You notice patent leather by its smooth, mirror-like shine. This material stands out in fashion for its bold, glossy surface. Patent leather hides give shoes, handbags, and jackets a modern, eye-catching look. You often see patent leather in formal footwear, belts, wallets, and even outerwear from brands like Hermes and Valentino. Its unique finish adds sophistication and style to many high fashion collections.

Patent leather is known for its high-gloss, mirror-like finish, making it a popular choice in fashion for shoes, bags, and jackets.

The material is durable and waterproof, thanks to synthetic coatings like polyurethane and acrylic, which enhance its shine and flexibility.

Caring for patent leather is easy; simply clean with a damp cloth and use specific polish to maintain its glossy appearance.

Patent leather is versatile and can be worn for both casual and formal occasions, adding a bold touch to any outfit.

Modern production methods have made patent leather more affordable while maintaining its luxurious look and feel.

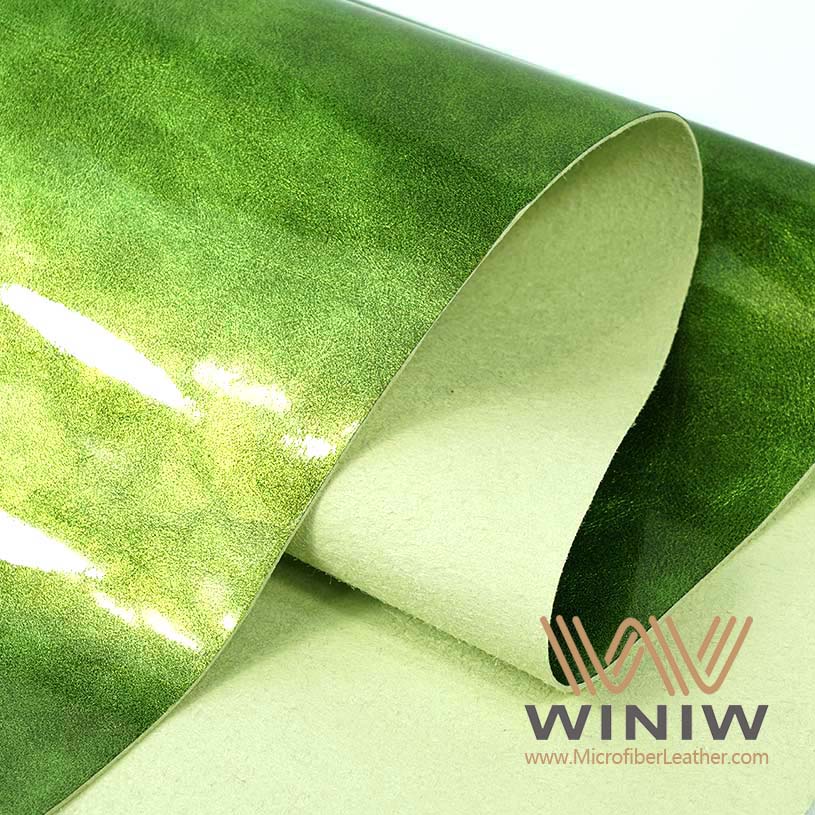

When you look at patent leather hides, you see a material that stands out for its high-gloss, mirror-like surface. Industry standards define patent leather as leather treated with chemicals to achieve a shiny, reflective finish. Most often, manufacturers use cattle hide as the base. They apply a combination of polyurethane and acrylic during the finishing process. This treatment creates a product that feels both durable and flexible. You can recognize patent leather hides by their smooth, almost glassy appearance, which sets them apart from other types of leather.

Patent leather hides offer several features that make them unique in the world of fashion. The most noticeable trait is the glossy finish. This shine comes from multiple layers of lacquer or varnish, which not only create a striking look but also make the surface waterproof. You will find that patent leather resists water and stains much better than untreated leather. The use of synthetic materials like polyurethane and acrylic in modern tanning methods increases both hardness and flexibility. The finish adds thickness to the hide, which can affect how flexible the material feels compared to other leathers. You get a product that combines shine, durability, and a certain level of stiffness, making it ideal for structured fashion items.

Tip: If you want a leather item that stands up to rain or spills, patent leather hides provide excellent water resistance.

You see patent leather hides featured in many areas of fashion. Designers choose this material for its bold look and practical benefits. In recent years, some of the most popular fashion items made from patent leather include jackets, coats, skirts, and accessories. The table below highlights a few standout pieces:

|

Item Description |

Price |

Features |

|---|---|---|

|

Beige Patent Hooded Jacket |

$328 |

Water resistant, oversized fit, chic design |

|

Patent and Shearling Coat |

$399 |

Double breasted, retro style, faux-shearling trim |

|

Patent and Tweed Pencil Skirt |

$124 |

Office wear, versatile color |

|

Croc Embossed Miniskirt |

$99 |

Weekend wear, shiny finish |

You often spot patent leather in high fashion collections from top brands. Designers use it for shoes, handbags, belts, and even outerwear. The glossy surface adds a modern twist to classic silhouettes. You can wear patent leather hides for both formal events and everyday style. The material’s shine and structure help you make a statement, whether you choose a bold jacket or a sleek pencil skirt.

You start making patent leather with a base material, most often cattle hide. Some manufacturers use synthetic or faux leather bases to mass-produce patent leather at a lower cost. The choice of base affects the final product’s feel and durability. Over time, the coatings used on leather have changed. Early methods used natural varnishes, such as linseed oil-based lacquers. Today, you see polyurethane and acrylic coatings as the standard. These synthetic finishes create the high-gloss leather look that defines patent leather. Polyurethane, discovered in the 1930s, brought a major shift in the industry. It improved flexibility, durability, and made the process more efficient. Modern coatings also help make the surface waterproof and resistant to stains.

Note: The shift to synthetic coatings has made patent leather more affordable and accessible, but it can change the unique feel of natural hides.

You can break down the process of making patent leather into several key steps. Each step transforms raw hide into a glossy, finished product:

Preparation of the Hide

You remove the hide from the cow and preserve it in salt. This step prevents decay before further processing.

Curing

You cure the hides in brine for at least 24 hours. This step prepares the hides for shipment to the tannery.

Beamhouse Operations

You soak, dehair, and bate the hides. These actions clean the hides and prepare them for tanning.

Tanning

You soak the hides in a tanning solution, often using chromium salts. This step transforms the hides into leather, making them durable and less prone to decomposition.

Finishing

You apply a polyurethane or acrylic finish to the leather. This coating creates the signature glossy surface of patent leather. Modern factories use vacuum drying and synthetic finishes to ensure a smooth, even shine.

The entire process, from raw hide to finished product, usually takes about 10 working days. Each stage requires careful control to achieve the desired high-gloss finish.

|

Stage |

Environmental Impact Description |

|---|---|

|

Beamhouse |

Requires strict wastewater management due to soaking, liming, and fleshing processes that remove dirt and fat. |

|

Tanning |

Chrome tanning relies on heavy metals, while vegetable tanning uses more water, impacting water resources. |

|

Post-Tanning |

Chemicals used can lead to abiotic depletion and water toxicity. |

|

Finishing |

Coatings and treatments enhance aesthetics but may contribute to environmental degradation. |

|

Thermal Energy Production |

High GHG emissions from fossil fuel use in tanneries, with modern alternatives reducing emissions. |

|

Electricity Sourcing |

Facilities using fossil-fuel-oriented grids have higher environmental impacts; renewable sources can mitigate this. |

|

Chemicals in Processes |

Toxic chemicals and heavy metals can pollute water bodies, especially in areas with inadequate treatment infrastructure. |

Scan to wechat: