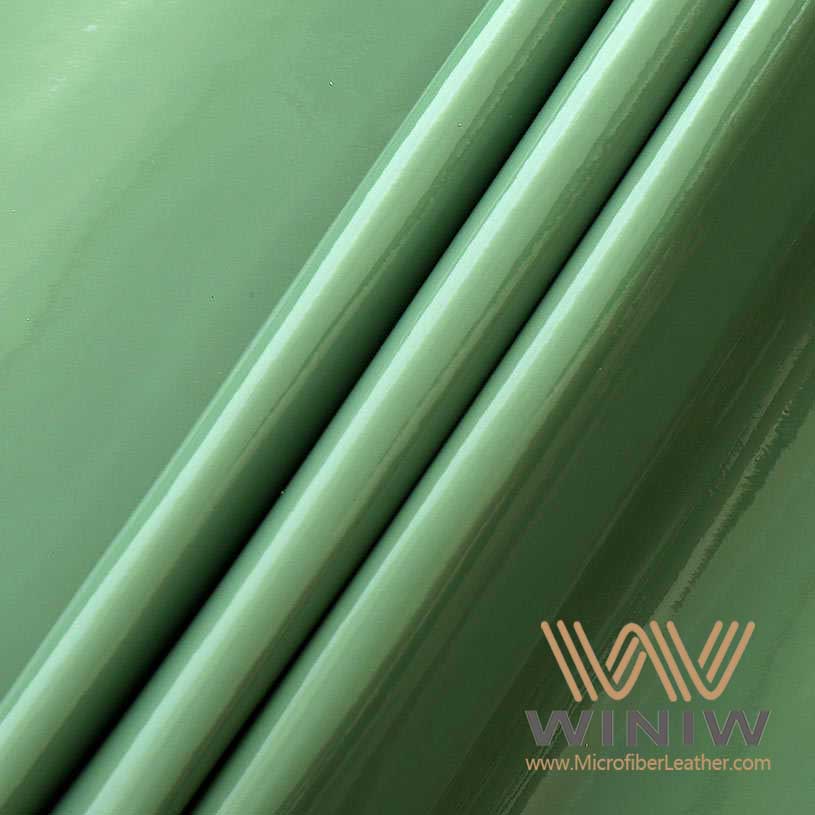

Shiny leather, known as patent leather, features a high-gloss surface and distinct waterproof qualities. Manufacturers achieve this glossy finish by applying a plastic or lacquer coating to natural leather. Patent leather stands out in fashion for its glass-like appearance and smooth texture. The process begins with material selection, by tanning, coating application, and final finishing steps.

Patent leather displays a unique gloss and resists dirt.

The gloss and flexibility make patent leather ideal for formal accessories.

Shiny leather, or patent leather, features a high-gloss finish that is both stylish and waterproof.

The manufacturing process involves applying synthetic coatings to natural leather, enhancing its durability and flexibility.

Patent leather is easy to clean and maintain, making it ideal for shoes, handbags, and formal accessories.

While patent leather resists water and dirt, it can crack or discolor over time if not properly cared for.

Choose patent leather for occasions that require a polished look, but avoid it for items needing high flexibility.

Regular cleaning with leather-safe products helps maintain the glossy finish and extends the lifespan of shiny leather items.

Proper storage in breathable materials prevents mold and preserves the structure of shiny leather products.

Be aware of common care mistakes, such as using harsh cleaners or overloading bags, to keep your shiny leather looking new.

Shiny leather refers to a type of leather with a shiny surface and a high-gloss finish. Manufacturers commonly call this material patent leather. They create patent leather by applying several layers of synthetic coatings, such as polyurethane or acrylic, to natural leather. This process results in a high-gloss leather that stands out for its smooth, polished appearance. The glossy finish makes patent leather virtually waterproof and easy to maintain. The shine comes from the combination of colorants, binders, and finishes, which include pigment pastes, nitrocellulose lacquers, and protein-based finishes. Each layer is baked and polished, producing a durable and flexible high-gloss material.

Patent leather first appeared in the early 19th century. The original process used linseed oil and other additives to achieve the shiny finish. Today, manufacturers rely on advanced chemical coatings for a more consistent gloss and improved performance.

Patent leather displays several features that set it apart from other types of leather. The table below highlights the main differences between patent leather and natural, vegetable-tanned leather:

|

Feature |

Patent leather |

Natural, vegetable-tanned leather |

|---|---|---|

|

Texture |

Smooth, glossy, polished |

Buttery-soft, somewhat oily |

|

Durability |

Resistant to dirt and water, but prone to discoloration and scuffs, and will degrade over time |

Extremely durable, can last a lifetime |

|

Used for |

Predominantly apparel and accessories |

Everything from upholstery to saddlery, briefcases, wallets and footwear |

|

Price |

Generally expensive |

More expensive than inferior varieties of leather |

|

Maintenance |

Very easy to maintain |

Requires semi-regular conditioning to prolong shelf life |

|

Patina |

No patina |

Will form a patina over time |

|

Smell |

Chemical-like |

Rich, earthy |

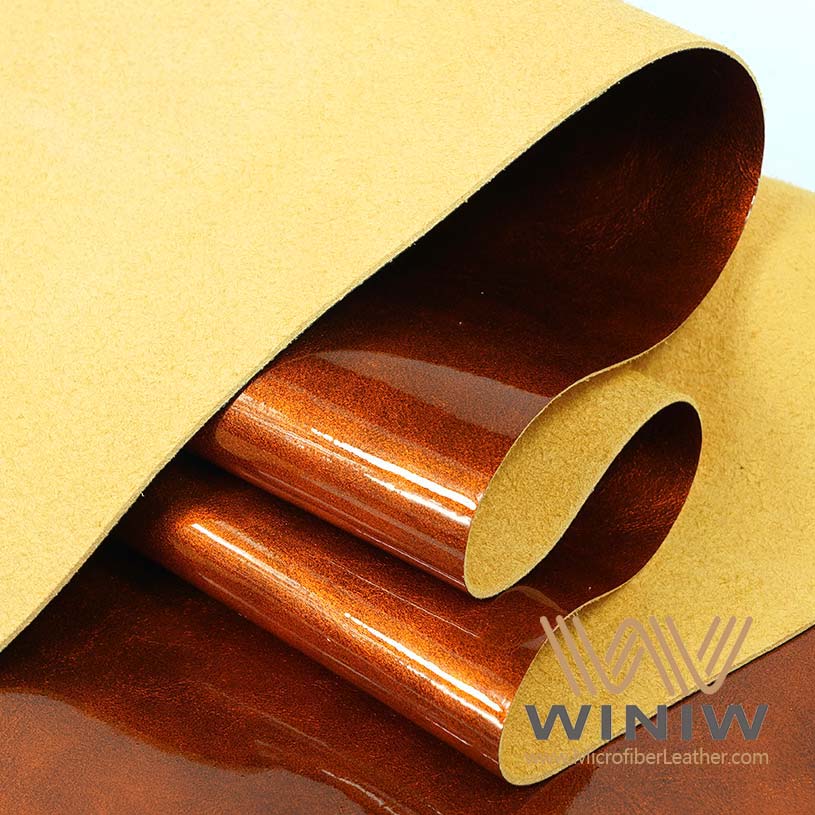

Patent leather features a shiny finish and a glossy surface that resists water and dirt. The synthetic coatings give it flexibility and softness. Unlike natural leather, patent leather does not develop a patina over time. The chemical-like smell also distinguishes it from the earthy scent of vegetable-tanned leather. The gloss remains consistent, but the material can show scuffs and discoloration with heavy use.

Patent leather finds widespread use in several industries due to its unique properties. The shiny leather appeals to designers and manufacturers who want a high-gloss material for luxury products. The most common applications include:

The automotive segment uses patent leather for seats, dashboards, and door panels, especially in luxury vehicles.

The furniture industry prefers patent leather for high-end sofas, armchairs, dining chairs, and headboards because of its durability and luxurious feel.

Footwear manufacturers use patent leather for uppers in sneakers, boots, and casual shoes. Synthetic versions offer lightweight and moldable options.

|

Industry |

Common Applications |

|---|---|

|

Furniture |

Sofas, armchairs, dining chairs, headboards |

|

Automotive |

Seats, dashboards, door panels |

|

Fashion |

Footwear uppers (sneakers, boots, casual shoes) |

Approximately 45% of luxury vehicles sold in 2023 featured leather upholstery. High-end furniture often includes patent leather for its shiny surface and easy maintenance. In fashion, patent leather remains popular for accessories and footwear that require a glossy finish and a touch of elegance.

Patent leather stands as the most recognized type of shiny leather. Manufacturers create it by coating natural leather with layers of synthetic materials, such as polyurethane or acrylic. This process produces a mirror-like surface that resists water and dirt. The history of patent leather stretches back to ancient Mesoamerican civilizations, where artisans used natural oils and tree saps to achieve a semi-glossy finish. In the 1700s, European tanners began applying linseed oil-based lacquers, which required extensive manual buffing. Seth Boyden’s innovations in the early 19th century introduced a refined varnish formula, making patent leather more accessible and consistent. Today, synthetic coatings allow for mass production and improved durability.

Patent leather remains a favorite for formal shoes, handbags, belts, and accessories. Its high-gloss finish and smooth texture set it apart from other leathers.

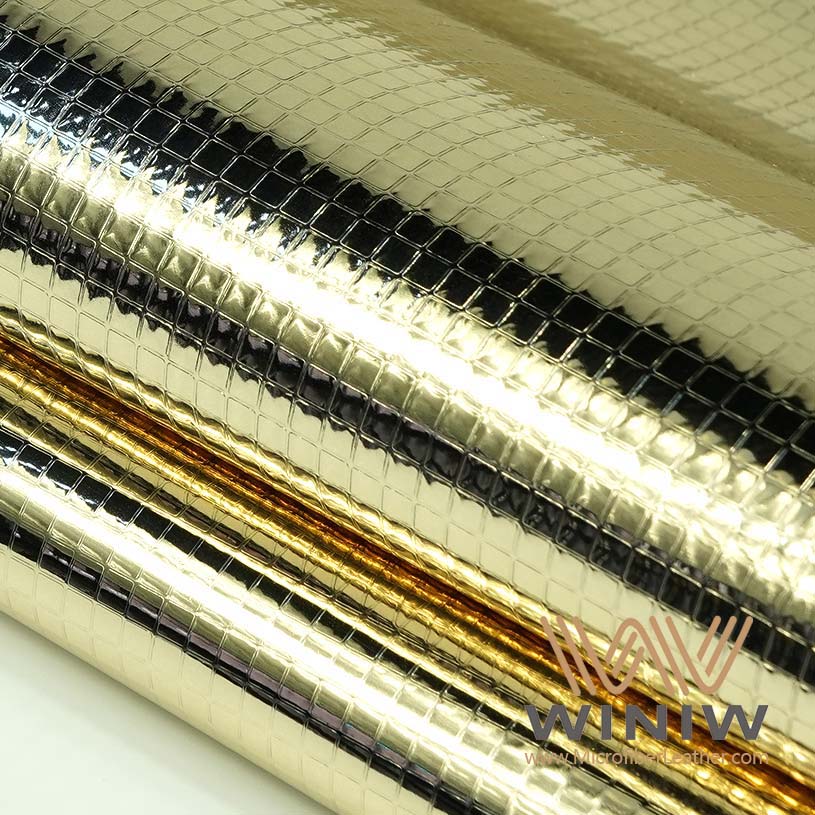

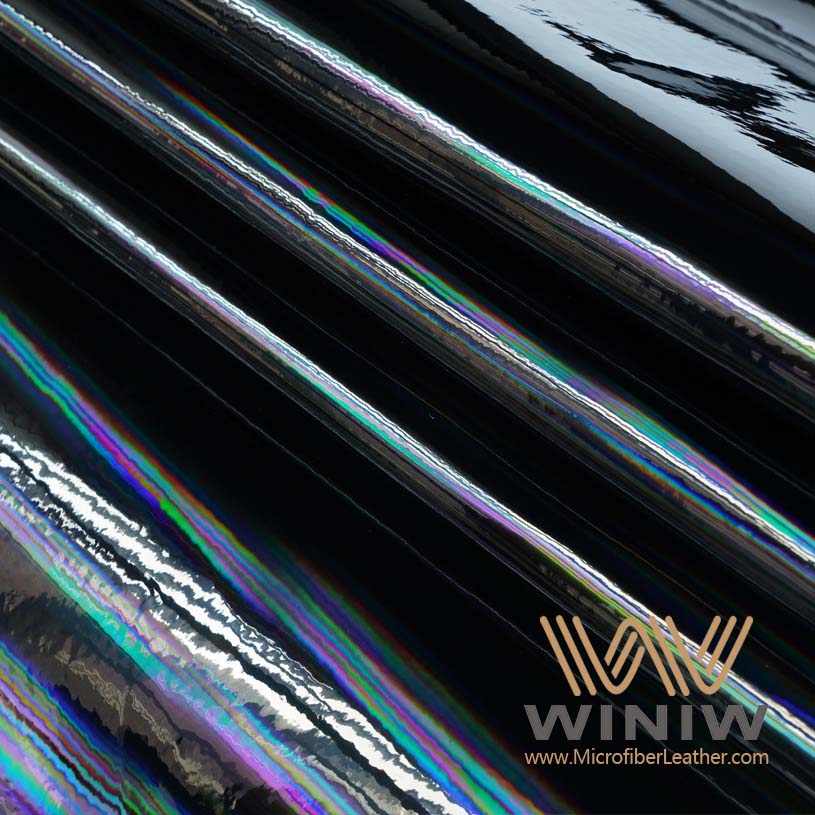

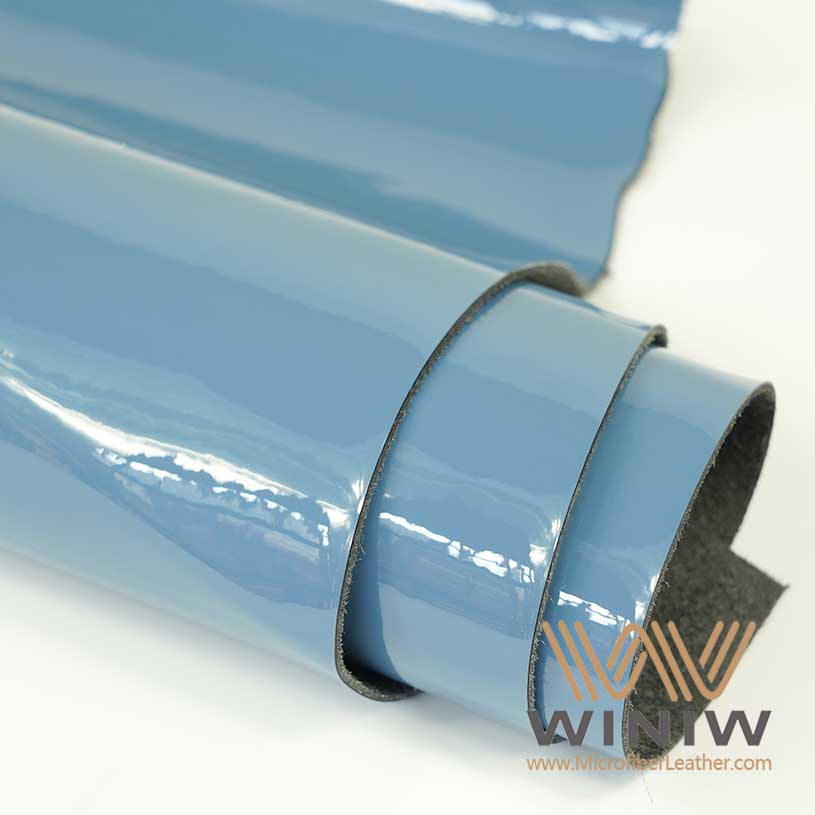

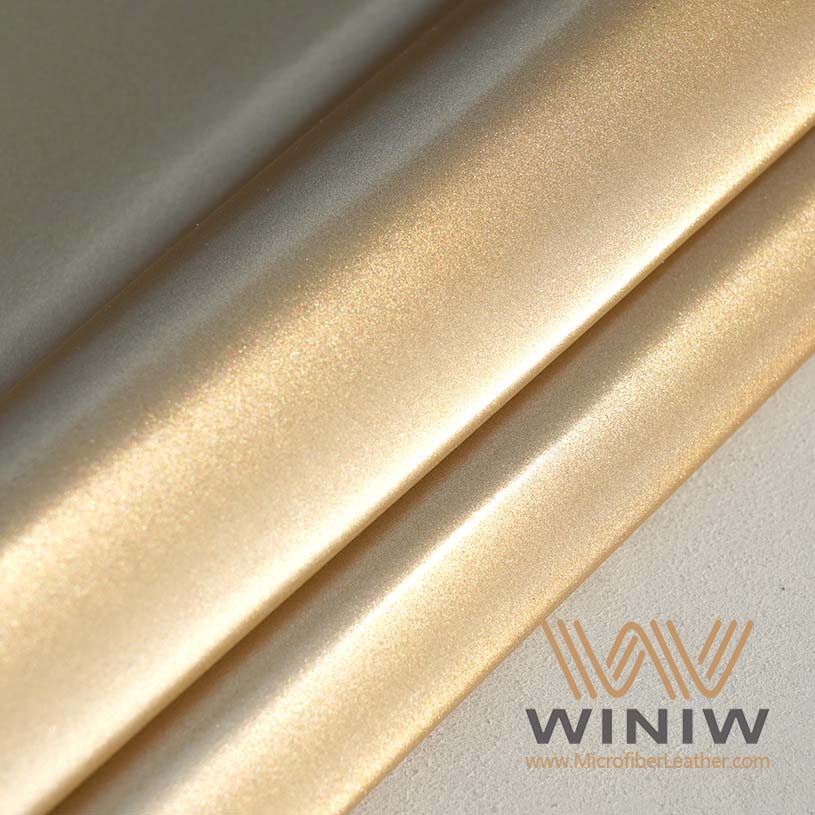

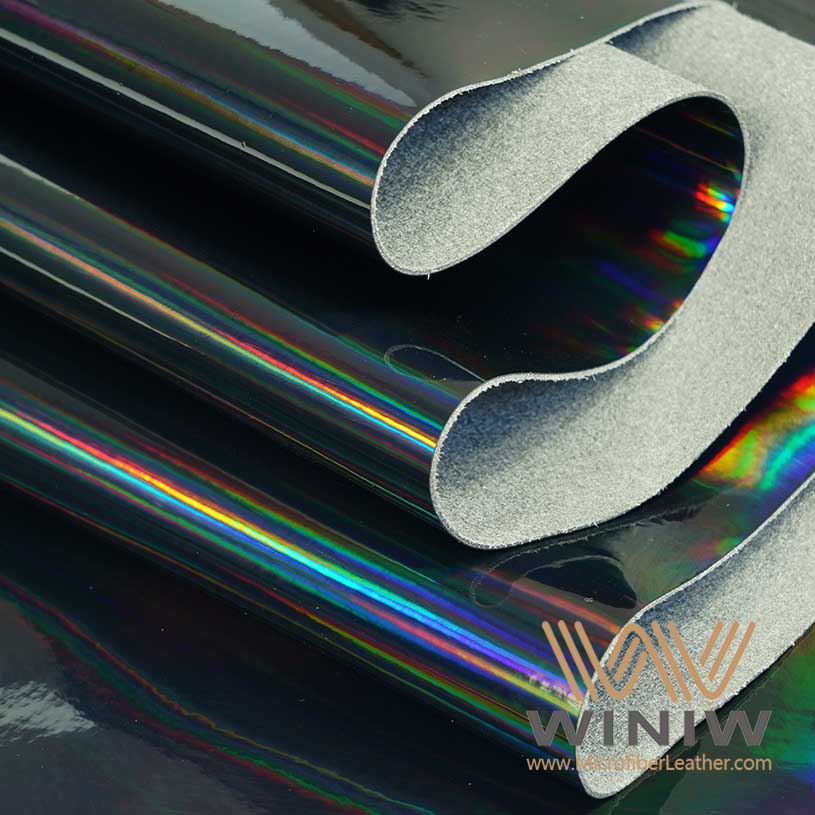

Varnished leather, sometimes called lacquer leather, features a bright, shiny surface achieved by coating genuine or PU leather with paint or lacquer. This type of shiny leather offers a strong surface effect and stands out for its waterproof and moisture-proof qualities. The manufacturing process involves applying a lacquer or paint layer, then curing it to create a durable, glossy finish. Varnished leather often appears in fashion items and decorative accessories.

The table below highlights the differences between common types of shiny leather:

|

Type of Leather |

Material Description |

Characteristics |

|---|---|---|

|

Patent leather |

Coated with synthetic layers on natural leather |

High-gloss, waterproof, flexible, used in fashion |

|

Varnished leather |

Coated with paint or lacquer on genuine or PU leather |

Bright finish, waterproof, easy to clean |

|

Made from the top layer of cowhide |

Soft, used in footwear and luggage |

|

|

Lacquer leather |

Coated with paint on genuine or PU leather |

Strong surface effect, moisture-proof, easy to maintain |

Synthetic shiny leather uses artificial materials to mimic the look and feel of patent leather. Manufacturers often select a base fabric, such as polyester or cotton, for durability. They then apply a coating of polyurethane (PU) or polyvinyl chloride (PVC). PU coatings create a softer, more flexible material, making it popular in fashion. PVC coatings result in a thicker, more rigid product, ideal for upholstery and industrial uses.

Common production methods include roller coating, spraying, and dipping. These techniques ensure an even, glossy finish. Synthetic shiny leather offers a cruelty-free alternative and often costs less than genuine patent leather.

|

Material |

Properties |

|---|---|

|

Polyester/Cotton |

Base fabric for durability |

|

Polyurethane (PU) |

Soft, breathable, flexible, used in fashion |

|

Polyvinyl Chloride(PVC) |

Thick, rigid, highly water-resistant, used in upholstery |

Synthetic shiny leather provides versatility and affordability, making it a practical choice for many industries.

Manufacturers begin the process of making patent leather by carefully selecting the raw materials. The choice of material directly affects the quality and appearance of the final product. They follow a series of important criteria:

Decide on the type of leather to produce, as this determines the necessary ingredients.

Choose high-quality hides that are free from imperfections and have the right thickness and size.

Select a tanning method that matches the desired characteristics of the finished leather.

Pick suitable tanning agents to influence the strength, flexibility, and color of the leather.

Identify finishing agents that will help achieve the desired texture, shine, and color.

Consider the environmental impact of all materials used.

Manufacturers often prefer calfskin or cowhide for patent leather because these hides offer a smooth grain and consistent thickness. High-quality hides ensure the coated leather will have a flawless, shiny surface. The selection of tanning and finishing agents also plays a crucial role in producing a durable and attractive glossy finish.

Tip: The quality of the raw hide sets the foundation for the entire process. Even the best coatings cannot hide flaws in the base material.

The tanning process transforms raw hides into stable, flexible leather suitable for further treatment. Several tanning methods exist, each with unique effects on the final product:

Vegetable Tanning: Uses natural tannins from plants. This method creates eco-friendly leather that develops a unique patina over time. However, it is less water-resistant and often more expensive.

Chrome Tanning: Employs chromium salts for a fast process. This method produces soft, flexible, and water-resistant leather, making it ideal for patent leather. However, it raises environmental and health concerns due to chromium waste.

Chrome-Free Tanning: Uses alternative agents instead of chromium. This method reduces environmental impact but may result in variable quality and higher costs.

Tanning stabilizes the collagen fibers in the hide, preventing decomposition and increasing durability. It also transforms stiff hides into supple leather, which is essential for the flexibility required in patent leather. Proper tanning enhances water resistance, a key feature for items like shoes and handbags. The tanning method also influences the color, grain, and sheen, allowing manufacturers to create a variety of finishes.

|

Tanning Method |

Key Features |

Impact on Patent Leather |

|---|---|---|

|

Vegetable Tanning |

Natural, eco-friendly, develops patina |

Less water-resistant, unique look |

|

Chrome Tanning |

Fast, soft, flexible, water-resistant |

Ideal for patent leather, consistent gloss |

|

Chrome-Free Tanning |

Reduced environmental impact, variable quality |

Used for eco-friendly options |

The coating application stage gives patent leather its signature shiny finish. Manufacturers apply several layers of synthetic coatings to the tanned leather. These coatings create the glossy finish and protect the leather from water and dirt.

The top coating typically contains a dispersed copolymer, which includes:

40 to 70% of an ester of methacrylic acid with C1-8-alkanols

25 to 60% of an ester of acrylic acid with C1-8-alkanols

Up to 3.5% of a C3-C6 α,β-monoethylenically unsaturated carboxylic acid

Up to 4% of auxiliary monomers, such as hydroxypropyl acrylate

At least 40% water by weight

Up to 40% polyurethane top coating composition

Manufacturers may add silicon dioxide or wax to achieve specific effects, such as increased gloss or a softer feel. (Meth)acrylate-based polymer dispersions are popular because they are cost-effective and have low emissions of volatile organic compounds (VOCs).

The process involves applying each layer evenly, then baking or curing the leather to set the coating. Multiple layers build up the shiny surface, resulting in the mirror-like gloss that defines patent leather. This step is crucial in answering the question, "how is patent leather made?" The combination of advanced chemical coatings and precise application techniques ensures a durable, flexible, and attractive coated leather product.

Note: The quality and composition of the coating determine the final appearance and performance of patent leather. Manufacturers must balance gloss, flexibility, and durability to meet industry standards.

The finishing steps in shiny leather production play a crucial role in creating the final look and feel of the product. These steps also determine how well the leather resists wear and tear. Manufacturers follow a series of precise techniques to achieve the signature shine and durability of patent leather.

Impregnation

Workers begin by applying a resin to the leather. This step helps the coating stick better and increases moisture resistance. The resin penetrates the surface, making the leather stronger and less likely to absorb water.

Base Coat

Next, they add a fully pigmented base coat. This layer covers the leather completely and provides a solid foundation for the glossy finish. The base coat also protects the leather from cracking and damage caused by solvents.

Intermediate Coat

After the base coat dries, an intermediate coat goes on. This heavy layer improves the bond between the base and top coats. It also allows for special effects, such as antique finishes, which give the leather a vintage look.

Patent Top Coat

The final step involves applying the patent top coat. Workers use controlled conditions to ensure a flawless, mirror-like surface. This top coat creates the high-gloss finish that defines shiny leather. It also seals the layers below, locking in color and adding extra protection.

Tip: Each finishing step must be performed with care. Even a small mistake can affect the shine and durability of the final product.

The table below summarizes common finishing techniques and their impact on shiny leather:

|

Finishing Technique |

Description |

Contribution to Durability and Appearance |

|---|---|---|

|

Protective Coatings |

Applied to protect leather from water, stains, and scratches. |

Enhances water resistance and extends lifespan by providing a protective barrier. |

|

Gloss Finishing |

Uses gloss-enhancing materials for a shiny appearance. |

Increases aesthetic appeal and provides additional protection against stains. |

|

Matte Finishing |

Results in a non-reflective, natural look. |

Allows natural texture visibility, appealing to consumers seeking authenticity. |

|

Antique Finishing |

Gives leather a vintage look with darker dyes. |

Enhances texture and adds depth, creating a unique aged appearance. |

|

Texturing |

Creates patterns or textures on the leather surface. |

Adds visual interest and allows for customization in high-end products. |

Manufacturers may choose different finishing techniques based on the desired look and use of the leather. For patent leather, gloss finishing and protective coatings are essential. These steps ensure the leather stays shiny, resists water, and lasts longer. The finishing process transforms tanned and coated leather into a product that stands out for both beauty and strength.

Patent leather stands out for its unmistakable glossy appearance. The manufacturing process creates a shiny surface that reflects light, giving shoes, bags, and accessories a mirror-like effect. This gloss comes from multiple layers of synthetic coatings applied to the leather. Designers often choose patent leather when they want products to catch the eye and look luxurious. The glossy finish does not fade easily, so items maintain their vibrant look for a long time. Many people associate the gloss of patent leather with formal events and high fashion. The shine also makes colors appear deeper and more intense than on other types of leather.

Tip: The unique shine of patent leather makes it a popular choice for statement pieces in both fashion and interior design.

Patent leather offers a balance between beauty and strength, but it does not match the durability of traditional leather. The synthetic coating protects the leather from minor scratches and stains, yet it can crack or yellow over time, especially if exposed to heat or sunlight. The table below compares the durability and other features of patent leather with genuine leather:

|

Feature |

Patent Leather |

Genuine Leather |

|---|---|---|

|

Durability |

Generally less durable, prone to cracking and yellowing |

More durable, develops a patina over time |

|

Breathability |

Low breathability |

More breathable, conforms to shape |

|

Water Resistance |

Water-resistant but not waterproof |

Handles moisture better if treated |

|

Flexibility |

Less flexible |

More flexible, conforms to user shape |

|

Scratch Resistance |

Moderate to high scratch resistance |

Varies, marks can enhance appearance |

Patent leather resists surface damage better than some leathers, but it cannot withstand heavy bending or rough use. The coating may peel if not cared for properly. Genuine leather, on the other hand, becomes softer and develops a patina, which adds character over time.

One of the main advantages of patent leather is its resistance to water and dirt. The synthetic coating forms a barrier that keeps moisture and stains from penetrating the leather. This feature makes patent leather ideal for shoes, handbags, and accessories that face daily wear. The shiny surface allows users to wipe away dirt with a damp cloth, keeping items looking clean and new.

Laboratories use several tests to measure the water and dirt resistance of shiny leather. The Maeser Flex test (ASTM D2099) checks how well patent leather resists water during repeated flexing, simulating real-life conditions like rain or humidity. The Water Repellency test (ASTM D1913) and the EN ISO 5403-1 standard also assess how well the material keeps out moisture.

|

Test Name |

Standard |

Description |

|---|---|---|

|

Water Resistance - Maeser Flex |

ASTM D2099 |

Measures resistance to water during flexing |

|

Water Repellency |

ASTM D1913 |

Evaluates how well the surface repels water |

|

Water resistance |

EN ISO 5403-1 |

Tests overall water resistance |

Patent leather’s water and dirt resistance make it a practical choice for people who want stylish products that are easy to maintain. However, it is important to remember that while the material is water-resistant, it is not fully waterproof.

Patent leather offers a unique balance between rigidity and pliability. The flexibility of this material depends on several factors, including the type of leather used, the thickness of the hide, and the specific coatings applied during manufacturing. Manufacturers often choose calfskin or cowhide for patent leather because these hides provide a smooth surface and moderate flexibility. The synthetic coatings, while essential for the glossy finish, can affect how much the leather bends and moves.

The coating process involves multiple layers of polymers, such as polyurethane or acrylic. Each layer adds to the overall stiffness of the leather. Thicker coatings create a more rigid product, while thinner layers allow for greater movement. Patent leather used in shoes and accessories usually features a balance between shine and flexibility. Items like belts or handbags require more pliable leather, so manufacturers adjust the coating thickness to suit the product’s needs.

Note: Flexibility in patent leather does not match that of untreated or natural leather. The synthetic finish limits the leather’s ability to stretch and conform to shapes over time.

The table below compares the flexibility of patent leather with other common types of leather:

|

Leather Type |

Flexibility Level |

Typical Uses |

|---|---|---|

|

Patent Leather |

Moderate |

Shoes, handbags, belts |

|

Full-Grain Leather |

High |

Jackets, wallets, upholstery |

|

Suede |

Very High |

Gloves, linings, casual shoes |

|

Synthetic Shiny |

Variable |

Fashion, upholstery |

Patent leather’s moderate flexibility makes it suitable for structured items that need to hold their shape. Shoes made from patent leather often feel stiffer at first. Over time, the material may soften slightly, but it will never become as supple as full-grain or suede leather. The synthetic coating acts as a barrier, preventing the leather fibers from stretching and adapting to the wearer’s movements.

Manufacturers sometimes add plasticizers to the coating to improve flexibility. These additives help the leather bend without cracking. However, excessive bending or folding can still cause the glossy surface to crease or break. For this reason, patent leather works best for products that do not require frequent flexing.

Key points about patent leather flexibility:

Moderate flexibility compared to natural leather

Coating thickness and additives influence pliability

Best for structured accessories and footwear

Not ideal for items needing high stretch or softness

Patent leather provides a stylish, shiny look with enough flexibility for many fashion and accessory applications. However, consumers should understand its limitations. Choosing the right product for the intended use ensures both durability and comfort.

Shiny leather, especially patent leather, offers several benefits that attract designers and consumers. The most notable advantage is its striking gloss, which gives products a luxurious and eye-catching appearance. Many people choose items with a glossy finish for formal events or to make a bold fashion statement. The manufacturing process creates a surface that resists water and dirt, making maintenance simple.

Industry experts highlight additional advantages in the table below:

|

Advantage |

Description |

|---|---|

|

Durability |

Leather products are known for their strength and can last for years with proper care. |

|

High-quality appearance |

Leather has a unique texture and luxurious feel that is hard to replicate with synthetic materials. |

|

Resistance to wear and tear |

Leather can withstand heavy use and harsh environments, making it ideal for daily wear products. |

|

Breathability and flexibility |

Leather adjusts to body temperature and conforms to shape, providing comfort for extended wear. |

|

Versatility in application |

Leather is used across various industries, including fashion and automotive, showcasing its value. |

|

Biodegradable nature |

Being a natural material, leather is biodegradable and can break down over time. |

Patent leather’s gloss remains consistent over time, so shoes, bags, and accessories keep their vibrant look. The material’s versatility allows manufacturers to use it in fashion, automotive, and furniture industries. Shiny leather also provides a smooth surface that feels pleasant to the touch. Many consumers appreciate the easy cleaning process, as most dirt wipes away with a damp cloth.

Tip: Shiny leather works well for products that need to stand out and maintain a polished look with minimal effort.

Despite its appealing features, shiny leather has several limitations that buyers should consider. The synthetic coating that creates the gloss can reduce the material’s breathability, leading to discomfort during extended wear. Patent leather often has a shorter lifespan than natural leather, especially if exposed to heat or sunlight. The surface may become brittle and lose flexibility over time.

Common disadvantages include:

Short lifespan compared to real leather products.

Environmentally harmful production and disposal.

Lower durability and quality than real leather.

Can become brittle and less breathable.

Shiny leather tends to degrade and is difficult to restore once damaged. The surface is susceptible to scratches and scuffs, which can affect the glossy finish. Discoloration may occur from UV exposure or color migration, especially in brightly colored items. Many users notice a chemical odor due to the plastic coating, which can linger for some time.

Additional drawbacks:

Less longevity than natural leather.

Lack of breathability leading to discomfort.

Unpleasant odor from manufacturing chemicals.

Low heat resistance.

Patent leather does not develop a patina, so it lacks the character that natural leather gains over time. The environmental impact of producing and disposing of synthetic coatings also raises concerns. Consumers should weigh these disadvantages against the benefits before choosing shiny leather for their needs.

Note: Shiny leather works best for occasional use and structured accessories, but it may not suit products that require frequent bending or long-term durability.

Full-grain and top-grain leather represent two of the highest quality options available. Full-grain leather keeps the natural grain and texture, which allows it to develop a unique character over time. Top-grain leather receives a slight sanding to remove imperfections, resulting in a smoother surface. Patent leather, in contrast, features a synthetic coating that creates a glossy, uniform appearance.

The table below highlights key differences:

|

Feature |

Full-Grain Leather |

Top-Grain Leather |

Patent Leather |

|---|---|---|---|

|

Cost |

Typically more expensive, around $50+ |

Usually 20-30% cheaper, around $40-50 |

Often premium-priced, varies |

|

Appearance |

Retains natural texture, develops character |

Smoother finish, less natural appearance |

High-gloss, mirror-like surface |

|

Performance |

Highly durable, ages beautifully |

Less durable, may wear out faster |

Moderate durability, resists water and dirt |

Full-grain leather stands out for durability and breathability. Top-grain leather offers a protective finish that can repel water and stains, but this layer may wear off with time. Patent leather provides a striking shine and easy cleaning, but it does not match the longevity or breathability of full-grain options.

Tip: Patent leather works best for formal accessories, while full-grain and top-grain leather suit everyday items that need to last.

Suede and nubuck offer a soft, velvety texture that appeals to many consumers. Suede comes from the underside of the hide, giving it a plush feel. Nubuck uses the outer layer, which is sanded to create a fine nap. Patent leather, by comparison, feels smooth and slick due to its synthetic coating.

Care requirements differ greatly:

Nubuck requires a soft brush or cloth for cleaning.

Suede needs more intensive upkeep because of its softness.

Both materials are prone to staining, but nubuck is generally more resilient than suede.

Leather creams or polishes should not be used on either nubuck or suede, as these products can damage the surface.

Patent leather resists water and dirt, making it easier to maintain than suede or nubuck. However, it cannot match the comfort or breathability of these softer leathers.

Patent leather excels in situations where style and easy maintenance matter most. Designers often select it for shoes, handbags, and belts that need a bold, glossy look. Shiny leather stands out at formal events, in fashion collections, and in accessories that must resist moisture and stains.

Consider patent leather for:

Occasions that require a polished, eye-catching appearance.

Products exposed to rain or dirt, such as shoes and bags.

Accessories that benefit from simple cleaning routines.

Patent leather does not suit items that need to stretch or breathe, such as jackets or gloves. Full-grain and top-grain leather work better for products that require durability and comfort. Suede and nubuck provide a soft touch for casual wear, but they demand careful maintenance.

Note: Shiny leather offers a unique combination of style and practicality, but users should match the material to their needs for the best results.

Proper cleaning helps maintain the appearance and longevity of shiny leather. Dirt and grime can dull the gloss if left untreated. Regular care keeps the surface looking vibrant and prevents buildup. The following table outlines effective cleaning methods for shiny leather products:

|

Cleaning Method |

Description |

|---|---|

|

Specialized Patent Leather Cleaner |

Targets surface buildup without damaging the protective coating, removes grime, and smooths scuffs. |

|

Wax Remover |

Dissolves waxy buildup for a softer finish; requires careful application to avoid damage. |

|

Petroleum Jelly |

Creates a satin-like glow by diffusing light; should be used sparingly to avoid residue. |

|

Acrylic Matte Finishing Spray |

Provides a permanent matte finish and protects against moisture and scratches; requires careful application. |

A specialized cleaner designed for coated leather works best for removing dirt while preserving the gloss. Wax removers help eliminate stubborn residue, but users should apply them gently. Petroleum jelly can add a subtle glow, though excessive use may leave a sticky film. For those seeking a matte look, acrylic sprays offer protection and a different finish.

Tip: Always test cleaning products on a small, hidden area before applying them to the entire surface.

Protecting the finish of shiny leather ensures the gloss remains intact and prevents scratches or fading. Several treatments help reinforce the topcoat and shield the surface from daily wear. Recommended products include:

A leather protector like Guardsman Leather Protect & Preserve creates an invisible, breathable shield. This treatment repels water, body oil, and debris.

UV protection in these products helps reduce damage from sunlight, keeping the gloss vibrant.

Regular application of a protector maintains the coated leather’s durability and appearance.

Manufacturers advise using protectors every few months, especially for items exposed to sunlight or moisture. These treatments extend the life of shiny leather and keep accessories looking new.

Note: Avoid harsh chemicals or abrasive cloths, as they can scratch the surface and diminish the gloss.

Storing shiny leather correctly prevents cracking, mold, and loss of gloss. Long-term storage requires attention to temperature, humidity, and wrapping materials. Experts recommend the following practices:

Use acid-free tissue paper for stuffing and wrapping. Paper absorbs moisture and prevents mold, while plastic can trap humidity and cause damage.

Choose climate-controlled storage. A cool environment with regulated humidity protects coated leather from warping or cracking.

Maintain optimal temperature and humidity. Store leather at 60 to 70 degrees Fahrenheit to avoid mold growth and keep the gloss intact.

Wrap or cover items with cotton or acid-free tissue. Place them in boxes for extra protection against dust and light.

These steps help preserve the structure and shine of shiny leather products. Proper storage ensures that bags, shoes, and accessories retain their gloss and remain free from damage.

Tip: Never fold shiny leather items during storage. Creases can permanently affect the coated surface and reduce the overall appearance.

Many consumers want to keep shiny leather looking new, but they often make mistakes that can shorten the life of their products. Shiny leather, especially patent leather, needs special care to maintain its gloss and structure. Understanding the most common errors helps prevent damage and keeps accessories in top condition.

Common mistakes when caring for shiny leather include:

Using Household Cleaning Products:

Some people use regular household cleaners on shiny leather. These products often contain harsh chemicals that strip away the protective coating and dull the shine. Leather-safe cleaners protect the finish and preserve the gloss.

Ignoring Leather Type-Specific Care:

Shiny leather has different needs than other types. Many consumers treat all leather the same, which can lead to cracking or discoloration. Learning about the specific care requirements for patent leather helps avoid these problems.

Overloading Leather Bags:

Bags made from shiny leather can lose their shape if overloaded. Heavy contents stretch the material and cause permanent distortion. Owners should avoid carrying excessive weight to maintain the bag’s structure.

Storing Leather in Plastic Bags:

Plastic traps moisture and creates an environment for mold growth. Shiny leather needs to breathe. Storing items in breathable fabric bags or wrapping them in acid-free tissue paper prevents mold and keeps the leather healthy.

Not Consulting a Professional for Repairs:

Attempting DIY repairs on shiny leather can worsen damage. Scratches, cracks, or peeling often require expert attention. Professional repair services use specialized tools and products to restore the finish without causing further harm.

The table below summarizes these mistakes and their recommended solutions:

|

Mistake |

Why It’s Harmful |

Solution |

|---|---|---|

|

Using household cleaners |

Damages coating, dulls shine |

Use leather-safe cleaners |

|

Ignoring type-specific care |

Causes cracking, discoloration |

Learn care for patent leather |

|

Overloading bags |

Distorts shape, stretches leather |

Avoid excessive weight |

|

Storing in plastic bags |

Traps moisture, causes mold |

Use breathable fabric bags |

|

DIY repairs |

Worsens damage |

Seek professional help |

Tip: Regularly inspect shiny leather items for early signs of wear. Quick action prevents minor issues from becoming major problems.

Avoiding these mistakes helps shiny leather products stay glossy, flexible, and attractive for years. Owners who follow proper care routines enjoy longer-lasting accessories and maintain the luxurious look that makes shiny leather so popular.

Patent leather stands out for its glossy finish, water resistance, and easy cleaning. Manufacturers achieve this look by coating leather with plastic or lacquer. Shiny leather products offer style and practicality, but they can scuff and require proper care. Regular use of leather care products extends their lifespan by up to 40%. Consumers should choose shiny leather for formal events or when easy maintenance matters most. Younger buyers often seek sustainable options, while older shoppers value durability and craftsmanship.

Shiny leather, often called patent leather, features a synthetic coating that creates a glossy finish. Regular leather does not have this coating and usually appears matte or slightly shiny. Patent leather also resists water and dirt better than untreated leather.

Yes, shiny leather can crack or peel, especially if exposed to heat, sunlight, or frequent bending. Proper care, such as regular cleaning and storage in cool, dry places, helps prevent damage and extends the life of the material.

Use a soft, damp cloth to wipe away dirt. For stubborn stains, apply a cleaner made for patent leather. Avoid harsh chemicals or abrasive sponges. Always dry shoes with a soft towel after cleaning.

Shiny leather works best for occasional or formal use. Daily wear may cause scuffs, creases, or loss of gloss. Many people choose it for special events or accessories that do not require frequent bending.

Manufacturers produce shiny leather in many colors, including classic black, white, red, and metallic shades. The coating process allows for a wide range of vibrant and unique finishes.

Minor scratches sometimes buff out with a soft cloth or a patent leather conditioner. Deep scratches or peeling usually require professional repair. Attempting to fix major damage at home may worsen the problem.

Patent leather production uses chemicals and synthetic coatings, which can impact the environment. Some manufacturers now offer eco-friendly options with water-based coatings or recycled materials. Consumers should check product labels for sustainability information.

Avoid using oils, alcohol-based cleaners, or rough brushes. These products can dull the shine or damage the coating. Stick to cleaners and conditioners designed specifically for patent leather.

Scan to wechat: