and environment. Each application benefits from the material’s unique properties.

Proper care extends the life of faux leather items. Owners should follow simple steps to maintain appearance and prevent damage. The following routine demonstrates how to clean synthetic leather:

Wipe the surface with a soft, damp cloth to remove dust.

Apply mild soap for stubborn stains, then rinse with clean water.

Dry the item with a towel to avoid water spots.

Avoid harsh chemicals or abrasive tools that may damage the coating.

A regular cleaning schedule keeps faux leather looking new. For deeper cleaning, use products designed for synthetic materials. Always test cleaners on a small area before full application.

|

Cleaning Step |

Recommended Action |

|---|---|

|

Dust Removal |

Soft, damp cloth |

|

Stain Treatment |

Mild soap, gentle rinse |

|

Drying |

Clean towel |

|

Chemical Use |

Avoid harsh agents |

Note: Consistent cleaning prevents buildup and reduces the risk of cracking or peeling.

Proper storage preserves faux leather and extends its usable life. Owners should keep items away from direct sunlight and heat sources. Excessive exposure causes fading and accelerates deterioration. Store faux leather products in cool, dry places to prevent moisture damage.

Use protective covers for furniture and automotive interiors when not in use. Hang fashion items such as jackets and bags to maintain shape. Avoid folding or compressing faux leather, as this may lead to creases or cracks.

For minor damage, learn how to repair faux leather using patch kits or specialized adhesives. Quick repairs prevent further deterioration and maintain the item’s appearance.

Block Quote: Thoughtful storage and timely repairs help maximize the longevity of faux leather products.

A summary of best practices for storage and care:

Keep away from sunlight and heat

Store in dry, ventilated areas

Use covers for protection

Hang fashion items to retain shape

Repair minor damage promptly

These steps ensure faux leather remains attractive and functional across various applications.

Faux leather offers a practical alternative to genuine leather. Manufacturers use synthetic coatings and fabric bases to create materials that mimic the look and feel of real leather. Key differences include cost, durability, and environmental impact.

Advantages: affordability, easy maintenance, animal-friendly production

Disadvantages: reduced breathability, lower durability, sustainability concerns

Buyers should evaluate their priorities before choosing between faux leather and traditional leather products.

Bonded leather uses shredded leather scraps bonded with polyurethane or latex. Faux leather contains no animal products. Faux leather offers better durability and a more consistent appearance than bonded leather.

Most faux leather products cannot be recycled easily. The material contains mixed plastics like PU or PVC, which complicate recycling. Some brands offer take-back programs, but recycling options remain limited.

Faux leather may crack or peel after repeated use, especially in high-traffic areas. Proper care, such as regular cleaning and protection from sunlight, helps extend its lifespan.

Manufacturers design faux leather to resist water. The synthetic coating repels liquids, making it suitable for furniture and automotive interiors. However, prolonged exposure to moisture may cause damage.

Wipe with a soft, damp cloth.

Use mild soap for stains.

Dry with a clean towel.

Avoid harsh chemicals or abrasive tools to prevent surface damage.

Faux leather contains no animal proteins, so it rarely triggers allergies related to animal hides. Some individuals may react to chemicals used in production. Always check product labels for safety information.

|

Application |

Examples |

|---|---|

|

Fashion |

Jackets, bags, shoes |

|

Furniture |

Sofas, chairs, ottomans |

|

Automotive |

Car seats, interiors |

Faux leather provides versatility across industries due to its durability and cost-effectiveness.

Scan to wechat: