You see car head liners every time you look up inside your vehicle. This soft, fabric-covered layer attaches to the ceiling and shapes how your car feels and looks.

Many drivers want interiors that feel quiet, comfortable, and stylish.

Automakers now use advanced headliners to reduce noise, improve looks, and add a premium touch.

Headliners also help absorb sound, making your ride smoother and more relaxing.

When you know how headliners have changed, you can appreciate their impact on your driving experience.

Car head liners enhance comfort by reducing noise and vibrations, making your ride smoother.

Modern head liners integrate advanced technology, such as sensors and ambient lighting, to improve your driving experience.

Choosing the right head liner material can elevate your car's interior style and comfort, so consider options like perforated cloth for a premium feel.

When you step inside most modern automobiles, you notice the smooth, fabric-covered surface above your head. This is the car head liner. In simple terms, a car head liner is the panel that covers the interior roof of your vehicle. You see it every time you look up while driving or riding. The automotive headliner consists of a layer of fabric or synthetic material bonded to a foam or composite backing. This design gives your car a finished look and helps create a comfortable environment. The automotive industry relies on headliners to make vehicles feel more inviting and to support other features inside the cabin.

Tip: If you want your car to feel quieter and cooler, pay attention to the head liner material. It plays a big role in your driving comfort.

Car head liners serve several important purposes in automobiles. You might think they only make the interior look nice, but they do much more. The automotive industry uses headliners to improve both the appearance and the function of vehicles. Here are the main reasons manufacturers include headliners in automotive designs:

|

Feature |

Description |

|---|---|

|

Enhanced Interior Comfort and Noise Reduction |

Engineered to improve acoustic insulation, reducing road noise and vibrations, especially in electric vehicles. |

|

Integrated Lighting and Mood Settings |

Ambient lighting embedded within headliners allows customizable interior atmospheres, enhancing user experience. |

|

Sensor and Connectivity Integration |

Modern headliners host sensors for climate control and biometric authentication, supporting advanced features. |

|

Advanced Safety Features |

Equipped with airbags and crash sensors to improve safety during collisions. |

|

Personalization and Aesthetic Customization |

Customizable fabrics, colors, and patterns to meet consumer demands for personalized interiors. |

You experience the benefits of car head liners every time you drive. The automotive headliner helps block outside noise and keeps the cabin temperature stable. Manufacturers in the automotive industry use special materials that absorb sound and reduce vibrations. For example, some headliners combine thermal and acoustic barriers, which minimize road noise and keep the interior cooler. This makes your ride smoother and more relaxing.

Car head liners also support advanced technology in modern automobiles. You find sensors, lighting, and even airbags built into the headliner. The automotive industry continues to innovate, adding new features that improve safety and comfort. You can choose from different fabrics, colors, and patterns to match your style. This level of customization shows how important headliners have become in the design of automobiles.

You can trace the roots of automotive headliners back to the earliest cars, where simple cloth or canvas stretched across the roof. These basic materials offered little comfort or style, but they marked the beginning of a long journey in automotive heritage. Early headliners had historical significance because they set the foundation for future innovation. As you look at the evolution, you see how the automotive industry experimented with different fabrics and padding to improve the driving experience.

|

Material Type |

Description |

Impact on Vehicle Design |

|---|---|---|

|

Composite Material |

A combination of face fabric with nonwoven or foam backing. |

Provides aesthetics and sound reduction. |

|

Tricot Knit Fabric |

A soft-touch fabric that is napped for uniform appearance. |

Enhances comfort and visual appeal. |

|

Polyurethane Foam |

Used as a backing material for headliners. |

Contributes to safety through head impact counter measures. |

|

Environmentally Friendly |

Recent developments include recyclable materials. |

Supports sustainability in vehicle design. |

You notice major changes in automotive headliners as technology advances. The introduction of synthetic fabrics, such as polyester, made headliners more durable and affordable. For example, switching to solution-dyed polyester reduced material costs by 12% for a leading electric vehicle manufacturer. Adhesive technology also transformed the automotive industry. Adhesive films now provide strong, clean bonds for headliners. These films resist heat and humidity, which means your headliner lasts longer and performs better. The cleaner production process supports sustainability and reflects the historical significance of innovation in automotive heritage.

Adhesive films offer excellent bonding and durability.

They are solvent-free and VOC-free, making production safer.

Thermal activation ensures strong adhesion and longevity.

Today, you find advanced composite materials in automotive headliners. These materials combine lightweight strength with flexibility, improving both efficiency and comfort. Modern composites use glass or carbon fibers, thermosetting or thermoplastic resins, and even natural fibers for eco-friendly options. You benefit from headliners that are lightweight, strong, and versatile. The automotive industry continues to push boundaries, integrating new materials that shape the future of automotive heritage.

|

Property |

Description |

|---|---|

|

Lightweight |

Designed for lightweight applications, improving vehicle efficiency. |

|

Strength |

Increased strength due to polyurethane core chemistry. |

|

Stiffness |

Enhanced stiffness at a total thickness of 4mm, improving feel and touch of the headliner. |

|

Versatility |

Can integrate with various A-surface fabrics and standard manufacturing equipment. |

|

Thermoformable |

Capable of being shaped under heat, allowing for complex designs. |

You see how the automotive headliner has evolved from simple beginnings to a key part of vehicle design, reflecting both technological progress and historical significance.

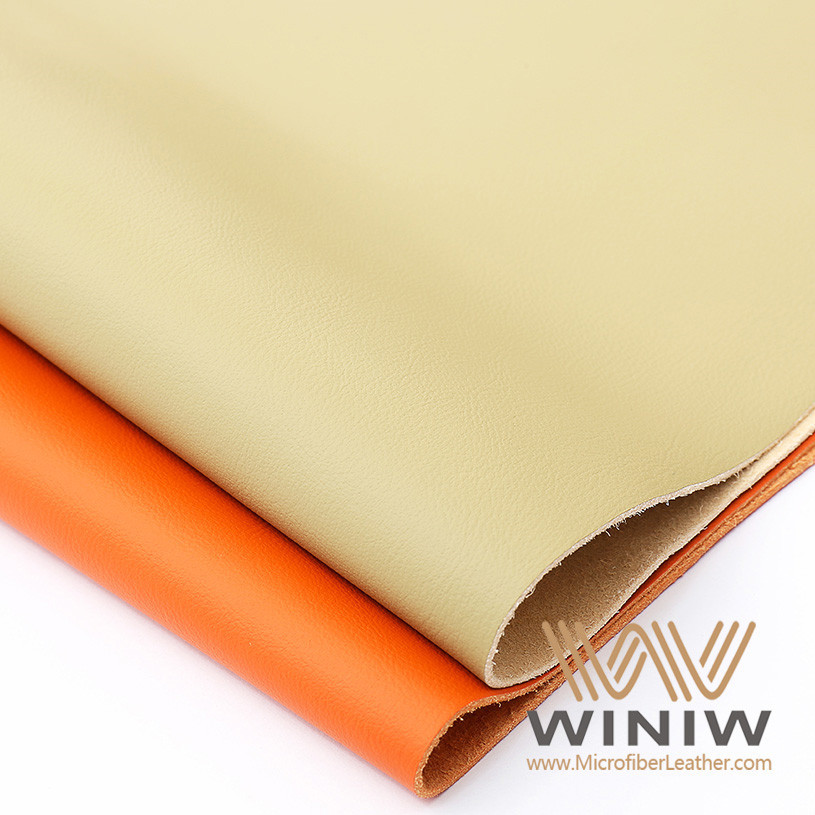

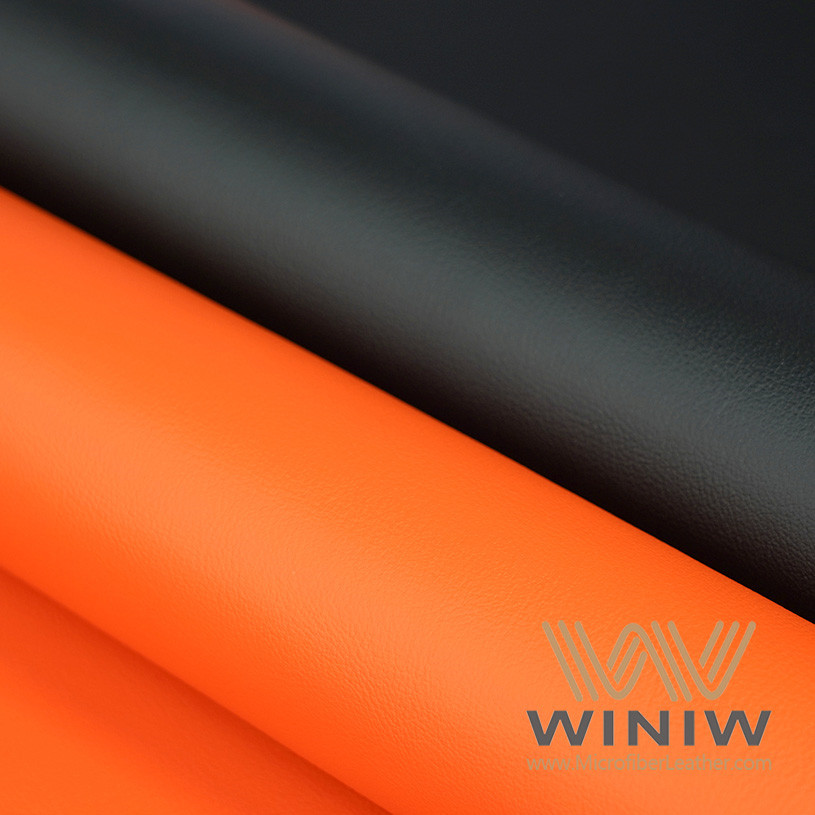

You find a variety of materials used in automotive headliners. Manufacturers select these materials based on comfort, durability, and style. The most popular options include foam-backed cloth, cotton-napped cloth, synthetic cloth, and perforated cloth. Each material offers unique benefits for different vehicle types and interior designs.

|

Material Type |

Description |

|---|---|

|

Foam-backed cloth |

Versatile and compatible with various applications, holding a prominent market share. |

|

Cotton-napped cloth |

Commonly used for its aesthetic appeal and comfort. |

|

Offers durability and resistance to wear and tear. |

|

|

Perforated cloth |

Provides breathability and is often used in high-end vehicles for a premium feel. |

When you consider costs, basic fabric options such as woven cloth or nylon blends remain the most affordable. Vinyl adds water resistance at a slight premium. Genuine leather starts around $1,000 per seat and can exceed $3,000 for luxury models. If you choose custom headliner fabric for a DIY project, expect to spend $60 to $200. Professional installation for sedans ranges from $250 to $600, while larger vehicles may cost $500 to $1,000 or more.

Tip: If you want a premium look and feel, perforated cloth or Alcantara can upgrade your automotive interior, but these options cost more.

You see two main construction methods for automotive headliners. Composite hard-backed headliners use multiple layers fused together. These components include a base layer of fiberglass or hardboard, a foam layer, and a top fabric layer. This method increases durability and allows for features like dome lights and noise reduction. Soft-backed headliners consist of a single layer of fabric or vinyl without a molded backing. Manufacturers use these less often in modern vehicles.

Composite hard-backed headliners provide strength and integrate advanced components.

Soft-backed headliners offer simplicity but less durability.

Manufacturers rely on precise cutting and shaping to ensure headliner components fit perfectly. Automated machinery improves production efficiency and reduces waste. Multiple layers in assembly enhance soundproofing and insulation. During installation, integrated features like lighting and sensors boost both function and appearance. Quality control and testing guarantee that automotive headliners meet safety and durability standards before final assembly.

You now understand how car head liners shape your classic car experience and support classic car restoration. Their evolution impacts resale value and satisfaction, as shown below:

|

Trend |

Impact on Resale Value and Consumer Satisfaction |

|---|---|

|

Sustainable Materials |

Appeals to environmentally conscious consumers, potentially increasing resale value. |

|

Smart Technology Integration |

Enhances functionality and aesthetics, leading to higher consumer satisfaction. |

|

Lightweight Designs |

Improves fuel efficiency, which can be a selling point for resale value. |

|

Customization |

Allows for personalized interiors, increasing consumer satisfaction and perceived value. |

|

Advanced Manufacturing |

Reduces costs and improves design flexibility, potentially enhancing vehicle appeal. |

When you know about headliners, you make better choices for durability and maintenance:

Durability matters for long-lasting interiors.

Maintenance affects how easy it is to keep your car looking great.

You often see sagging when the adhesive fails or moisture damages the components. Regular care helps you maintain a better classic car experience.

You can replace it with basic tools and patience. Many people try classic car restoration projects by installing new headliner components at home.

Head liners absorb sound and insulate heat. You notice a quieter ride and cooler cabin, which improves your classic car experience.

Scan to wechat: